What Is a Pump for Liquid?

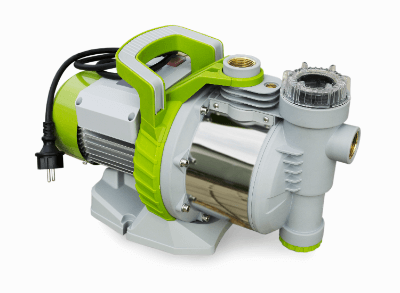

Pumps for Liquid are devices used to move liquids.

Most pumps are Pump for Liquid because they are generally devices intended for liquids. They suck up a liquid, apply pressure to it, and then pump it through pipes and tubes to another location. Pumps for Liquid are capable of efficiently suctioning and pumping liquids.

They can handle a wide variety of liquids, including water, chemicals, and petroleum. In addition, modern Pumps for Liquid are compatible with automation technology and can often be operated and controlled automatically in conjunction with sensors and controllers. Remote control is also possible, allowing monitoring and operation from remote locations.

However, it is important to select the appropriate type according to the nature of the liquid and the intended use. Wrong pump selection may cause poor performance or failure.

Applications of Pumps for Liquid

The list of applications for Pumps for Liquid is endless. The following are just a few examples of applications for Pump for Liquid

1. Water Supply

Pumps are used to supply water for general household and industrial applications. They pump up well water and groundwater to supply water to buildings and agricultural land. Pumps are also used for water purification and wastewater treatment, often to discharge sewage and operate water purification plants.

2. Plant

Pumps are required in the extraction and transportation of oil and gas. In particular, high-pressure pumps are used to transport crude oil and heavy oil. Pumps made of special materials are also used in chemical plants to process various liquids and chemicals.

3. Food Processing

Used to fill food and beverage containers with liquids. It can be applied to liquids with high viscosity. They are also used as squeeze pumps to squeeze liquids such as juices and seasonings from fruits and raw materials.

Principle of Pump for Liquid

The basic principle common among Pump for Liquid pumps is that the pump sucks up liquid, compresses it, and then pumps it to another location. All Pumps for Liquid have a mechanism for sucking up liquid. This is done by creating a space within the pump and drawing the liquid into that space. A drop in pressure inside the pump causes the liquid to be sucked up.

The sucked-up liquid is pressurized inside the pump. This compression increases the energy of the liquid and provides the pressure necessary to pump the liquid.

The compressed liquid is then pumped out through an outlet in the pump to another location. Valves or valves are sometimes used to control the flow of liquid.

Types of Pumps for Liquid

There are many different types of Pumps for Liquid. The following are examples of types of Pumps for Liquid

1. Gear Pump

A gear pump is a pump in which gears engage each other to move liquid; when one gear rotates, the driven gears rotate simultaneously. The space between the gears sucks up the liquid, and the rotating gears compress the liquid and send it to the outlet.

Viscous liquids can be moved efficiently. Widely used to supply lubricating oil and fuel.

2. Piston Pump

This pump uses a combination of a piston and cylinder to move liquid. The reciprocating motion of the piston inside the cylinder sucks up the liquid and changes the pressure inside the cylinder. The movement of the piston compresses the liquid, which is then pumped out through the outlet port.

This is advantageous when using high pressure or when accurate flow control is required. Widely used for liquids with high viscosity.

3. Diaphragm Pump

This pump uses a movable diaphragm to suck up liquid and compress and discharge it. The diaphragm can seal the contact area with the liquid. Therefore, they are suitable for handling special liquids such as chemicals, corrosive liquids, and liquids containing solids.

4. Volute Pump

This pump sucks in liquid by means of rotating blades and pushes the liquid outward by centrifugal force. The shape of the blades causes the liquid to flow inside the pump in a spiral shape. This characteristic prevents agglomeration of solids as the liquid moves slowly through the pump while rotating.

They are often used in applications that require a high flow rate and not much pressure.