What Is a Resist?

A resist is a material used to protect specific areas of a substrate in processes such as etching and soldering. Generally, “photoresist” used in semiconductor processes are simply called “resist”.

A resist is a material used to protect specific areas of a substrate in processes such as etching and soldering. Generally, “photoresist” used in semiconductor processes are simply called “resist”.

When a photoresist absorbs light of a specific wavelength, the chemical structure of the photoresist changes, and its solubility in cleaning and developing solutions also changes. Therefore, after applying resist to a substrate, it is possible to solubilize or insolubilize only a portion of the resist by irradiating light onto the substrate through a mask depicting a circuit pattern.

When the substrate is washed with a developing solution in this state, only the soluble resist is eluted, and only a portion of the substrate is protected by the resist.

There are two types of resist: positive type resist, in which the light-irradiated area dissolves in the developing solution, and negative type resist, in which the light-irradiated area becomes insoluble.

Uses of Resists

Resists are materials that protect specific locations in processes such as etching and soldering. Photoresist, which is a photosensitive agent in the semiconductor process, is often referred to simply as resist. Therefore, this article will also introduce photoresists.

Photoresists change their chemical structure when exposed to light and develop chemical resistance or, conversely, dissolve in a developing solution.

Using this property, photoresists applied on a silicon wafer are irradiated with light through a mask depicting a predetermined pattern and finally washed with a developing solution to create a processed area without resists and a non-processed area protected by resists on the substrate.

Resists are one of the indispensable materials for manufacturing highly integrated and miniaturized semiconductor integrated circuits.

How to Use Resists

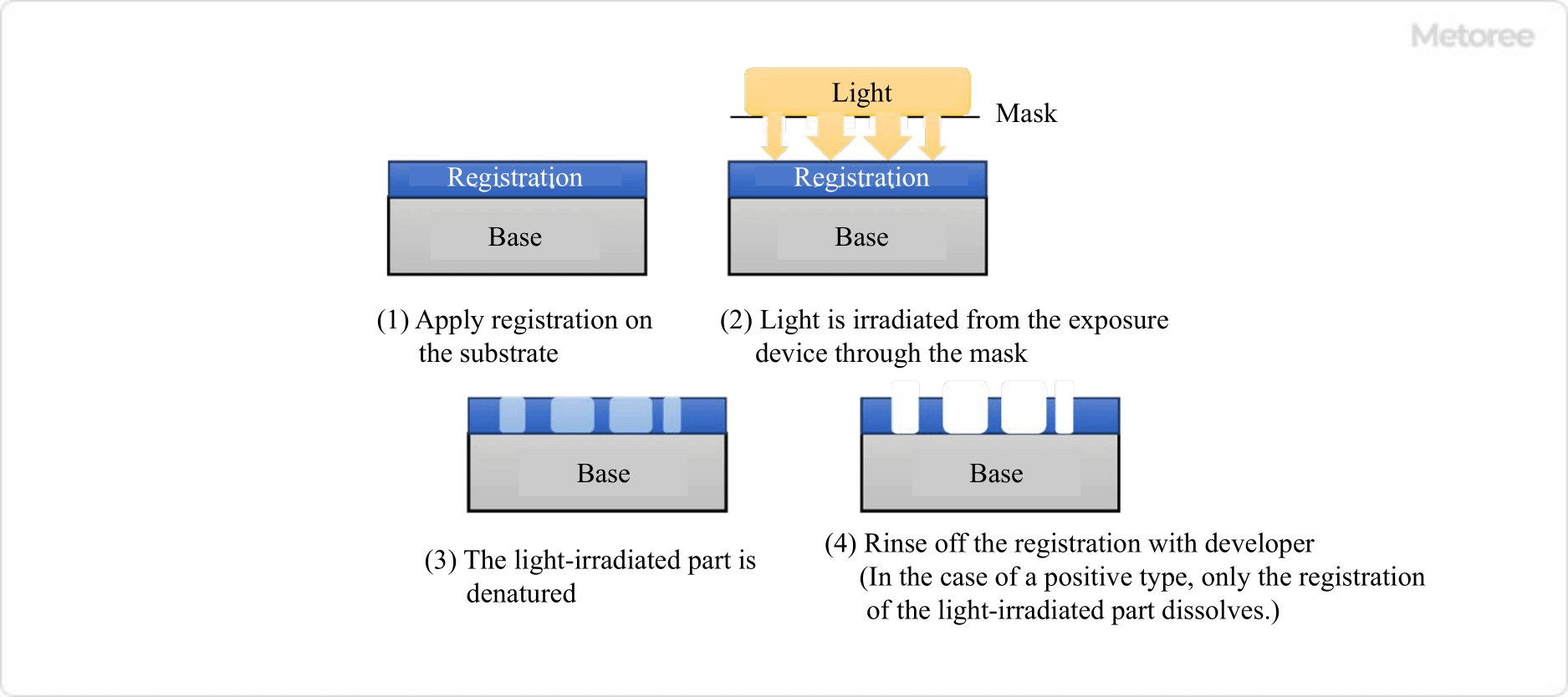

Figure 1. How to use resist

In the semiconductor manufacturing process, silicon wafers are etched to create fine irregularities. Resists are used to selectively protect the substrate during the etching process.

