What Is a Bearing Nut?

A bearing nut is a component used to fasten a bearing.

The lock nut is also used as a synonym. There are several ways to fasten a bearing, and fastening with a bearing nut is one of them. A bearing nut is mainly used to tighten and secure the inner ring of a bearing.

Uses of Bearing Nuts

Bearing nuts are used for fastening bearings. This is mainly the case when bearings are used at the shaft end.

Especially when bearings are fastened to shafts with removal sleeves, different size bearing nuts are used for tightening and removal. When used as a shaft support component on rotating machinery where the shaft rotation direction is clockwise, left-hand threaded bearing nuts are often used because the nut threads easily loosen in the same direction as the rotation direction.

Principle of Bearing Nuts

When using bearing nuts to fasten a bearing,

The following methods are available for fastening bearings using bearing nuts.

1. Fastening Cylindrical Bore Bearings

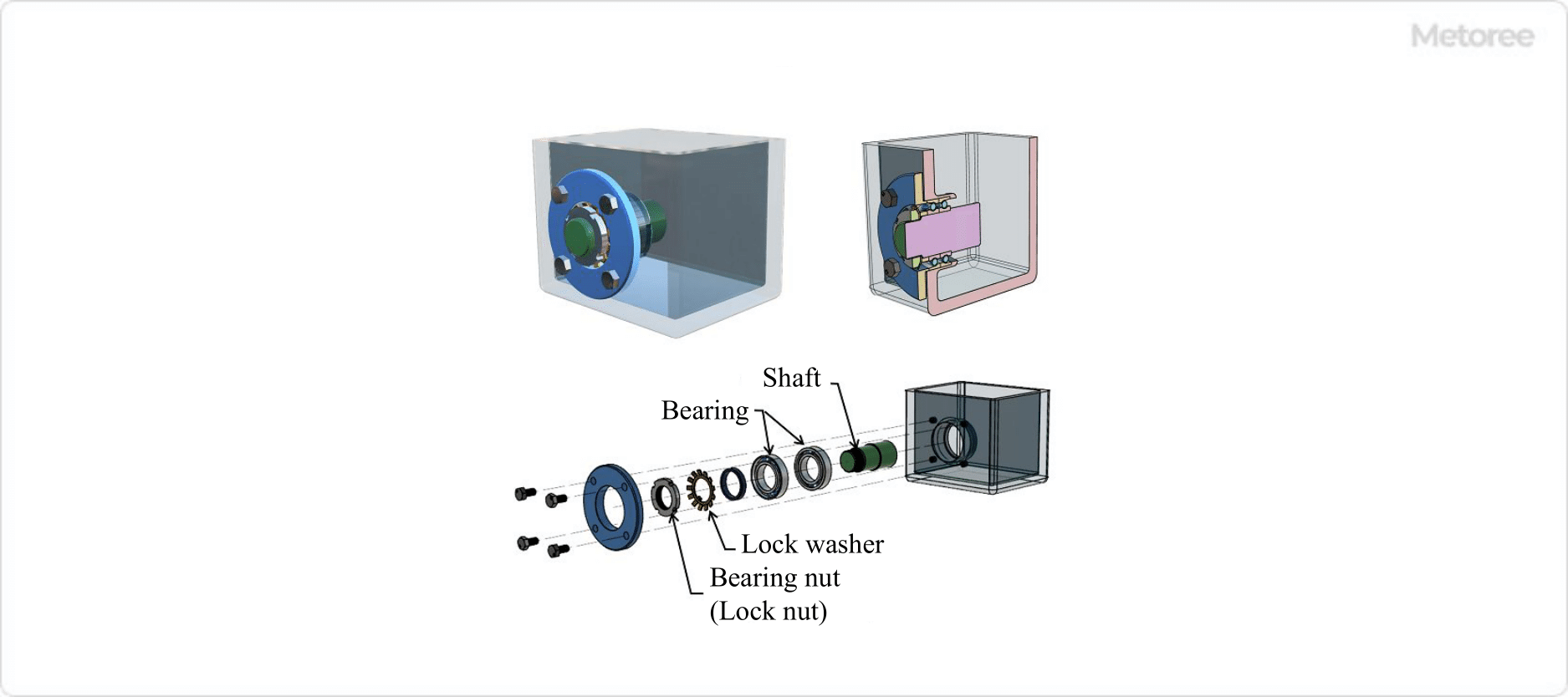

Figure 1. Principle of bearing nut

Bearing nuts are used as an example when fastening a bearing with a cylindrical bore in the inner ring to a shaft. The bearing nuts are screwed onto the male thread machined on the shaft end and used to press the inner ring to fix it in place.

