What Is Linear Rail?

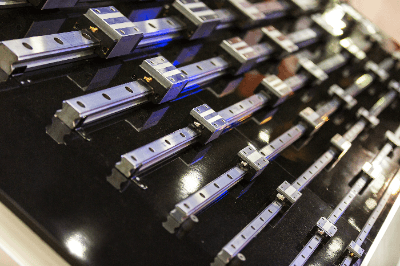

A Linear Rail, also called a Linear Guide, is one of the indispensable machine parts in the drive unit of industrial machines.

A Linear Rail, also called a Linear Guide, is one of the indispensable machine parts in the drive unit of industrial machines.

A typical example is a type in which operating points called carriages with built-in bearing balls or rollers are arranged to allow smooth operation in the direction of the rail. Various types of installation techniques are available and can be seen on doors, guides, and pedestals of various machines.

Uses for Linear Rail

Linear Rails are one of the components of a machine that is used where linear motion is performed frequently.

In addition to machine tools, linear rails can also be found in a variety of other fields, such as robots, aircraft, rolling stock, construction equipment, medical equipment, and automobiles. Linear Rails can be used and arranged in parallel to achieve accurate and stable linear motion.

Principle of Linear Rail

The operational principle involves the carriage moving within the rail, unlike the extension of a desk drawer slide rail, for example.

The length of the rail determines the operating range. The carriage incorporates bearing balls or rollers to minimize the contact points, resulting in smooth operation and reduced deterioration of the machine’s service life due to wear and tear.

To handle heavy loads, rollers are often used instead of carriage-based types. Rollers can be recirculating or non-recirculating. In the non-recirculating design, the distance is limited by the length of the bearings. In addition, the load applied by the machine to the Linear Rail is closely related to the life of the equipment, so its specifications and environment must be carefully considered.

Linear Rail materials are generally V-shaped steel rails or aluminum rails, and there are many types depending on the application. Each company offers a variety of linear rails and linear guides, but in order to provide products that are highly durable and maintenance-free as required by the market, they are devising mechanisms and competing with technology.