What Is Bronze Pipe?

Bronze pipe is a piping system with very good thermal conductivity and corrosion resistance.

Bronze pipe is also highly flexible and easy to install. Piping is divided into metallic and non-metallic tubes according to material. Metallic tubes include steel, stainless steel, and aluminum tubes, while non-metallic tubes include polyethylene, polybdenum, and polyvinyl chloride tubes.

They are often used in building equipment, heating and cooling systems, and industrial applications. There are two main types of bronze pipe: soft and hard. Soft bronze pipe is bendable and suitable for piping work, while hard bronze pipe is less bendable and used for construction applications and high-pressure piping. Bronze pipe is more expensive than steel pipe, but it is an environmentally friendly material with high recyclability.

Uses of Bronze Pipe

1. Buildings

Because of its light weight, corrosion resistance, and antibacterial properties, copper tubing is used in tight spaces such as the backs of buildings and in piping for hot water and drinking water. It is flexible and easy to process, and can be manufactured in complex shapes and connected with crimp fittings or brazing.

2. Heat Exchanger

With high thermal conductivity, steel pipes are used in heat exchangers, solar thermal power generation, and other equipment that heats or cools. Steel tubes have high strength but low thermal conductivity, making them vulnerable to rapid temperature changes and possible deformation or breakage. Bronze pipe, however, is highly flexible and corrosion resistant, giving it a long service life.

3. Other

Bronze pipe is used in a wide variety of fields, including automotive motor parts due to its high electrical conductivity, CPU cooling systems for PCs and game consoles due to its high thermal conductivity, and medical gas piping due to its high corrosion resistance.

Features of Bronze Pipe

1. Antibacterial Properties

Copper tubing has been proven to inhibit the growth of Escherichia coli O-157 and Legionella bacteria, and to inactivate the infectivity of influenza and norovirus viruses. It was once believed that “green rust,” a type of copper rust, was a toxic substance, but this has now been verified to be harmless.

2. Corrosion Resistance

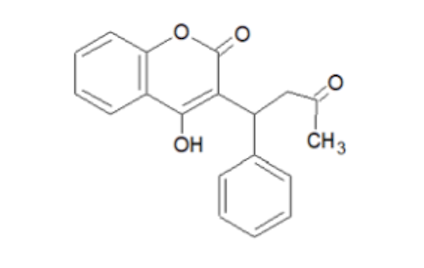

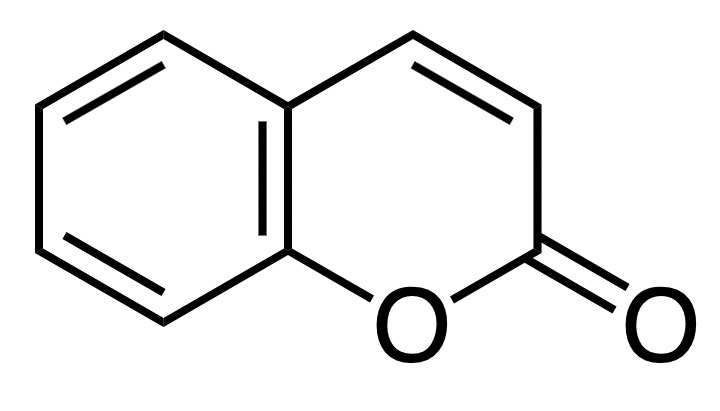

Corrosion is prevented by forming an oxide film bonded with oxygen on the surface, but acid, alkali, sulfur compounds, seawater, and sea breezes can corrode it. As with steel pipes, painting or corrosion inhibitors should be used. Chromic acid and benzotriazole are used as corrosion inhibitors, and resin-based epoxy resins are used for coating.

3. Thermal Conductivity

Because it conducts heat about 7 times more easily than iron and 20 times more easily than stainless steel, it is used in heating equipment, cooling equipment, mold cooling piping, refrigeration piping, and heat exchangers for air conditioning. Gold and silver are also effective in heat transfer, but they are very expensive and cannot maintain their strength, so copper is the most economically rational.

4. Workability

Soft bronze pipe can be easily bent, allowing for dense piping in tight spaces or to increase the contact area. However, small-diameter piping can be bent even by hand and may be bent or damaged by contact after installation.

5. Low-Temperature Resistance

Copper has superior low-temperature brittleness compared to iron. At low temperatures, iron tends to become brittle and is sensitive to sudden temperature changes. However, copper is relatively tough under such conditions and exhibits better wear and corrosion resistance than iron.

This is due to copper’s high thermal conductivity and low coefficient of thermal expansion, properties that are stable even at high temperatures.

6. Electrical Conductivity

When used with piping for wiring, the tube itself can be used as a grounding wire to prevent electrical leakage.

Types of Bronze Pipe

Copper tubes are classified by outer diameter, tube thickness, bending radius, and pressure resistance performance.

1.Oxygen-Free Bronze Pipe

Also called “O” material, this is a soft tube available in straight and coiled forms. It is widely used for wiring, refrigerant pipes, water pipes, etc.

2. Oxygenated Bronze Pipe

O-el material and its properties are similar to those of oxygen-free copper. Tough pitch copper is a typical example and is less expensive than oxygen-free copper. However, when heated above 600°C, hydrogen embrittlement occurs, which may cause cracking and splitting.

3. Semi-Hard Bronze Pipe

It is mainly used in refrigerant straight pipes. Since it can be bent with a bender, it is used in places where pressure is applied and complex shapes are required, such as automotive pipes.

4. Hard Bronze Pipe

Also called hard material, it is very hard and strong and cannot be bent. It is used in places where strength is required, such as construction piping, refrigeration piping, and hydraulic piping.

It is stable in a solid state at room temperature, but is soluble in alcohol, ether,

It is stable in a solid state at room temperature, but is soluble in alcohol, ether,