Lock washers are sometimes used to prevent the bearing nuts from loosening. The lock washer has a flange on both the inner and outer diameters. The inner diameter side engages with the shaft groove and the outer diameter side engages with the bearing nuts groove, restraining and securing the bearing nuts in the direction of rotation.

2. Fastening of Tapered Bore Bearings

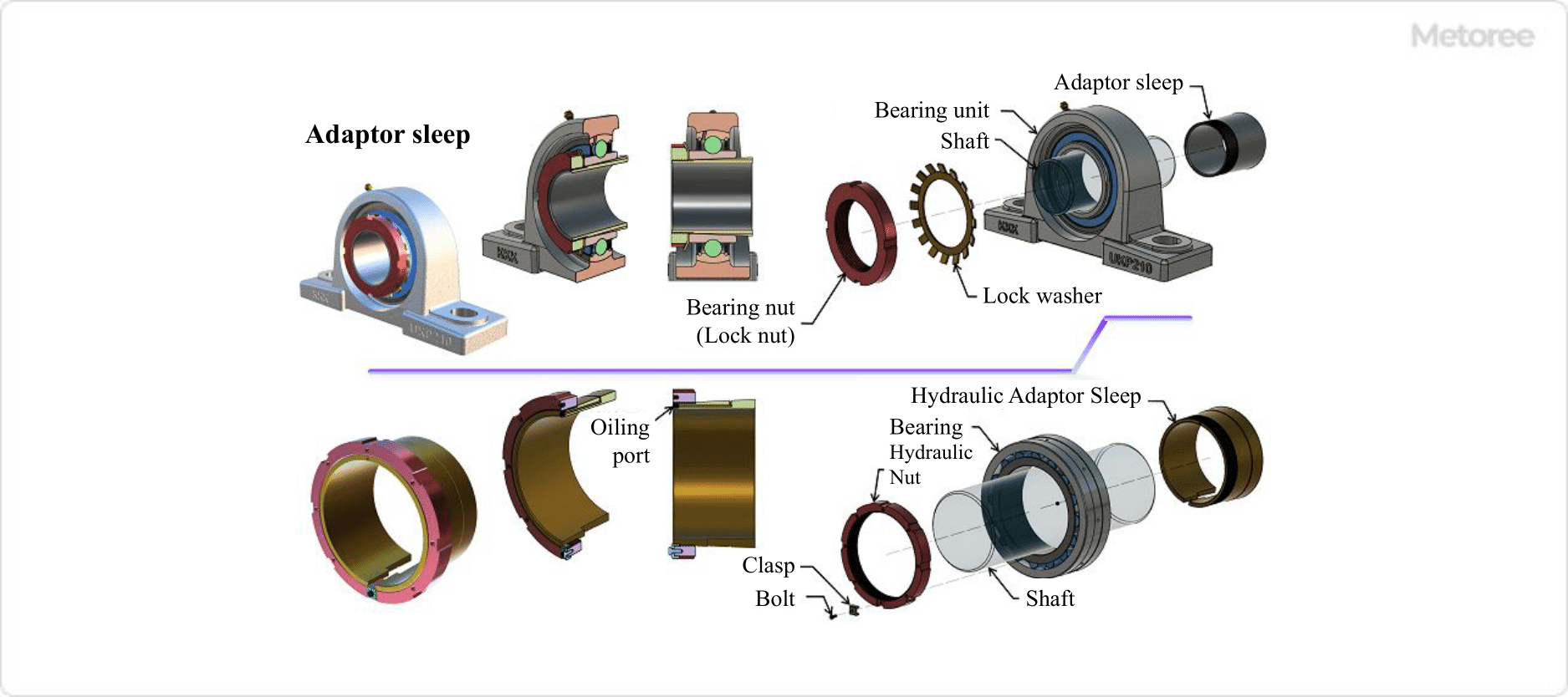

Figure 2. Example of bearing nut use (1)

Figure 3. Example of bearing nut use (2)

As an example of fastening a bearing with a tapered inner ring bore to a shaft, an “adapter sleeve” or “removal sleeve” and bearing nuts are used. When using an adapter sleeve and bearing nuts, fit the adapter sleeve onto the shaft and screw the bearing nuts onto the male thread of the adapter sleeve, so that the adapter ring is pushed in, and the fit between the inner ring and adapter ring becomes stronger, and the inner ring is fastened to the shaft. The inner ring is then fastened to the shaft.

