What Is a Sheet Gasket?

Sheet gaskets are sheet-shaped components or materials used in equipment, structures, piping, etc., to prevent internal fluids from leaking out.

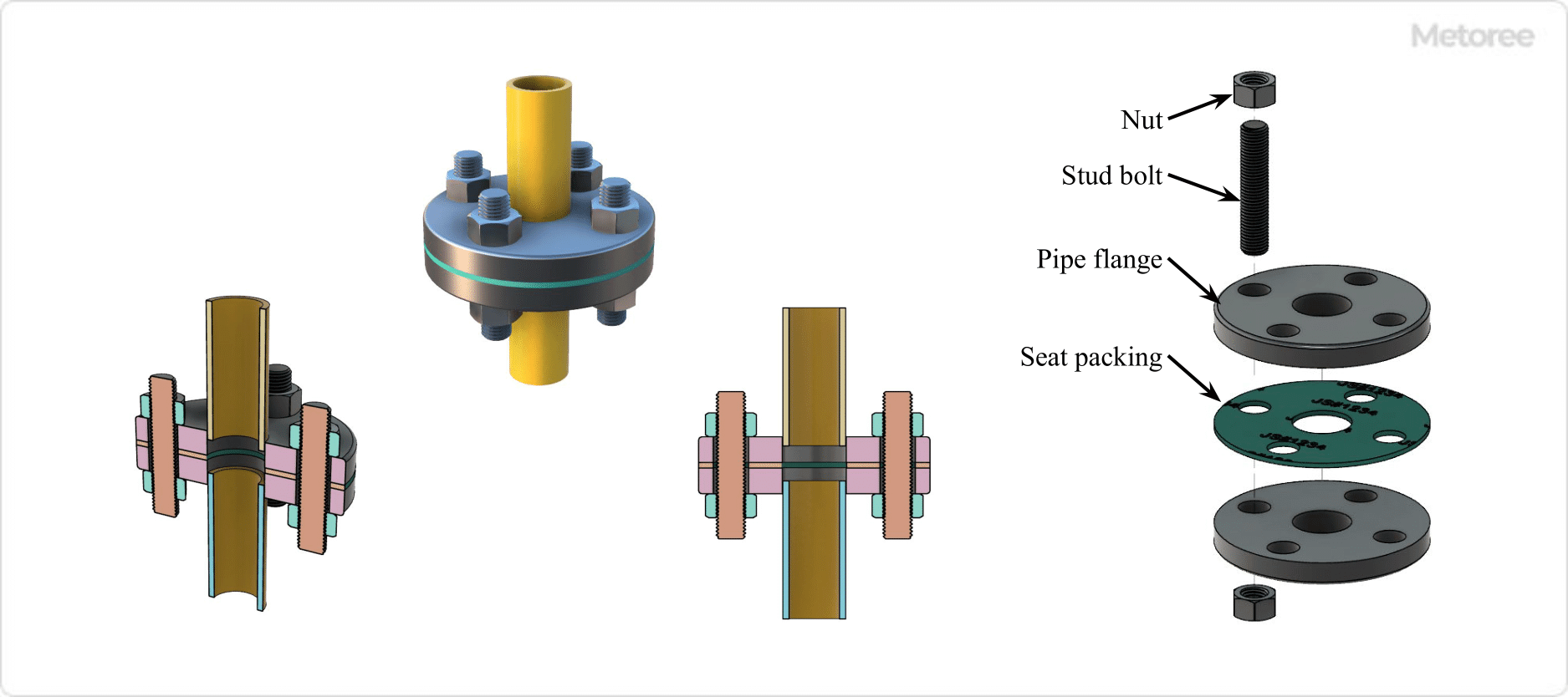

Although gaskets are used for similar purposes, seat packing is a type of sheet gasket among non-metallic gaskets, and although they are called differently, they are basically the same thing. In general, there are gaskets and packing for sealing purposes, and gaskets are mainly used for “motionless” or “immobile” parts.

Gaskets are mainly used for “motionless” or “immobile” parts, whereas packing is mainly used for “moving” or “movable” parts. In this case, however, seat packing, like gasket, is used for “motionless” or “immobile” parts.

Uses of Seat Packing (Sheet Gaskets)

Figure 1. Sheet packing for pipe flange

Seat packing is used to maintain airtightness and sealing. Generally, manufacturers’ products are shipped in large sheets, and processors and users cut or drill the sheets to the required dimensions before use.

Principle of Seat Packings

O-rings made of rubber are well-known as gaskets. O-rings are soft, so when they are tightened and pressurized, their shape changes to increase adhesion, eliminate gaps, and suppress leaks. However, since they are made of rubber, they have drawbacks, such as breakage when over-pressurized, lack of durability, and cannot be used at high temperatures. Seat packing compensates for these disadvantages.

