What Is an Electric Crimping Machine?

An electric crimping machine is a device that can crimp wires electrically.

It is an indispensable tool for connecting wires, using the crimping technique to crush the terminals and join the wires together. Electric crimping machines are especially useful for joining wires.

Manual crimping machines also exist, but they are characterized by the fact that it is often difficult to crush thick wires by hand. In comparison, electric crimping machines will not only make it easier to join wires, but they also speed up the crimping process.

Electric crimping machines are excellent equipment for efficient wiring operations. Compared to manual crimping machines, which are labor-intensive, electric crimping machines reduce the burden on the operator and help shorten the work time.

Uses of Electric Crimping Machines

Electric crimping machines are primarily used to join wires together. Specifically, they are used in switchboards and control panels, telecommunications equipment, automobiles, aircraft, railcars, construction equipment, and wire repair and maintenance work. Electric crimping machines also contribute to improved work efficiency, significantly reducing work time and labor compared to manual methods.

In addition to directly soldering wires, they can be joined more firmly by crimping. The stress of the crimp terminal acts on the wire, causing it to return to its original position after being crushed and joined, resulting in a stronger bond.

In addition, a mechanically superior bond can be created. This makes it useful for a variety of equipment that requires a highly secure bond. Especially in the case of thick conductors, it is difficult to crush them by force, requiring an electric crimping machine that can easily crimp them.

Principle of Electric Crimping Machines

Electric crimping machines are powered by an electric motor to join wires and wires together. The basic dynamic principle is that the wires are clamped onto the crimp terminals, and the crimp terminals are crimped onto the wires by applying force with the electric motor. This crimping operation results in a strong bond between the wire and the crimp terminal, and provides a high degree of reliability.

One of the features of electric crimping machines is that they can perform accurate crimping automatically. A constant crimping force can be applied regardless of the wire thickness or the amount of bundled wires. With a manual crimping machine, the force must be adjusted according to the thickness of the wires, whereas with an electric crimping machine, the crimping force can be accurately controlled by an electric motor.

However, it should be noted that electric crimping machines have the disadvantage of being heavier than manual crimping machines. For rechargeable types, the built-in battery makes them considerably heavier. Also, in models that are connected to a power source, the length of the cord may limit the range of use.

Types of Electric Crimping Machines

There are three main types of electric crimping machines: handheld electric crimping machines, bench electric crimping machines, and multi-die head electric crimping machines. In order to select the appropriate electric crimping machine, it is necessary to compare the type, performance, and price according to the situation in which it will be used and the work to be performed.

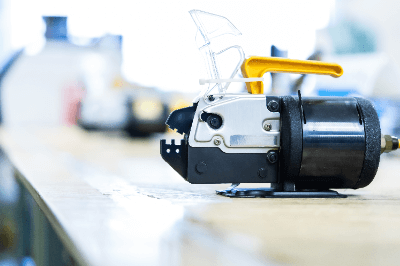

1. Hand-Held Electric Crimping Machine

This hand-held type electric crimping machine is lightweight, easy to use, and portable. The electric type makes crimping work easy to perform. It is used for a wide range of applications, from general wiring work to electrical work, automobiles, aircraft, communication equipment, and construction equipment.

2. Bench Type Electric Crimping Machine

This is a large electric crimping machine and can be fixed to a bench. Suitable for large-size crimping operations, it is mainly used in the aircraft, railroad car, automobile, and heavy electric machinery industries. Since the machine is fixed to a bench, it can maintain a constant crimping force, enabling high-quality crimping operations.

3. Multi Die Head Type Electric Crimping Machine

This type of electric crimping machine has multiple dies and can perform crimping operations for different sizes at the same time. Normally, when done manually, it is necessary to change dies, but a multi-die head type electric crimping machine saves time and effort. It is mainly used in electrical construction and telecommunication equipment.