What Is a Compact Vacuum Pump?

A compact vacuum pump is a small pump that evacuates air from a sealed container to create a vacuum inside.

Compact vacuum pumps are usually capable of pumping air at a rate of about 200 l/min and achieving a pressure of 0.1 Pa to 10 Pa. They are also used as roughing pumps to obtain a high vacuum environment and are often used in various analytical and scientific instruments that can be operated under low vacuum conditions.

There are various types, such as oil rotary pumps, dry pumps, and diaphragm pumps, which can be selected according to the principle and conditions of use.

Uses of Compact Vacuum Pumps

Compact vacuum pumps are used in analytical and experimental equipment that require a vacuum of about 0.1 Pa or an even higher vacuum environment. For example, compact vacuum pumps are ideal for electron microscopes, X-ray analysis, mass spectrometers, and gas chromatography, which require a vacuum environment.

In semiconductor manufacturing, a vacuum environment is required to form thin films by sputtering, vacuum evaporation, or chemical vapor deposition (CVD). Compact vacuum pumps are also used in food processing for vacuum packaging and vacuum packing.

Principle of Compact Vacuum Pumps

Compact vacuum pumps are classified according to the pumping method, pressure range, and whether oil is used.

1. Pumping Method

Vacuum pumps can be classified by the pumping method into two types: gas transport vacuum pumps and gas sump vacuum pumps. Gas-transporting vacuum pumps transport air from the intake side to the exhaust side.

A gas-accumulating vacuum pump accumulates the air to be exhausted inside the pump and then exhausts the accumulated air with another vacuum pump.

2. Pressure Range

It is impossible for a single vacuum pump to cover the range from atmospheric pressure to high vacuum. Normally, an auxiliary pump or a roughing pump is used in addition to the main pump for high vacuum.

3. Dry/Wet

There are two types of vacuum pumps: dry vacuum pumps, which do not use oil, and wet vacuum pumps, which do. The vacuum area created by oil-using pumps contains oil vapor and water vapor generated by the pump itself.

Dry vacuum pumps are especially necessary in the semiconductor manufacturing process, which requires fine control. Dry types are also used in the manufacture of food products and pharmaceuticals, where oil is not desired.

Types of Compact Vacuum Pumps

1. Oil-Sealed Rotary Vacuum Pump

Among various types of vacuum pumps, oil-sealed rotary vacuum pumps are the most commonly used in terms of displacement volume, achievable pressure, and price. There are many types of this type, depending on the pump type, and they are called rotary types.

Oil functions to lubricate the bearings and to improve sealing in the cylinder. Rotary-type oil rotary vacuum pumps are available in rotary-blade, cam, and oscillating piston types. 0.1 Pa medium vacuum can be easily obtained with these pumps.

Rotary Blade Oil-sealed Rotary Vacuum Pumps

The rotor-blade type has vanes attached to a rotor built into the inner cylinder. Gas in the small chambers divided by the vanes is discharged as the rotor rotates, thereby reducing pressure.

Cam Type Oil-sealed Rotary Vacuum Pump

In the cam type, a portion of the eccentric rotor installed in the center of the cylindrical stator rotates in contact with the stator. Gas in the space between the stator and rotor is discharged to reduce pressure.

Oscillating Piston Type Oil-sealed Rotary Vacuum Pump

In the oscillating piston type, the rotation of the eccentric rotor causes the piston to move up and down. Air inside the cylinder is compressed and discharged by the piston to reduce pressure.

2. Dry Pump

Dry pumps are non-contact, clean vacuum pumps that do not use oil or liquids. There are many types depending on the pump type.

Roots Type Dry Vacuum Pump

This pump uses a Roots type rotor. They do not require cooling water and are highly convenient.

Scroll Type Dry Vacuum Pump

The scroll rotates to create a vacuum by compressing and discharging air from the outside to the inside. It is compact and has the advantages of high vacuum, low vibration, low noise, and energy saving.

Claw Type Dry Vacuum Pump

Vacuum is created by two claw-shaped rotors rotating in opposite directions.

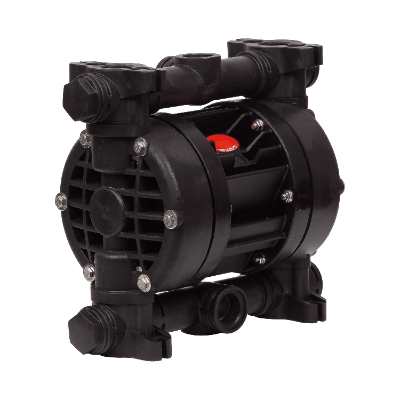

Diaphragm Type Dry Vacuum Pump

A piston called a pump shaft moves back and forth to raise and lower a diaphragm, which sucks in and discharges air.

Others

Rotating blade type and oscillating piston type are also available. These vacuum pumps are similar in structure to oil rotary pumps.