What Is a Honing Machine?

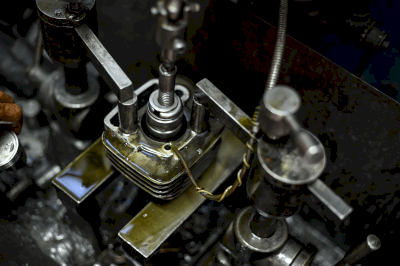

A honing machine is one of the machines used for surface finishing. The machine rotates while crushing the inner surface of a cylindrical workpiece with multiple grinding wheels attached in the shape of sticks to finish the inner surface.

Since it is not possible to cut a large number of pieces at once, honing machines are generally used for final finishing after cylindrical cutting with boring machines or other machines.

Although honing machines are similar to internal grinding machines, they are capable of machining more precise hole accuracy, roundness, and higher surface roughness.

Uses of Honing Machines

Honing machines are often used for machining the internal surfaces of engine cylinders, which require extremely high precision in order to achieve the final finish on cylindrical workpieces.

The surface roughness is almost mirror finish, but if you look closely, you can see small scratches in the form of crossed lines, which adhere to the engine oil and keep the oil film to protect the cylinder from friction with the piston, so it is ideal for machining engine cylinders that constantly circulate high pressure oil.

Principle of Honing Machines

Most honing machines are vertical machines, and the bore is machined by the up-and-down motion of a grinding wheel attached to the stick-shaped tip.

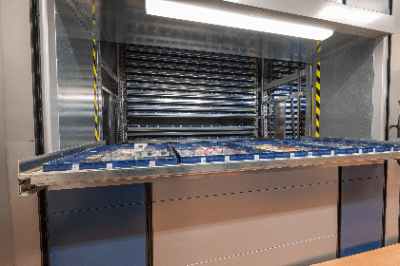

Other types of honing machines include the parallel flat honing machine, which sandwiches the workpiece between two disk-shaped grinding wheels and uses a reciprocating motion to align multiple workpieces to a uniform height; the CNC multi-axis honing machine, which performs the entire process automatically, eliminating the need to use separate grinding wheels for intermediate and final finishing operations; and the honing machine with a water and abrasive grain mixture sprayed onto the workpiece. Liquid honing, in which a mixture of water and abrasive grains is sprayed onto the workpiece to create a matte finish on the surface, and other types of honing.

Both of these processes do not apply heat or load to the workpiece as in the cutting process, and they do not affect the accuracy of heat-sensitive workpieces. However, the honing process is based on the shape created by the grinding process prior to honing, so the quality of the previous process is important to achieve high accuracy.

In addition, honing cannot exceed the outside diameter of the stick on which the grinding wheels are mounted, because the multiple grinding wheels are all attached to each other in close contact. Therefore, it is necessary to prepare separate sticks for the inner diameter of each workpiece and separate grinding wheels to be attached to the sticks, which has the disadvantage of being very costly.

Honing Process Cross Hatch

A fine mesh of scratches created by honing is called a cross hatch.

Cross-hatches are formed gradually by the repetitive back-and-forth motion of a rotating horn that creates a fine mesh of scratches at different angles when moving downward and upward.

First, a coarse grindstone is used in roughing to create a large-angle mesh at a relatively slow rotation speed, followed by finishing with a fine grindstone at a higher rotation speed to create small-angle scratches, and finally cross-hatching is formed with an angle of about 20° to 60°.

By creating cross hatches in this way, oil can enter the grooves of the cross hatches where metals slide against each other, preventing the oil film from running out.

Examples of this process include engine parts such as cylinders, rocker arms, and connecting rods.

Difference Between Honing and Polishing

Honing and polishing (internal grinding) can both be used for hole drilling with high precision as finishing processes, but the machining methods are different.

Honing involves pressing multiple cylindrically mounted grinding wheels together in a reciprocating motion, whereas internal grinding involves placing only one point of the grinding wheel on the workpiece and rotating the workpiece and grinding wheel together.

Honing can produce a higher roundness and surface roughness than internal grinding, but it has the disadvantage that it cannot be corrected because it follows the hole drilled in the previous process, whereas internal grinding can be corrected to some extent and is determined by the accuracy of the centering process.

In addition, cross hatches can only be produced by honing, which cannot be done with internal grinding.

Incidentally, one of the hole finishing tools often used on milling machines is a reamer, which is also used for hole finishing, but has the disadvantage that it is more difficult to handle hardened, high-hardness steel than grinding.