What Is an Impact Wrench?

An Impact Wrench is a wrench that uses electricity or compressed air to tighten hex bolts. The word impact comes from the hammer mechanism inside the wrench, which applies an impact

Usage of Impact Wrench

Impact Wrenches are mostly used in production sites. Unlike human-powered wrenches, they can work at high speeds, so they are often used in factories and construction sites where many hexagonal bolts are used, and in automobile repair shops where tires are changed.

With the popularity of DIY, they are also used in ordinary households and are readily available at home centers and through mail order.

Principle of Impact Wrench

First, a motor is rotated by electricity, which rotates a built-in hammer, and the impact in the direction of rotation rotates a socket connected to the tip of the shaft, enabling fast and strong tightening and loosening of bolts and nuts.

The main parts of an impact wrench are the power unit, the drive unit, and the socket.

1. Power Unit

The power unit is the driving force of impact wrench. A DC motor is mainly used for battery-powered wrenches and an AC motor for outlet-type wrenches.

2. Driving Unit

The drive unit is made of a spring or metal with a cylindrical groove cut in it, etc. When excessive torque is applied during rotation, the groove is removed and only the power part spins. This limits the torque and protects the power from overloading.

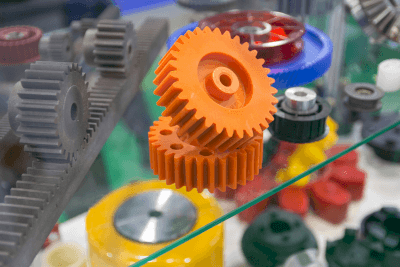

3. Socket Part

The socket part is removable and can be used for multiple bolt sizes, which is a feature of impact wrenches. Some products can be used not only for bolts but also for impact drivers by replacing the socket.

Types of Impact Wrench

1. Difference in Power Source

There are two main types of power sources for impact wrenches: rechargeable type and AC power source type.

Rechargeable impact wrenches use batteries, so there are no cables, and they are suitable for sites that require easy handling. Although most of them are heavier for the battery, the battery type is preferred by many due to its mobility.

The battery voltage of 10.8V, 14.4V, 18V, and 36V are the main types of batteries. However, they are relatively less powerful. 18V and 36V machines have more power to tighten and loosen bolts, but they are also heavier.

AC-powered models are lighter than rechargeable models because they do not have batteries. Also, AC-powered models are often less expensive than rechargeable models, even if they have the same performance.

In situations where many bolts are to be tightened, work can continue for a long time without worrying about the battery running out. If there is an electrical outlet nearby or if you work without moving much, you can take advantage of the characteristics of the AC-powered type.

2. Difference in Torque

Torque is the power to turn a bolt or nut when tightening or loosening it. How much torque can be tightened is indicated in Nm (Newton meter).

If the torque is too low for the work to be done, the motor will be overloaded, which may cause breakdowns. On the other hand, using too much torque may damage bolts and nuts. It is important to select a drive with full consideration of the conditions under which it will be used.

3. Difference in Size of Square Drive

There are five standardized sizes of square drives to be attached to impact wrenches: 6.3sq, 9.5sq, 12.7sq, 19.0sq, and 25.4sq. They are not interchangeable, and you must have a socket that matches the size of each square drive.

Incidentally, as the size of the square drive for mounting the socket increases, so does the ability to tighten and loosen bolts of larger sizes.

Other Information on Impact Wrenches

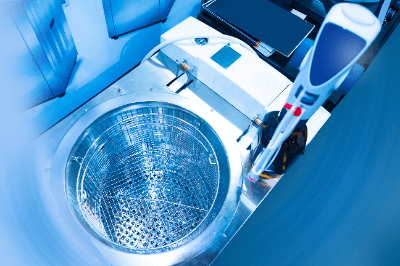

Air Impact Wrench

There are air impact wrenches that are driven by compressed air delivered from a compressor. Compared to rechargeable or AC-powered electric impact wrenches, these wrenches are more powerful yet smaller, but because they require an air compressor, they are often used in factories and other locations where they are not moved very often.

Glass is a substance composed primarily of silicon (element symbol: Si) and oxygen (element symbol: O).

Glass is a substance composed primarily of silicon (element symbol: Si) and oxygen (element symbol: O).