What Is a Power Distribution Panel?

A power distribution panel is a device that receives high-voltage electricity from a power plant, reduces the voltage, and distributes it to various endpoints, such as a polarization panel or control panel.

Often referred to as a “cubicle,” these panels are standard in most general households, distributing electricity from the main panel to lighting, electrical outlets, and other equipment.

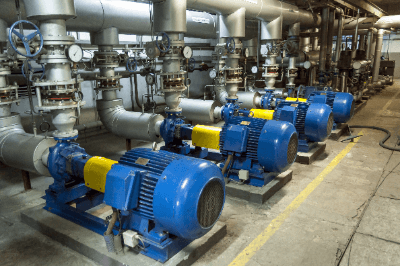

Control panels, an integral part of the system, manage the automatic or manual control of motors, pumps, electric motors, and heaters. They usually handle low voltages like 100 V, 200 V, and 400 V and are equipped with ammeters, lamps, switches, etc., on their door surfaces.

Uses of Power Distribution Panels

Power distribution panels are primarily installed in large buildings such as office buildings, stores, and factories with high-voltage power contracts. These panels receive high-voltage electricity (6,600kV to 7,700kV) and convert it to lower voltages suitable for powering production facilities and communication equipment.

Ordinary households, having low-voltage power contracts, typically do not require power distribution panels. These panels are often housed in box-like structures, approximately the size of a storage shed, and are usually installed outdoors on rooftops or in parking lot corners.

Principle of Power Distribution Panels

Power distribution panels function by receiving high-voltage electricity and distributing it at lower voltages. High-voltage transmission minimizes losses, and thus, large facilities such as office buildings and factories receive electricity directly from power plants at high voltages.

For safety, the equipment is designed to protect wiring from contact with foreign objects, people, and animals, and to prevent leakages and short circuits. In case of disasters like fires or earthquakes, the design minimizes damage to the equipment.

Types of Power Distribution Panels

Power distribution panels vary widely in application and are classified into distribution boards, monitoring boards, control boards, and terminal boards.

1. Distribution Board

A distribution board is a cabinet containing switchgear and circuit breakers, distributing power to various facilities like lights and outlets. It’s designed for safe use, even by individuals without electrical knowledge, and typically features a protective board covering all parts of the circuit breaker except the knobs.

2. Monitoring Panel

A monitoring panel centrally manages data from various monitored objects spread across a facility.

3. Control Panel

Control panels manage the power supply to electric motors for air conditioning, sanitation, fire protection, etc., and are housed in cabinets containing necessary operational, protective, and monitoring equipment. These panels often have ammeters, lamps, switches, etc., on their door faces.

4. Terminal Board

A terminal board is used at electrical circuit connection points and test cutoff points, featuring numerous terminals for installation.

How to Select a Power Distribution Panel

Power distribution panels are typically installed in large facilities like factories, schools, and buildings with high-voltage contracts. In contrast, they are not necessary in standard homes with low-voltage contracts. The cost of electricity is generally higher under a low-voltage contract than a high-voltage one.

Almost all buildings, including houses and condominiums, have distribution boards to distribute electricity to each room. These boards are crucial for preventing risks like electrical leakage and ensuring safety. Large buildings often have both distribution panels and power distribution panels.

Structure of Power Distribution Panels

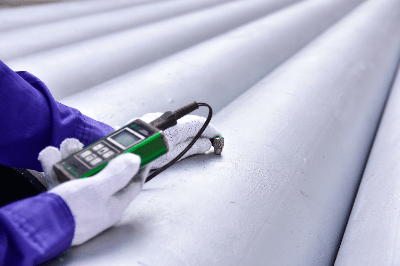

Power distribution panels combine monitoring and control equipment with main circuit equipment, mounted on a panel to facilitate control, monitoring, and protection of electrical circuits. This includes meters, switches, relays, disconnectors, circuit breakers, transformers, and load switches.

There are two main construction types: closed, where all equipment is enclosed in a box, and open, where equipment and steel frames are exposed. Closed types have become more common due to their safety, factory-assembled reliability, and ease of installation.

The panels include devices for controlling and monitoring electricity, such as meters, and circuit breakers for interrupting the electric current in case of abnormalities in the electrical circuit.