First, resists are uniformly applied on the substrate, and then light is irradiated through a mask that depicts IC circuits on the resists. The chemical structure of the resists at the irradiated area is changed by absorption of light, and the solubility of the resists in the developing solution can be changed depending on whether the resists are irradiated or not. In the case of positive type resists, the light-irradiated area becomes soluble, while in the case of negative type resists, the non-irradiated area becomes soluble.

Thus, by etching with resists selectively remaining on the substrate, it is possible to selectively remove the substrate only in the areas where there are no resists.

After etching, the resists remaining on the substrate are removed and cleaned to complete the substrate patterning.

Resist and LCD

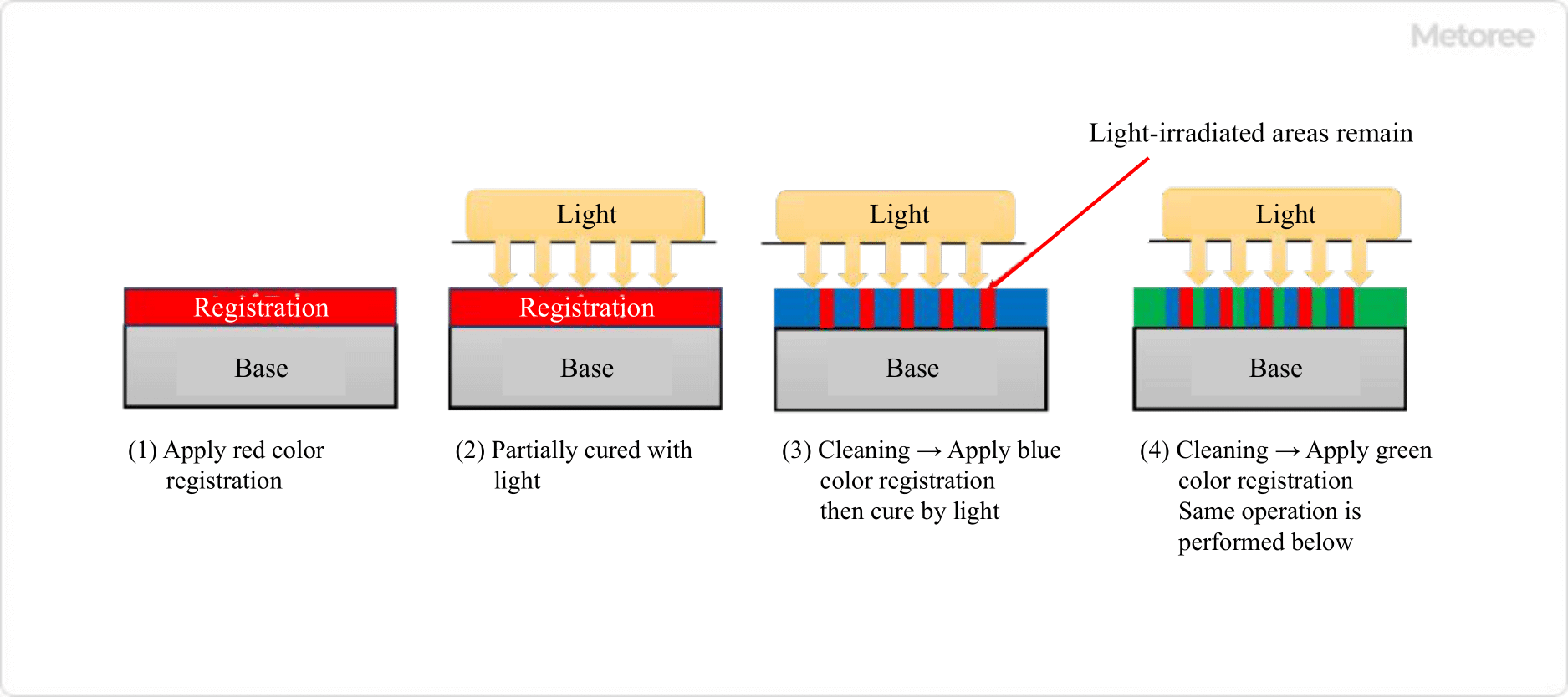

Figure 2. Resist and LCD

Some resists are called color resists, which are inks containing pigments or other color materials. Color resists applied on a glass substrate are cured by irradiating it with light such as ultraviolet light so that the resists are not washed away by the developing solution after light irradiation.

