What Is a Pneumatic Artificial Muscle?

Soft actuators, also known as pneumatic artificial muscles, generate force by deforming a flexible material with external energy. These artificial muscles are poised to extend their applications beyond industrial robotics, where traditional actuators have predominantly been used.

Pneumatic artificial muscles vary based on the type of energy input. Some, like polymer actuators, deform by applying electrical, magnetic, or chemical energy, while others, specifically pneumatic artificial muscles, deform by fluid pressure such as air or hydraulic pressure. This discussion focuses on pneumatic artificial muscles that contract when air pressure is applied.

Pneumatic Artificial Muscles

Pneumatic artificial muscles are tubular devices that contract upon the application of air pressure. Utilizing compressible air, they exhibit moderate springiness and are characterized by high output relative to their weight.

A typical example is the McKibben pneumatic artificial muscle, which has been extensively studied and is gaining renewed interest with the development of wearable devices and soft robots. These muscles consist of a rubber tube with a braid around its circumference. Radial expansion of the tube alters the angle of the mesh, creating axial contraction force.

In McKibben-type muscles, the pressure typically ranges from 100 to 700 kPa(G), with the contraction amount and maximum force increasing with applied pressure. The contraction can be up to 20% of the initial length, with the force controlled by the muscle’s diameter and applied pressure.

Applications of Pneumatic Artificial Muscles

Lightweight and capable of generating high output, pneumatic artificial muscles are expected to find use in wearable devices and soft robots. Their application as assistive force in suits is increasing. However, these muscles tend to lose flexibility at higher pressures, posing a challenge in achieving both high output and flexibility, especially in wearable devices where muscle movement needs to synchronize with human body movements.

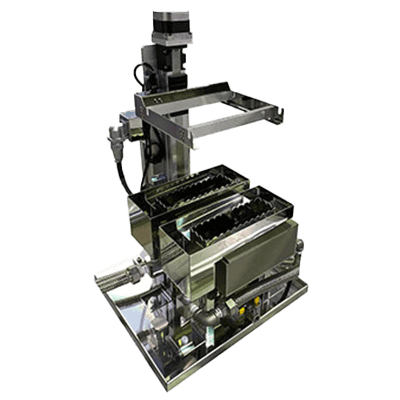

Recently, the advent of thin pneumatic artificial muscles has made it possible to obtain significant contractile force without sacrificing flexibility by using them in parallel. Additionally, dedicated controllers for automatic control of pneumatic artificial muscles are now available, accelerating efforts towards their full-scale social implementation.