What Is a Magnetic Chuck?

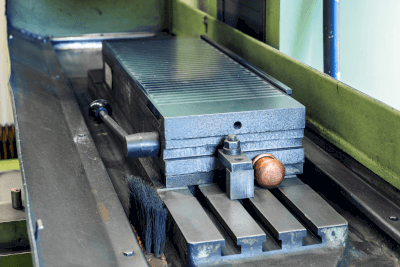

A magnetic chuck is a specialized device used in machine tools to securely hold metal workpieces. Featuring permanent magnets, it generates a magnetic force to keep the workpiece in place during machining operations, without needing an external power source. This design leads to significant energy efficiency and ease of use.

However, adjusting the magnetic force of a permanent magnetic chuck can be more challenging compared to electromagnetic chucks. It’s also important to note that the magnetic force may decrease in high-temperature environments.

Uses of Magnetic Chucks

Magnetic chucks are essential in various machining processes, particularly in:

1. Grinding

They are used in grinding operations for high-precision surface finishing of metal workpieces, such as in the production of gears and bearings.

2. Milling Machines

Magnetic chucks provide stability for workpieces in milling machines, aiding in detailed cutting and profiling.

3. End Milling Machines

They hold small metal parts securely in end milling machines, facilitating precision drilling and machining.

Principle of Magnetic Chucks

The principle behind magnetic chucks involves permanent magnets creating a steady magnetic force to hold the workpiece. This setup ensures stable, efficient, and energy-saving operation during machining, as it does not require an electrical power supply.

How to Select a Magnetic Chuck

Key considerations for selecting the right magnetic chuck include:

1. Size

Choose a chuck size that fits the workpiece, ensuring it sits securely on the chuck‘s surface.

2. Holding Power

Select a chuck with adequate holding force for the weight of the workpiece, ensuring safety and effective operation.

3. Flatness

For precision machining, opt for a chuck with high flatness accuracy to maintain quality in the finished product.