What Is Structural Steel?

Structural Steel, also known as SS steel, is a type of low-carbon steel.

Structural Steel, also known as SS steel, is a type of low-carbon steel.

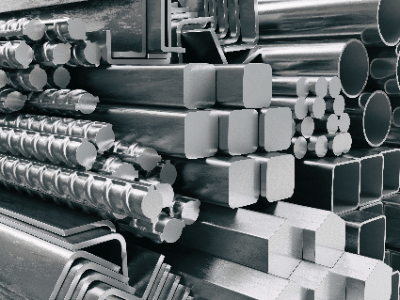

It has the disadvantage of being susceptible to rust, however it is widely used in various fields because it is manufactured in various shapes such as plate, H steel, bar, and mountain steel, and because it is highly versatile.

Uses of Structural Steel

Although there are various types of steel materials, they are used in such a wide range of fields that steel = SS materials. Among steel materials, SS material has good rationality and convenience because of its low defective products and high yield rate.

High tensile strength steel is used for parts that require particular strength, but it is expensive and difficult to process, so inexpensive SS material with medium performance is useful.

Specific applications are as follows:

- Construction and civil engineering products

Bridge supports and beams, building frames and roofs, reinforcing bars for foundations, etc. - Machine tools

Lathes, welding machines, presses, machine parts, etc. - Production equipment

Containers, molds, casting equipment, etc. - Means of transportation

Railroads, ships, vehicles, etc. - Power facilities

Power transmission towers, wind power generators, etc. - Home appliances

Refrigerators, microwave ovens, etc. - Ancillary equipment

Benches, scaffolding, road signs, etc.

Characteristics of Structural Steel

There are no clear standards for impurities contained in low-carbon steel with approximately 0.2% carbon content in SS materials, except that phosphorus and sulfur content is determined to be within 0.05%. In addition, strength increase by heat treatment is not possible when the carbon content is 0.3% or less.

Structural Steel is also used as raw steel, since the emphasis is on tensile strength and yield strength. The effects of thermal brittleness caused by heating are minimal, and can be used for drawing and welding to produce cans.

However, since it does not form an oxide film like copper and aluminum, heated and machined parts are prone to rust, requiring painting or surface treatment. The molten steel is cast directly, and the limed steel is formed, so impurities remain, but the quality can be maintained because the inside is crimped by rolling.

Note that killed steel is deoxidized. By adding additives, gases and impurities are removed and the internal structure is homogenized.

Other Information on Structural Steel

Standard Steel Products of Dimensions

There are standard steel products of various dimensions, such as L-shaped mountain steel, U-shaped groove steel, H steel, and flat steel. Plates are 3.2 mm or thinner, such as cold-rolled steel sheet (SPCC), and similar materials include rolled steel for building construction (SN), rolled steel for welded structures (SM), and carbon steel for machine structural purposes (SC).

Other types of carbon steel include low carbon steel, medium carbon steel and high carbon steel.