What Is an Eccentricity Measuring Instrument?

An eccentricity measuring instrument is used to measure the eccentricity, bending, or runout of a shaft or other object.

Eccentricity is defined as the misalignment of the center of a workpiece compared to the center point where it should be. In addition to workpiece eccentricity, runout, bending, concentricity, and coaxiality can also be measured.

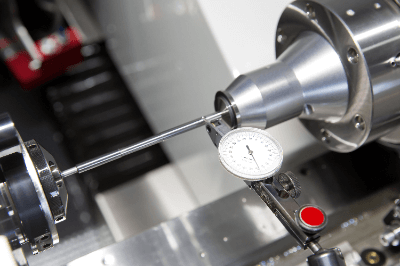

Eccentricity is usually measured using a dial gauge. Center holes machined on both sides of the workpiece are clamped at both centers of the measuring instrument. The dial gage is set at the point to be measured and the workpiece is rotated for measurement.

In addition to the dial gauge method, there are other measurement methods such as reflective and transmissive methods using lasers and optics.

Uses of Eccentricity Measuring Instruments

Eccentricity measuring instruments are used to measure the eccentricity of rotating cutting tools, various arbors, crankshafts, gears, piston heads, etc. Eccentricity measuring instruments are also used to measure the eccentricity of lenses.

Parallelism between the top of the eccentricity measuring instrument table and both centers is assured. The structure is rigid to prevent errors caused by the weight of the workpiece or deviations over time.

The purpose of using eccentricity measuring instruments is usually to check accuracy after machining, such as cutting or grinding. In the case of bending measurement, it is used to check distortion after heat treatment.

By placing the dial gauge on the end face of a workpiece with a multi-stage shaft shape, it is also possible to measure the squareness of the end face with respect to both centers.

Principle of Eccentricity Measuring Instruments

1. Mechanical Measurement

Measurement of Center Standards

The centers of eccentricity measuring instruments are usually made of hardened steel. When used on hard workpieces or for frequent measurements, a carbide center with a carbide brazed tip may be used.

For workpieces with an inside diameter machined instead of a center hole at the edge of the workpiece, an umbrella type center is used. A center with the same bevel angle as the chamfer angle of the bore machining part is required.

A dial gauge is applied to the outer surface of the workpiece and the change in position of the workpiece outer surface is read while the workpiece is rotated slightly. This is the center-based eccentricity measurement.

Measurement of Outer Diameter Standard

Instead of clamping by both centers of eccentricity measuring instruments, the outer diameter of a workpiece is placed on two sets of rollers and supported by two sets of rollers at both ends of the workpiece, for a total of four rollers. Eccentricity can be measured by rotating the workpiece. The measurement value is based on the outside diameter.

There is also an eccentricity measuring instrument that can measure eccentricity by placing one side of the workpiece on a set of two rollers and attaching a roller for clamping to the top of the roller, thereby enabling single-handed measurement. For cylindrical shapes with inside diameter processing, where the coaxiality of the inside diameter with respect to the outside diameter is to be measured, a dial gage can be placed on the inside diameter and rotated to make the measurement.

In either case, the span of the two rollers must be adjusted according to the size of the workpiece diameter.

2. Principle of Non-contact Measurement

Laser Eccentricity Measuring Instrument

Runout of the outer diameter during rotation can be measured. Using a reflective laser displacement meter, a laser is shone on the outer surface of the rotating object and the reflected wave is detected to measure the distance variation. A sampling rate of at least 10 times the rotational speed is required.

Transmission-type laser dimensional measuring instruments can also be used for measurement. The laser is applied to the circumferential direction of the outer surface of the rotating body, and the p-p value of the runout is measured by the receiver. A sampling speed of at least 10 times the rotational speed is required.

In addition, using a transmission-type 2-D laser dimensional measuring instrument, positional variations at multiple points can be measured. Runout of V-grooves and protrusions cut on the circumference can be measured.

Optical Eccentricity Measuring Instrument

This method measures the eccentricity of convex and concave lenses. There are two types: reflective and transmissive. The reflective eccentricity measuring instrument measures the eccentricity between the outer diameter of the lens under test and the spherical center of the lens using the reflective method.

The transmission eccentricity measuring instrument measures the transmission eccentricity of a lens. Transmission eccentricity is the amount by which transmitted light deviates from the optical axis. The optical axis is the line connecting the spherical centers of both sides of the lens.

Other Information on Eccentricity Measuring Instruments

How to Use Eccentricity Measuring Instruments

First, on the table of the eccentricity measuring instrument, set the left and right centers at the desired positions according to the length of the workpiece and lock each of them. One of the left and right centers is designed to move in and out by operating a lever.

By operating this lever, the workpiece is set with the center retracted, and the workpiece is clamped by returning the lever. The force of the spring enables the workpiece to be supported with constant holding force.

The dial gauge is placed on the outer surface of the workpiece, and the workpiece is rotated. The change in the pointer obtained at that time is the eccentricity.