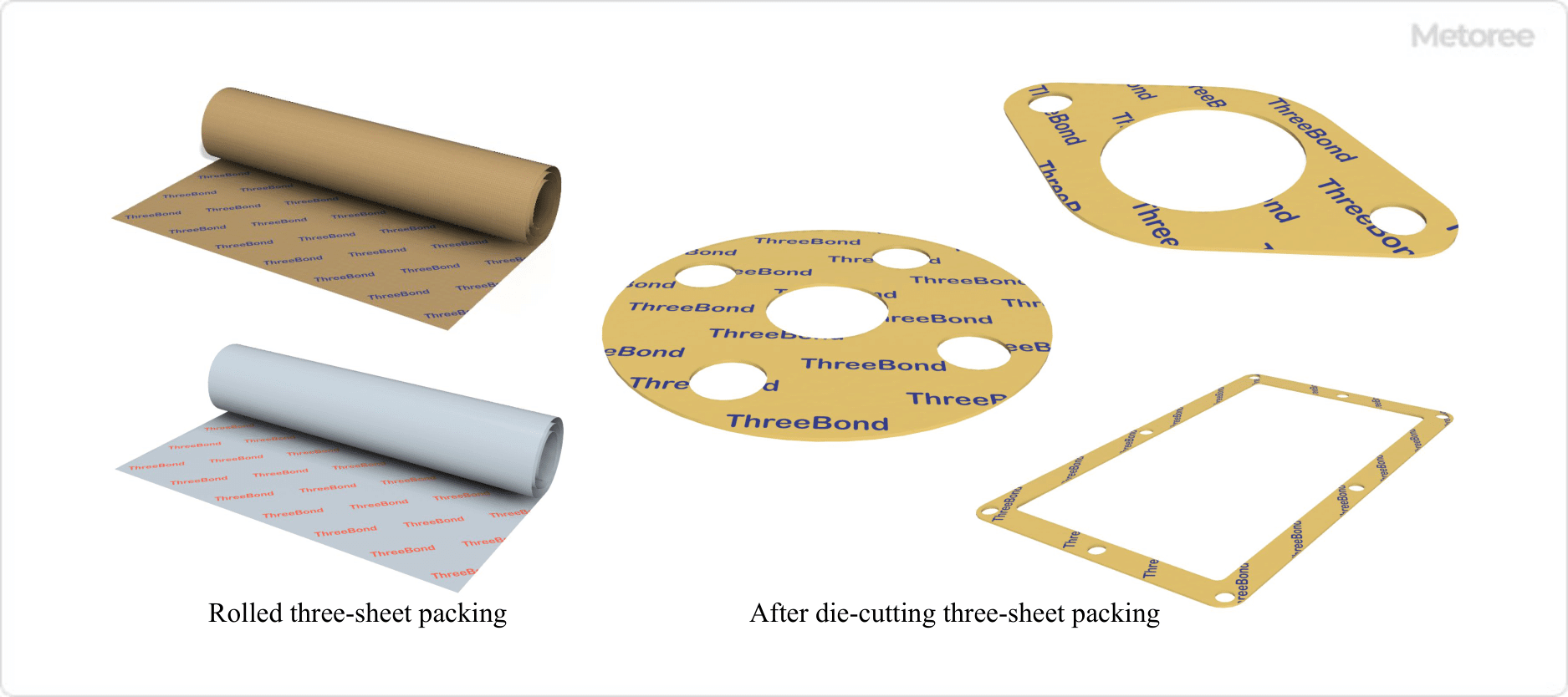

In the three sheet packing, the sheet material is crushed by the pressurization, but the adhesive enhances the adhesion and suppresses leakage. Since the adhesive is used instead of deforming the sheet material, the leak prevention effect is sustained. On the other hand, it is disposable and cannot be reused once used.

In addition, adhesive remains at the joints, so the adhesive must be removed cleanly the next time it is used. Another disadvantage is that if the joints are not parallel but slightly tilted, the adhesive will not stick and seal.

