What Is Rolled Steel?

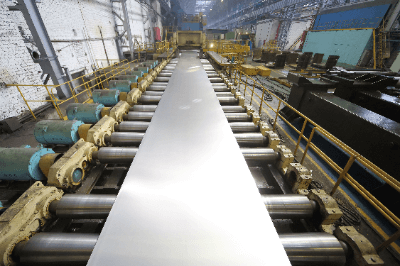

Rolled steel is a steel material formed into sheets through a rolling process involving multiple rolls. It’s cost-effective and well-suited for bending, pressing, and sheet metal working, often used in exteriors and coverings where mechanical strength is not a primary requirement.

Rolled steel is a steel material formed into sheets through a rolling process involving multiple rolls. It’s cost-effective and well-suited for bending, pressing, and sheet metal working, often used in exteriors and coverings where mechanical strength is not a primary requirement.

Rolled steel is categorized into hot rolled steel (SPHC) and cold rolled steel (SPCC), based on the temperature at which it’s rolled.

Uses of Rolled Steel

Rolled steel varies in application, including general structure (SS), building structure (SN), and welded structure (SM) types. It’s commonly used in building structures, particularly in main columns, beams, and welded components due to its high plastic deformation capacity and excellent weldability.

Characteristics of Rolled Steel

Hot-rolled steel, made by heating and rolling the metal at high temperatures (1800 to 2100°F), offers benefits like easier rolling and stronger crystal structures. However, it may have downsides like oxide film formation and loss of dimensional accuracy.

Cold-rolled steel, processed at room temperature, is known for its smooth surface and high dimensional accuracy but requires more force for processing and may undergo work hardening.

Additionally, “warm rolling” is a lesser-known method that serves as an intermediate process between cold and hot rolling.