What Is a Compression Terminal Lug?

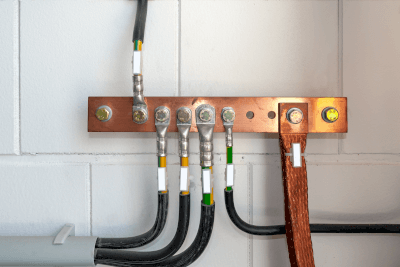

A compression terminal lug is a terminal lug attached to the end of a wire using a special tool, and is used to electrically connect a wire to a terminal block, etc

Crimp terminals are similar to compression terminal lugs. Both are used because they can connect wire to terminal block without soldering, thus eliminating the need for soldering skills, and also because they are relatively easy to remove compared to soldering.

Compression terminal lugs come in a variety of shapes and sizes, depending on the thickness of the wire to be connected and the terminal block to which they are connected.

Uses for Compression Terminal Lugs

Compression terminals, like crimp terminals, are used to secure wires to terminal lugs or to firmly connect wires to each other. In both cases, they are used to ensure that the wires are securely joined so that they will not come loose.

Terminals are connected using a tool called a compression terminal lug. If the wrong tool is used, the proper compression force will not be applied and the compression terminal lug and wire will only be imperfectly connected.

Note that an incomplete connection may result in the wire disconnecting due to an unforeseen accident such as the wire being pulled.

Principle of Compression Terminal Lugs

In the case of crimp terminals, a part of the vinyl coating is removed from the tip of the wire, which is then threaded through a hole provided in the crimp terminal, and connected to the wire by applying force to one point on the crimp terminal where the wire is inserted using a special metal fitting.

On the other hand, in the case of compression terminal lugs, the tip of the wire, which has been stripped of its coating, is inserted into the hole provided in the compression terminal lug, but force is applied not to a single point of the compression terminal lug in which the wire is inserted, but to the entire wire insertion area to connect the two.

Therefore, the compression terminal lug has a stronger bonding force between the wire and the terminal lug than the crimp terminal lug.

Unlike joining wires by heating, such as soldering or welding, joining wires by compression does not affect the environment. Furthermore, mechanical bonding is resistant to deterioration and is stronger than bonding with insulation tape or other external factors such as wire tension.

When a wire is compressed, the sheath must be properly stripped. If the portion of the wire where the sheath is stripped is short compared to the compressed portion, the compression will be incomplete, and the wire may come loose. Conversely, if too much of the sheath is stripped off, it may cause leakage or fire.