What Is a Compression Reducer?

A compression reducer is a device that compresses waste by applying high pressure to reduce its volume. By applying high hydraulic pressure, refuse that would otherwise take up a lot of space can be compacted. In addition to reducing waste storage space, it can also reduce the cost of waste collection and transportation. They are especially used at food processing sites, construction sites, and plastic product factories where large amounts of waste are generated. In addition, large size machines are used in direct connection with production lines.

Uses of Compression Reducers

Compression reducers are used in places where large amounts of waste are generated. An example is a building materials processing plant. The site generates a large amount of lumber and wood waste, making waste disposal very difficult. However, by using compression reducers, the volume of waste is reduced and costs are reduced. They are also widely used in plastic product manufacturing plants.

Plastic and Styrofoam can be greatly reduced in volume by compressing them. In addition, since they can be compacted without heat treatment, they can be recycled.

Principle of Compression Reducers

Compression reducers are used to compress and reduce the volume of refuse. Here, we introduce the principles and features of compressing various types of refuse.

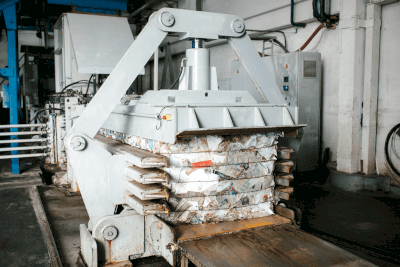

Refuse placed in a sealed space is compressed by tens of tons of high hydraulic pressure. The principle is simple: the volume is reduced by being crushed by the compression plates. Large-scale equipment is capable of compressing more than 500 kg of refuse at a time, and is directly connected to the production line of a factory.

Brittle refuse such as styrofoam is crushed before being compacted. The waste is broken into small pieces by passing through a crushing section with large blades and is then compacted. After compaction, the waste is evenly distributed, making it easier to transport and process. This method is also environmentally friendly, as it does not interfere with recycling because it is processed without the addition of heat. However, some heat is generated by friction during compression, so cooling water must be used.

In addition, there are smaller devices that can be used easily. These devices can compress paper, plastic bottles, cans, etc., and are installed in offices and commercial facilities.