What Is an FPGA Board?

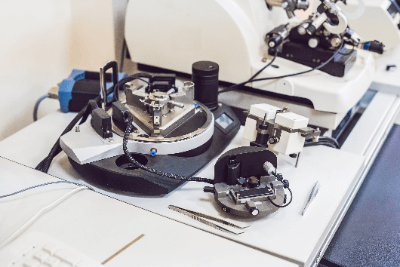

An FPGA board, also known as an FPGA evaluation board or FPGA development board, is a board equipped with an FPGA (Field Programmable Gate Array) and peripheral components. It is primarily used in the initial stages of FPGA development or for educational purposes related to FPGA development.

FPGAs are typically mounted on dedicated boards tailored to specific product specifications. However, since these dedicated boards take time to develop, FPGA boards are often used for early-stage evaluation of FPGAs in product development. These boards usually come pre-installed with various interfaces necessary for FPGA development.

Uses of FPGA Boards

FPGA boards facilitate the evaluation and validation of product development, both in terms of the IC circuitry (hardware) related to the FPGA and the software needed to operate the FPGA. They offer versatility during the product development stage, allowing designers to verify the operation of the IC during the development process, even if the evaluation board with dedicated peripheral circuit components is still under development.

Principle of FPGA Boards

To operate an FPGA, essential components include the FPGA IC, a board connecting the IC to various power supplies and bias wiring, and embedded software on a PC for sending digital control signals. FPGA boards package and integrate these components, enabling the evaluation and verification of FPGA’s electrical circuit system operation.

FPGA boards often come with a variety of interfaces and function libraries from different manufacturers. However, more sophisticated models can be very expensive.

Other Information on FPGA Boards

1. Use of FPGA Boards

FPGA boards are used for preliminary evaluation and development of FPGA-based products, operation verification of embedded application software, IC evaluation and verification of digital circuits, and as introductory tools for FPGA-related design. They are available in a range of functionalities and complexities, from high-performance specialized boards to beginner-friendly ones. It’s important to select an FPGA board that suits the specific goals and requirements of the project.

2. Advantages of FPGAs Over ASICs

FPGAs have a built-in wiring system called Gate Array, allowing designers to programmably implement a variety of functions. While the performance of FPGAs may not match that of specially designed and optimized ASICs in terms of response speed and power consumption, they offer the flexibility of realizing desired functions immediately without incurring mask development costs. In the context of today’s advanced CMOS technology, where IC mask development can be both costly and time-consuming, FPGA boards are valuable tools for designers and developers, particularly when dedicated ASIC development is not feasible due to cost and volume considerations.

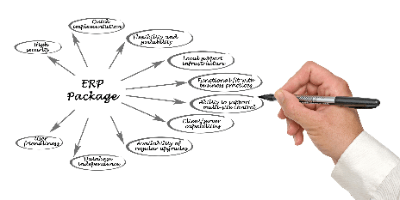

An ERP (Enterprise Resource Planning) Package is a system that integrates and manages the various operations of a company.

An ERP (Enterprise Resource Planning) Package is a system that integrates and manages the various operations of a company.

DLC coating, standing for Diamond-like Carbon, is a

DLC coating, standing for Diamond-like Carbon, is a

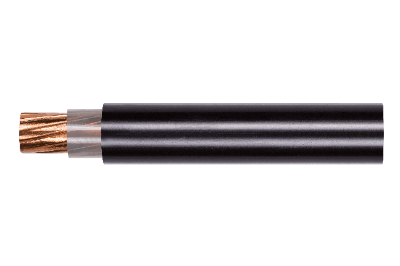

A CV cable, officially known as a “cross-linked polyethylene insulated vinyl sheath cable,” is commonly used in industrial power

A CV cable, officially known as a “cross-linked polyethylene insulated vinyl sheath cable,” is commonly used in industrial power  CG software, standing for Computer Graphics software, is used for creating and editing digital images on a computer. Users of this software are commonly referred to as CG creators.

CG software, standing for Computer Graphics software, is used for creating and editing digital images on a computer. Users of this software are commonly referred to as CG creators.