What Is Forming Machinery?

Forming machinery is a processing machine capable of performing multiple processes such as pressing, bending, and cutting of wire and plate materials, such as coils, in a single machine. It can continuously produce parts such as springs, coils, clips, and rings.

Within the category of forming machinery, there is a specialized machine for producing spring parts known as a wire-forming or spring-forming machine.

Recently, these machines have evolved to handle a wider variety of processing tasks, including integrated processes like swaging, component assembly, welding, header processing, and forging.

Uses of Forming Machinery

Forming machines are used in the manufacturing of springs, such as compression coil springs and leaf springs, commonly found in automobiles, home appliances, various construction materials, industrial machinery, agricultural machinery, and stationery.

Many of these machines can handle wire diameters as small as several millimeters, and they are used to manufacture a wide range of parts, including snap pins, retaining pins, hose bands, rings, circlips, snap rings, hose clips, and wire clamps.

In some cases, parts that were conventionally fabricated using dies and press working have been transitioned to forming machinery to reduce production costs.

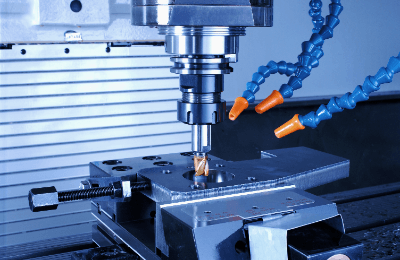

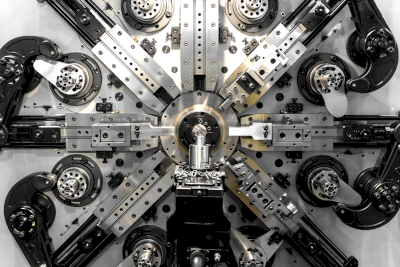

Principles of Forming Machinery

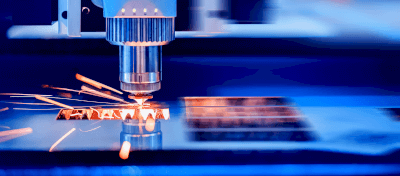

The processing process of forming machinery unfolds as follows: Initially, a feed device steadily supplies plates, coils, and other wire materials. A stamping device then shears and presses the materials, creating holes and forming them. Subsequently, multiple forming machines are employed to shape complex bends and three-dimensional forms, and additional processes can be performed in a single pass as required.

Utilizing forming machinery results in reduced material wastage and manufacturing costs through continuous processing. Moreover, in comparison to progressive presses with similar functionalities, forming machines feature a more straightforward structure, contributing to reduced die costs for the processing machine.

Initially used for mass production of simple products, forming machinery has become increasingly sophisticated with advancements in technology. It can now be integrated with NC (numerically controlled) machines to produce complex-shaped parts at a lower cost.