What Is a Throttling Valve?

A throttling valve is a device used to control the fluid inside a pipeline. Installed in a pipeline or conduit through which fluid passes, it regulates the flow of fluid by narrowing or widening the internal passage.

Throttling valves allow the required flow rate to be secured and controlled by changing the degree of opening. This can improve process efficiency and fluid system stability.

In addition, they generally have a simple structure and are relatively easy to operate. There are a variety of operating means to change the degree of opening, including handles and electric actuators. These means of operation allows for easy control.

However, since throttling valves restrict the passage of fluid, there is a pressure drop across the passing fluid. The more the valve is closed, the more the pressure drop increases, often affecting the efficiency of the fluid transfer. Cavitation can also occur due to localized pressure drops as high velocity fluid passes through a throttling valve.

Uses of Throttling Valves

Throttling valves are used in a variety of industries and fields. The following are just a few examples of throttling valve applications:

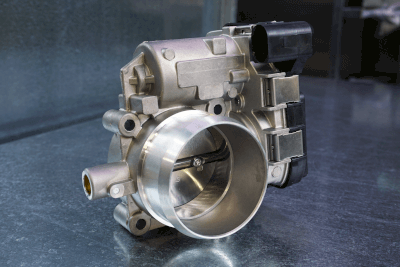

1. Automobiles

Automotive engines constantly calculate the ideal amount of air for the fuel supply in order to achieve optimal combustion. A throttling valve is often used as a tool to adjust the air supply. As the accelerator pedal is depressed, the throttling valve is opened to supply more air into the combustion chamber.

This allows more fuel to be burned and higher power output to be obtained. In recent years, technology has also been introduced to control vehicle speed by automatically controlling the throttling valve opening.

2. Plants

In chemical plants, they are used to control the supply and discharge of liquids and gases, as well as reaction processes. One example is often used to control the pressure and flow rate in a reactor. They are also used in oil refineries to control the flow of crude oil and pressure in the refining process.

3. Power Plants

Throttling valves are also important devices in power plants. In power plant steam turbines, throttling valves control steam flow and pressure to optimize power generation and turbine efficiency. They are also often used in power plants to control the flow of cooling water used and to make the heat exchange process more efficient.

Principle of Throttling Valves

The basic principle of throttling valves is to control flow and pressure by restricting the passage of fluid through the valve by means of the opening of the valve plug. The specific principle varies depending on the type of throttling valve.

However, most throttling valves restrict the passage of fluid by the degree of opening of the valve plug. By changing the valve disc opening, the cross-sectional area of the passage can be adjusted to control the flow of fluid.

Throttling valves are also installed in pipelines and piping systems to restrict the passage of fluids. Closing the valve plug narrows the passage and restricts the flow of fluid. Conversely, opening the valve plug widens the passage and facilitates fluid flow.

Fluid passing through the throttling valve experiences a pressure drop because of the restricted passage. In most cases, the pressure loss increases as the valve plug is closed. This pressure drop depends on the design and characteristics of the throttling valve.

Types of Throttling Valves

There are several types of throttling valves. The following are examples of throttling valve types:

1. Globe Valve

This throttling valve controls fluid flow by moving the cylindrical valve plug up and down. It is widely used because it allows stepless flow control. However, the problem is that it causes high pressure loss.

2. Butterfly Valve

This throttling valve opens and closes by rotating a disk-shaped valve disc. It has a lightweight, compact structure and relatively low pressure drop. It has the advantage of requiring less force to open and close, and is mainly used for medium flow control.

3. Needle Valve

Needle valves are throttle valves that use an elongated cone-shaped valve plug for precise flow control. Needle valves are used when fine opening control is required and can control fluids with high precision.

4. Ball Valve

This throttling valve opens and closes by rotating a spherical valve plug. It is suitable for smooth on/off control and flow control, and has high shutoff capability. It can be operated with a short rotary stroke, thus enabling quick control.