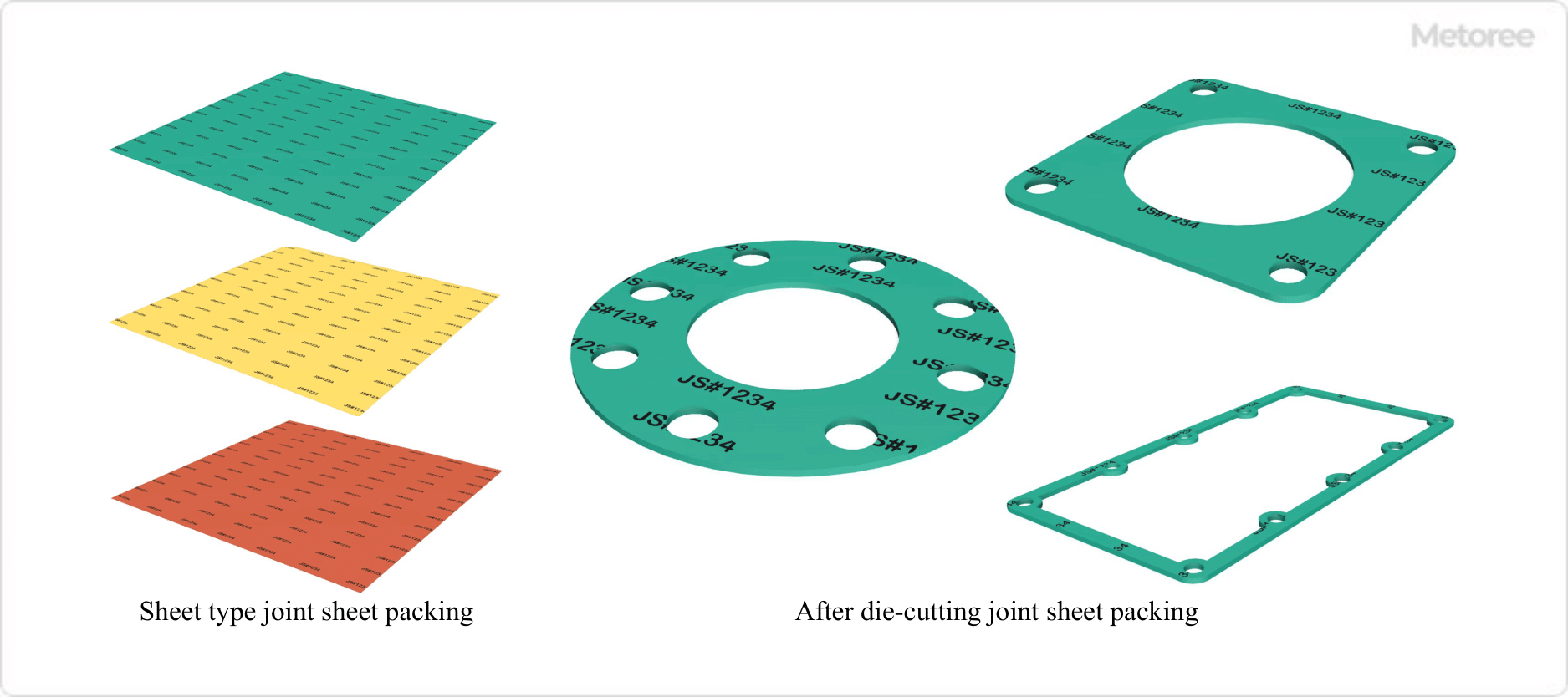

The joint sheet has an intermediate role between the O-ring and the three-sheet. Joint sheets seal by changing shape and have high durability, but since they are also in sheet form, they cannot seal if the joint is even slightly tilted. There is a wide variety of sealants available, and they must be selected appropriately for the situation.

Types of Seat Packing

There are two types of seat packing: three-seat packing and joint sheet.

1. Three-Sheet Packing

Figure 2. Three-sheet packing

Three sheet packing is a sheet-type pack manufactured by ThreeBond. This packing is characterized by the fusion of solid packing and liquid packing. A sheet of high-strength fiber material is impregnated with a special viscous material, and when it is sandwiched between joint surfaces and tightened, the viscous material impregnated inside oozes to the surface and fills the minute uneven gaps on the joint surfaces, thereby enhancing sealing performance.

Therefore, leakage can be prevented with low tightening surface pressure. The viscous material impregnated into the fiber material sheet prevents leakage due to permeation by capillary action. The viscosity impregnation makes it highly flexible and provides a good fit on the joint surface.

Unlike general sheet packing and gaskets, the gap between the joint surfaces is reduced, resulting in less leakage of liquid. In particular, it has excellent resistance to oils. Three-Sheet Packing has a little decrease in thickness after being sandwiched between joint surfaces and tightened, so there is less loosening and good tightening can be maintained.

The operating temperature range and tightening surface pressure are as follows, depending on the model number

- Operating temperature range: -40 to 180 °C

- Tightening surface pressure: 2.94 to 65 MPa (30 to 180 kg/cm2)

Three-Sheet packing is available in rolls of 1,000 x 25,000 mm with thicknesses ranging from 0.1 to 1.15 mm. It is cut and processed according to the shape of the flange, etc.

2. Joint Seat Packing

Figure 3. Joint sheet packing

Joint sheet packing is often referred to as joint sheet gasket, but they are basically the same thing. Joint sheet packing is a packing made by adding heat- and oil-resistant rubber as a binder to fiber sheet material, rolling and vulcanizing it, and forming it into a smooth sheet shape.

Asbestos-containing fibers were used in the past, but after the revision of the law, non-asbestos fibers and carbon fibers are now being used. Joint sheet packing is widely used for flanges and machine joint surfaces because of its versatility and processability.

As an example, the operating temperature range and tightening surface pressure are as follows, although they vary depending on the manufacturer, model number, fluid used, etc.

- Operating temperature range: -50 to 200 °C

- Tightening surface pressure: 20.0 to 0 MPa (204 to 408 kg/cm2)

Joint sheet packing dimensions range from 0.41 to 3.0 mm in thickness and come in large sheets in sizes from 1,270 x 1,270 mm to 3,048 x 3,810 mm. They are cut and processed according to the flange shape and other specifications.