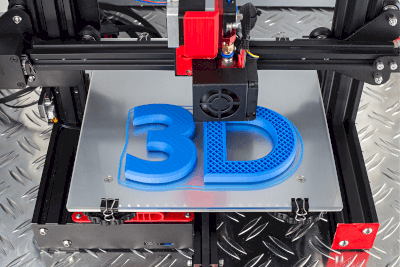

What Is an Industrial 3D Printer?

A 3D printer is a printer that can actually produce a shape designed by 3D CAD.

A 3D printer is a printer that can actually produce a shape designed by 3D CAD.

A 3D model is produced by stacking 2D layers of slices of the designed shape one by one. Originally, this equipment was designed for resin. However, in recent times, 3D printers for metal has been increasing.

There are various types of 3D printers for resins, such as the “optical modeling method,” which hardens liquid resin (UV-curable resin) by irradiating it with UV light, and the “FDM method,” which stacks resin melted by heat.

Applications of Industrial 3D Printers

Industrial 3D printers are often used for prototyping resin products. When mass-producing resin parts by injection molding, etc., the cost of manufacturing molds is enormous. Therefore, 3D printers are used to check if the shape is acceptable before actually manufacturing the molds.

The lamination method allows the production of complex hollow parts. Consequently, 3D printers are also used to create masters for basic jigs and molds. Moreover, recently, finer stacking pitches and improved shape accuracy have led to an increased use of 3D printers for manufacturing final product components.

Principle of Industrial 3D Printer

The variety of materials that industrial 3D printers can be applied to is increasing, and in addition to ABS and acrylic, materials similar to PP, rubber, and various other material properties are now available.

Since support materials are needed to support the parts to be laminated by the 3D printer, it is necessary to shape the parts so that the support materials can be placed. Normally, the support material needs to be removed after printing. However, recently water-soluble support materials have been introduced, which not only increase the degree of freedom of shapes but also improve workability.

On the other hand, problems with 3D printers include the difficulty of producing a flat surface depending on the angle at which the layers are stacked and the long processing time (one day for even a small part).

However, access to 3D printers has increased due to a reduction in their prices. Since the shapes that 3D printers are good at processing and the accuracy differs depending on the modeling method, it is necessary to select the modeling method that best suits the intended use. In addition, it should be noted that modeling may require post-processing (for example, UV irradiation is required in the post-processing stage to completely harden a UV-cured photoengraving object).