Qu’est-ce qu’un réchauffeur ?

Un réchauffeur est un terme utilisé pour décrire tous les appareils qui génèrent de la chaleur.

Le type d’appareil qui brûle du combustible pour générer une chaleur rayonnante est peu coûteux et est donc largement utilisé dans les appareils ménagers. Il s’agit également d’un équipement essentiel dans l’industrie, pour la transformation et l’assemblage.

Utilisations des réchauffeurs

Les réchauffeurs sont des appareils utilisés dans un large éventail d’utilisations, des appareils ménagers à l’industrie. Voici quelques exemples :

1. Réchauffeurs de panneaux

Dans les régions froides où les températures sont inférieures à zéro, il n’est pas rare que les composants internes des panneaux de contrôle se condensent ou gèlent. Il peut s’avérer nécessaire de maintenir la température interne constante à l’aide de réchauffeurs de panneaux. Les réchauffeurs sont également synonymes et sont souvent installés à l’intérieur des générateurs et autres équipements.

2. Réchauffeurs de plomberie

Ces réchauffeurs sont utilisés pour empêcher le gel des conduites d’eau, etc. Ils sont également appelés réchauffeurs antigel, ceintures antigel ou réchauffeurs de trace. Les réchauffeurs à bande et à courroie sont principalement utilisés.

3. Réchauffeurs industriels

Ces réchauffeurs sont utilisés pour chauffer des matières premières et des produits à des fins industrielles. Les principes utilisés varient et les réchauffeurs sans contact tels que le chauffage par induction et le chauffage diélectrique sont également utilisés.

Les utilisations sont variées et comprennent les réchauffeurs de roulements pour l’enlèvement des roulements dans les équipements rotatifs. Les extrudeuses et les machines de moulage utilisent des réchauffeurs de coulée, par exemple.

4. Réchauffeurs domestiques

Il s’agit de réchauffeurs utilisés pour le chauffage et à d’autres fins dans la maison. Les climatiseurs et les aérothermes en sont des exemples typiques. Les appareils de chauffage en céramique sont parfois utilisés. Les fours à micro-ondes et les grille-pain pour la cuisine sont également des types de réchauffeurs.

Principe des réchauffeurs

Les réchauffeurs chauffent des objets selon différents principes. Voici quelques exemples de principes de chauffage des réchauffeurs :

1. Chauffage par résistance

Le chauffage par résistance est une méthode qui consiste à faire passer un courant électrique à travers une résistance pour générer de la chaleur par effet Joule. Un fil de nichrome est utilisé comme élément chauffant. L’élément chauffant est placé dans une gaine métallique, telle qu’un tuyau, entre laquelle se trouve souvent un isolant.

2. Chauffage par induction

Cette méthode permet de chauffer un objet en générant et en modifiant le flux magnétique au moyen d’une bobine, générant ainsi des courants de Foucault. Parmi les utilisations typiques, l’on peut citer les réchauffeurs à induction pour la cuisine. Le chauffage sans contact est possible, mais l’objet à chauffer est principalement constitué de matériaux conducteurs.

3. Chauffage diélectrique

Il s’agit d’une méthode de chauffage par application d’une tension à haute fréquence, qui agite les molécules et génère de la chaleur par friction. Les fours à micro-ondes sont un exemple d’utilisation du chauffage diélectrique. Le chauffage sans contact est possible et est utilisé pour chauffer des matériaux non conducteurs.

4. Pompe à chaleur

Méthode de chauffage par échange de chaleur avec une source de chaleur. Les climatiseurs et les chauffe-eau en sont des exemples typiques. Les climatiseurs, par exemple, ajoutent de la chaleur à une pièce en chauffant l’échangeur de chaleur intérieur avec la chaleur de condensation du réfrigérant comprimé.

Types de réchauffeurs

Il existe différents types de réchauffeurs, classés en fonction de la cause de la production de chaleur et de l’application. Ils sont également classés en fonction de la méthode de conduction de la chaleur. Les méthodes de chauffage basées sur la résistance comprennent la convection, la conduction et le rayonnement.

1. Réchauffeurs à convection

Cette méthode consiste à chauffer l’air directement et à le faire circuler. Elle présente certains inconvénients, tels que l’assèchement et l’empoussièrement de l’air chaud. Elle se caractérise toutefois par une chaleur immédiate. Il existe des réchauffeurs à ventilateur à huile et des réchauffeurs à ventilateur en céramique.

2. Réchauffeurs par conduction

Cette méthode transfère la chaleur par contact direct. Seule la zone de contact peut être réchauffée. Elle se caractérise par une consommation d’énergie plus faible que la méthode de convection. Des tapis chauds et des couvertures électriques sont disponibles.

3. Réchauffeurs par rayonnement

Cette méthode chauffe en émettant des rayons infrarouges et de la chaleur, qui sont des ondes électromagnétiques. Elle se caractérise par une chaleur qui provient de l’air et est silencieuse. Il existe des réchauffeurs à charbon et des réchauffeurs à huile.

Autres informations sur les réchauffeurs

Technologie d’économie d’énergie pour les réchauffeurs

Il est possible d’économiser de l’énergie en contrôlant la consommation d’énergie des réchauffeurs et en les utilisant efficacement. En général, les techniques d’économie d’énergie consistent à utiliser des plaques d’isolation thermique et des matériaux d’isolation thermique pour maintenir la chaleur à l’extérieur. Dans certains cas, le contrôle de la température au moyen d’un contrôle de la tension, par exemple, peut contribuer aux économies d’énergie.

Un contrôle avancé de la température contribue également à améliorer les conditions de travail et la précision du traitement des produits. Si la cible chauffée est un liquide tel que l’eau ou l’huile, le contrôle de la température est nécessaire en fonction des caractéristiques du liquide et de la température cible. Lors du chauffage de solides, le contrôle de la température est un facteur de qualité important.

PC steel wire is a high-strength wire used in prestressed concrete to enhance the tension properties of concrete, which is typically weak in tension. By applying compressive force during manufacturing, it significantly increases the structure’s strength, clamping concrete at high stresses of about 80% of the yield point.

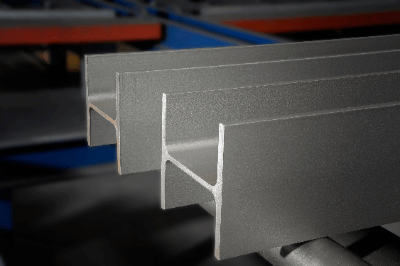

PC steel wire is a high-strength wire used in prestressed concrete to enhance the tension properties of concrete, which is typically weak in tension. By applying compressive force during manufacturing, it significantly increases the structure’s strength, clamping concrete at high stresses of about 80% of the yield point. A steel I-beam is a long steel beam with an H-shaped cross-section, mainly used as columns and beams in steel-framed buildings. The manufacturing of

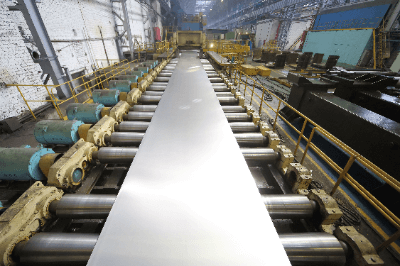

A steel I-beam is a long steel beam with an H-shaped cross-section, mainly used as columns and beams in steel-framed buildings. The manufacturing of  Rolled structural steel, commonly designated as SM400B or SM490C, is a type of

Rolled structural steel, commonly designated as SM400B or SM490C, is a type of  Carbon steel tubes are

Carbon steel tubes are