What Is a 30-Degree Trapezoidal Screw?

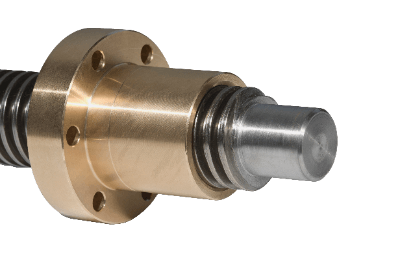

Screws, crucial for assembling various products, come in different types based on their thread shapes. Among them are triangular screws with triangular threads, square screws, and trapezoidal screws, which have trapezoidal threads. Trapezoidal screws are distinguished by their thread angles, typically 30 degrees in Europe and 29 degrees in the United States.

Screws, crucial for assembling various products, come in different types based on their thread shapes. Among them are triangular screws with triangular threads, square screws, and trapezoidal screws, which have trapezoidal threads. Trapezoidal screws are distinguished by their thread angles, typically 30 degrees in Europe and 29 degrees in the United States.

Uses of 30-Degree Trapezoidal Screws

30-degree trapezoidal screws are utilized in diverse applications, including as adjustable screws in tool machines, operating equipment, lifting equipment, forklifts, injection molding machines, and assembly lines. They are preferred for their minimal backlash, high strength, ease of manufacturing, precision machining, and efficient conversion of rotational motion into axial movement.

Principles of 30-Degree Trapezoidal Screws

While triangular threads are commonly used in machine parts for their high frictional force, trapezoidal screws, with their unique thread design, offer high strength and are ideal for power transmission applications. These include feed screws for lathes and other machine tools, as well as valve openers and closers requiring precise motion transmission. The 30-degree angle of these screws is a standard in European trapezoidal screws, distinguishing them from other types.

Compared to square screws with square threads, trapezoidal screws are easier to manufacture and can be machined with finer pitch, making them ideal for applications requiring high-precision pitch. Their efficiency in converting rotational motion into axial movement also makes them suitable for jacks used in lifting heavy objects and for press screws.