Liquid crystal displays are patterned with the three primary colors of red, green, and blue, and color resists are used here. Red, green, and blue patterns can be formed by first applying red color resists, light-curing only the designated areas, and then washing with a developing solution, followed by the same process for green and blue color resists.

Types of Resists

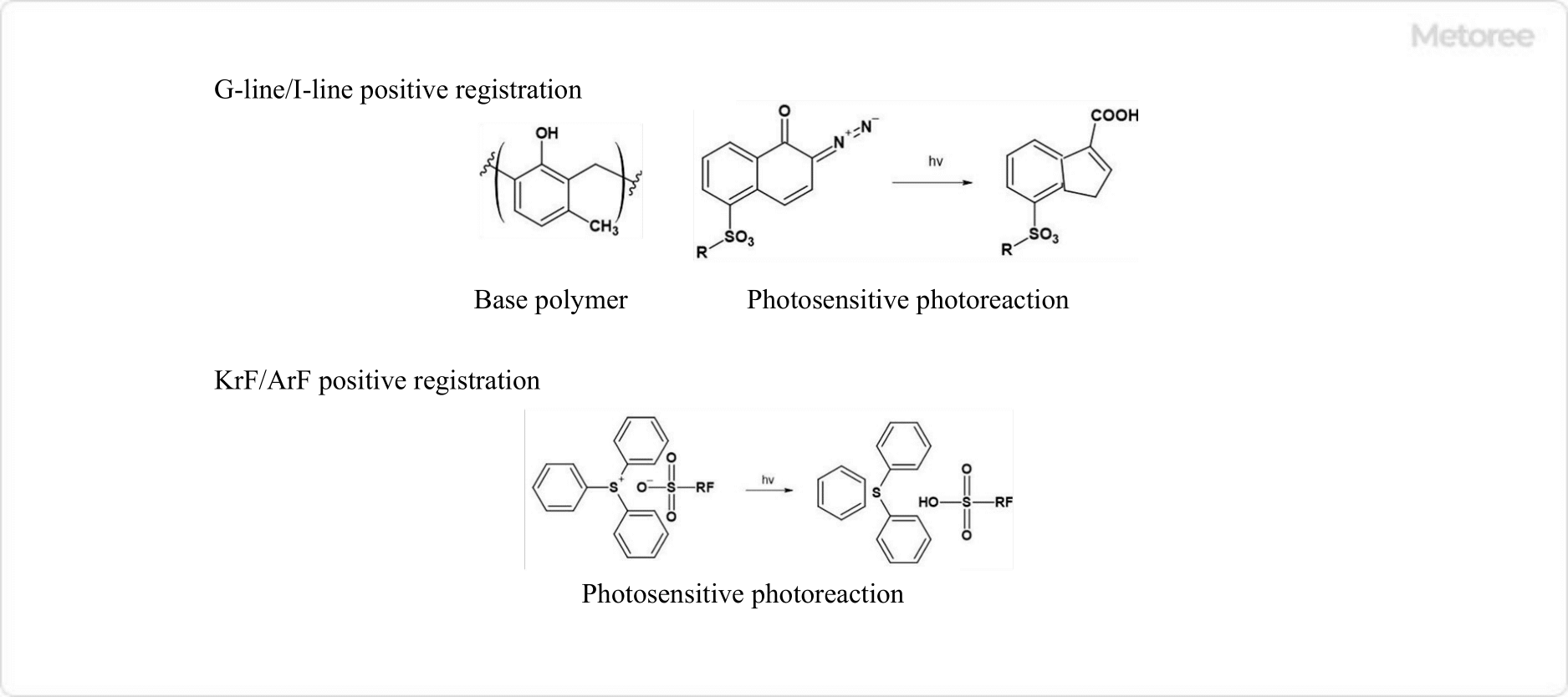

Figure 3. Types of resist

In addition to the classification of positive type and negative type, resist materials can also be classified according to the wavelength of light they absorb.

In the semiconductor manufacturing process, g-line (wavelength: 436 nm), i-line (365 nm), KrF excimer laser (248 nm), and ArF excimer laser (193 nm) are used in lithography equipment, and resists with a structure of absorbing each wavelength are available.

For example, positive photoresists for g- and i-line lasers use a compound consisting of a Novolac resin and 1,2-naphthoquinone diazide sulfonate (NQD) compounds. In this compound, the NQD is hydrophobic and usually insoluble in aqueous alkaline solutions.

However, when irradiated with g- or i-rays, the NQD moiety is decomposed and converted into a hydrophilic compound. As a result, after irradiation, the resists can be dissolved in an alkaline developing solution.

In addition, positive photoresists for KrF lasers use chemically amplified photoresists, in which an acid is generated by the exposure and the catalytic reaction of the acid accelerates the change of the resists at the exposed area.