What Is a Steel I-Beam?

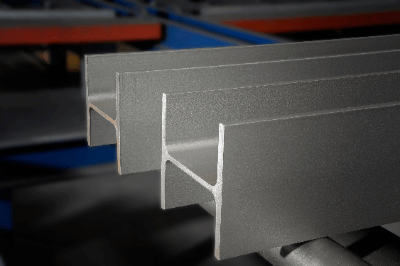

A steel I-beam is a long steel beam with an H-shaped cross-section, mainly used as columns and beams in steel-framed buildings. The manufacturing of steel shapes by hot rolling was first patented in 1849 by a Belgian company.

A steel I-beam is a long steel beam with an H-shaped cross-section, mainly used as columns and beams in steel-framed buildings. The manufacturing of steel shapes by hot rolling was first patented in 1849 by a Belgian company.

Uses of Steel I-Beams

Steel I-beams are favored for their high compression and bending resistance. They are commonly used in:

- Foundation piles for quays, buildings, bridges, etc.

- Structures of high-rise buildings

- Crane girders for overhead cranes

- Steel stairs in industrial settings

There are two main types of steel I-beams: one for structural purposes and another for foundation columns.

Principles of Steel I-Beams

Steel I-beams are made from either rolled structural steel (SS) or welded structural steel (SM), with rolled structural steel (SN) specifically used in building construction since 1994. SS material is typically used for secondary members, SM for welded beams, and SN for large beams in architecture.

Steel I-beams offer high bending resistance per unit weight, which can be increased by thickening the flanges.

Types of Steel I-Beams

- Rolled Steel I-Beams: Formed by rolling iron into an H shape, suitable for mass production.

- Built Steel I-Beams: Made by welding steel plates into an H shape, allowing for custom thickness and dimensions but more expensive than rolling.

- External Constant Steel I-Beams: Feature a constant width from top to bottom, used for beams with large spans.

Manufacturing Process of Steel I-Beams

The hot rolling process involves initially rough rolling a heated steel ingot (bloom) with grooved rolls to form a shape similar to steel I-beams. The material is then rolled into the I-beam shape using a universal rolling mill. Recent advancements allow for easier adjustments in the web height and flange width without changing the rolls. In some cases, the steel ingot process is bypassed, and slabs from the continuous casting method are directly used in rolling.