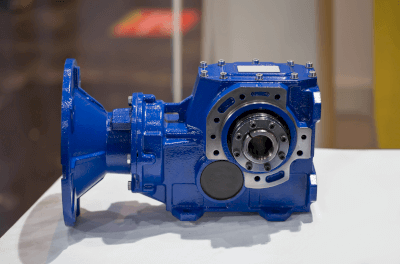

What Is a Helical Reducer?

A helical reducer is a device that reduces the rotational speed of a motor or other device by means of gears.

The teeth of normal gears are engraved parallel to the axial direction of the gear (called spur gears), whereas the teeth of helical gears are engraved at an angle to the direction of the gear’s rotational axis (called helical gears).

Compared to spur gears, helical gears have the advantage of improved gear meshing.

Uses of Helical Reducers

Compared to spur gear reducers, helical reducers are mainly used for final reduction gears in automobiles, because the gears in the reducer mesh more tightly with each other, resulting in higher torque and less noise.

In addition to automobiles, reduction gears are also used to drive screw propellers on ships and propellers on aircraft.

Reduction gears are also indispensable for conveyor belts, assembly robots, elevators, escalators, and other equipment used in factories.

Principle of Helical Reducers

The reason why helical reducers can achieve higher torque and power transmission than ordinary spur gear reducers is that the diagonal teeth improve the meshing ratio.

In addition, since the teeth of helical gears are engraved diagonally, several gear teeth mesh with each other at the same time.

This allows the gears to mesh more smoothly with each other, resulting in a more quieter operation.

Furthermore, helical gears have a higher surface pressure strength than normal spur gears, making them more durable gear reducers.

Although helical gears have many advantages, there are also some points that must be considered.

For example, helical gears generate a thrust force in the direction of the gear’s axis of rotation when the diagonal teeth mesh with each other.

If this thrust force is not taken into account, it can cause wear and rotation problems in gears and reduction gears.

There are several ways to solve this problem, but the most common is to install special bearings to avoid thrust forces.

In addition, the use of double helical gears, in which opposite helical gears are arranged at the same time, counteracts the thrust force on the gear mechanism.