What Is a Branch Cable?

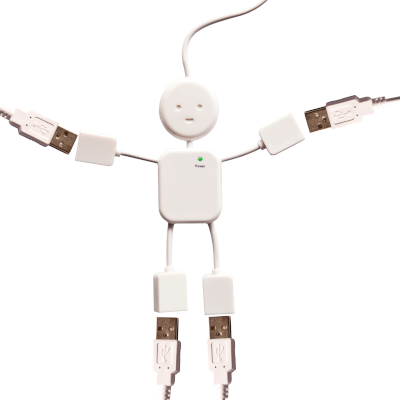

A branch cable is a specialized cable used to distribute various types of wires. For power supplies, branch cables come with sockets or outlets. For lighting, they feature sockets corresponding to the number of branches. There are also specific branch cables for monitors, displays, computers, solar cells, headphones, and microphones.

A branch cable is a specialized cable used to distribute various types of wires. For power supplies, branch cables come with sockets or outlets. For lighting, they feature sockets corresponding to the number of branches. There are also specific branch cables for monitors, displays, computers, solar cells, headphones, and microphones.

With various plug shapes and configurations available, it’s important to select a branch cable that matches your specific needs. Options include varying lengths between cables and the number of branches.

Uses of Branch Cables

Branch cables are primarily used for branching electrical cables in different applications. Waterproof versions are suitable for outdoor use, such as connecting power to road construction indicator lights. In lighting, they can be connected to multiple fixtures, with a choice of length and cable shape depending on the number of fixtures. These cables are also helpful for synchronizing multiple electronic devices, such as PCs and monitors.

Principle of Branch Cables

Branch cables typically consist of a single wire that divides into multiple branches. These wires can be three-phase or two-phase, with color-coded wires for easy identification. Each branch is secured with a sleeve and the entire cable is insulated for protection.

For solar panels, branch cables enable parallel connections, but it’s crucial to adhere to the rated voltage and current specifications. For electronic devices, such as computers, there are various branching connectors for monitors, fans, and earphones to control multiple devices simultaneously.

Earphone or headset branch cables, for example, can connect two 4-pole terminals of smartphones or tablets to a PC’s stereo terminals, useful for audio recording. Connectors are available in configurations like one female to two male branches, one male to two female branches, and all-male or all-female designs.

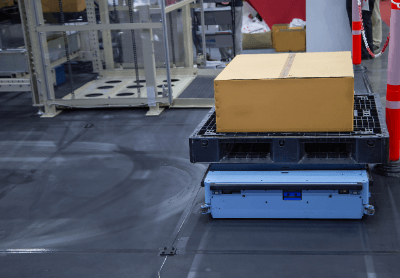

A power roller conveyor is a system where multiple thick rollers are aligned to transport loads by rolling them. It is typically used in factories and logistics for line transportation of heavy-load products. The ideal products for transport are those with a flat bottom and evenly distributed weight.

A power roller conveyor is a system where multiple thick rollers are aligned to transport loads by rolling them. It is typically used in factories and logistics for line transportation of heavy-load products. The ideal products for transport are those with a flat bottom and evenly distributed weight. Battery-powered pumps, operating on batteries, are generally compact. They are used in various settings, particularly where there is no access to a power source.

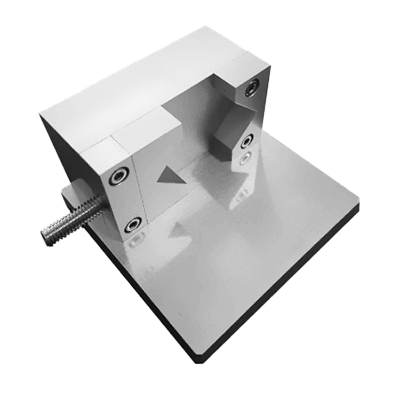

Battery-powered pumps, operating on batteries, are generally compact. They are used in various settings, particularly where there is no access to a power source. Wood drills are specialized tools for drilling screw holes, dowel holes, and through holes in wood. They provide a stronger joint compared to nails and are essential for secure wood assembly. Wood drills come in hand-held and stationary types, both of which are electric, with the hand-held type being more suitable for on-site drilling and the stationary type for factory use.

Wood drills are specialized tools for drilling screw holes, dowel holes, and through holes in wood. They provide a stronger joint compared to nails and are essential for secure wood assembly. Wood drills come in hand-held and stationary types, both of which are electric, with the hand-held type being more suitable for on-site drilling and the stationary type for factory use. A single faucet, commonly found in various settings, allows for water flow adjustment by

A single faucet, commonly found in various settings, allows for water flow adjustment by

Mini pliers are tools used for cutting thin metals, resins, and other relatively small, hard materials.

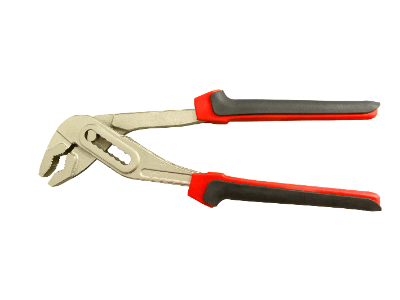

Mini pliers are tools used for cutting thin metals, resins, and other relatively small, hard materials. Water pump pliers are versatile tools used for gripping pipes, nuts,

Water pump pliers are versatile tools used for gripping pipes, nuts,