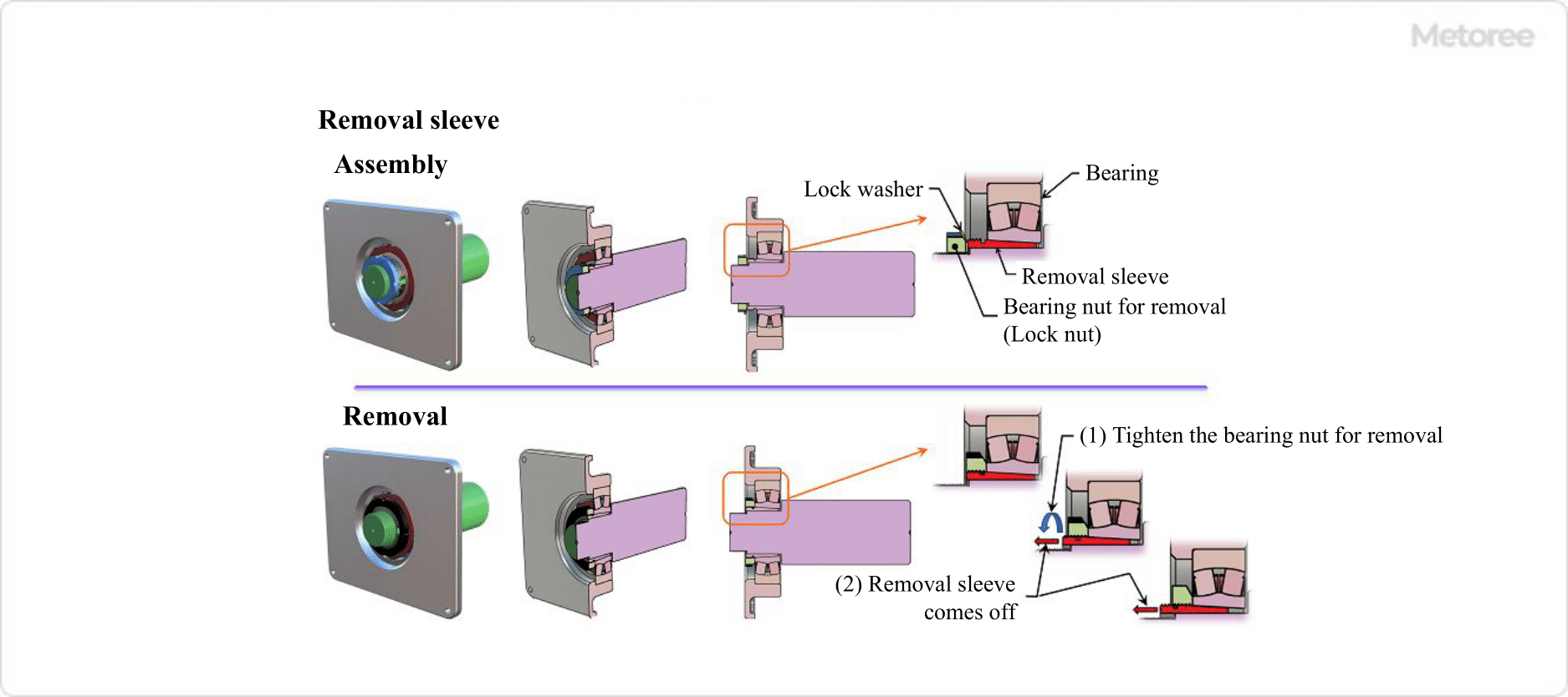

When using the removal sleeve and bearing nuts, insert the removal sleeve onto the shaft and screw the bearing nuts onto the male thread of the removal sleeve, which pushes in the removal sleeve to strengthen the fit between the inner ring and the removal sleeve and fasten the inner ring to the shaft. The inner ring is fastened to the shaft.

Note that when the removal sleeve is used, the bearing nuts are also used to remove the bearing. By screwing the bearing nuts onto the male thread at the shaft end, the removal sleeve is pulled out to loosen the fit between the inner ring and the removal sleeve, and the inner ring and shaft are released.

Types of Bearing Nuts

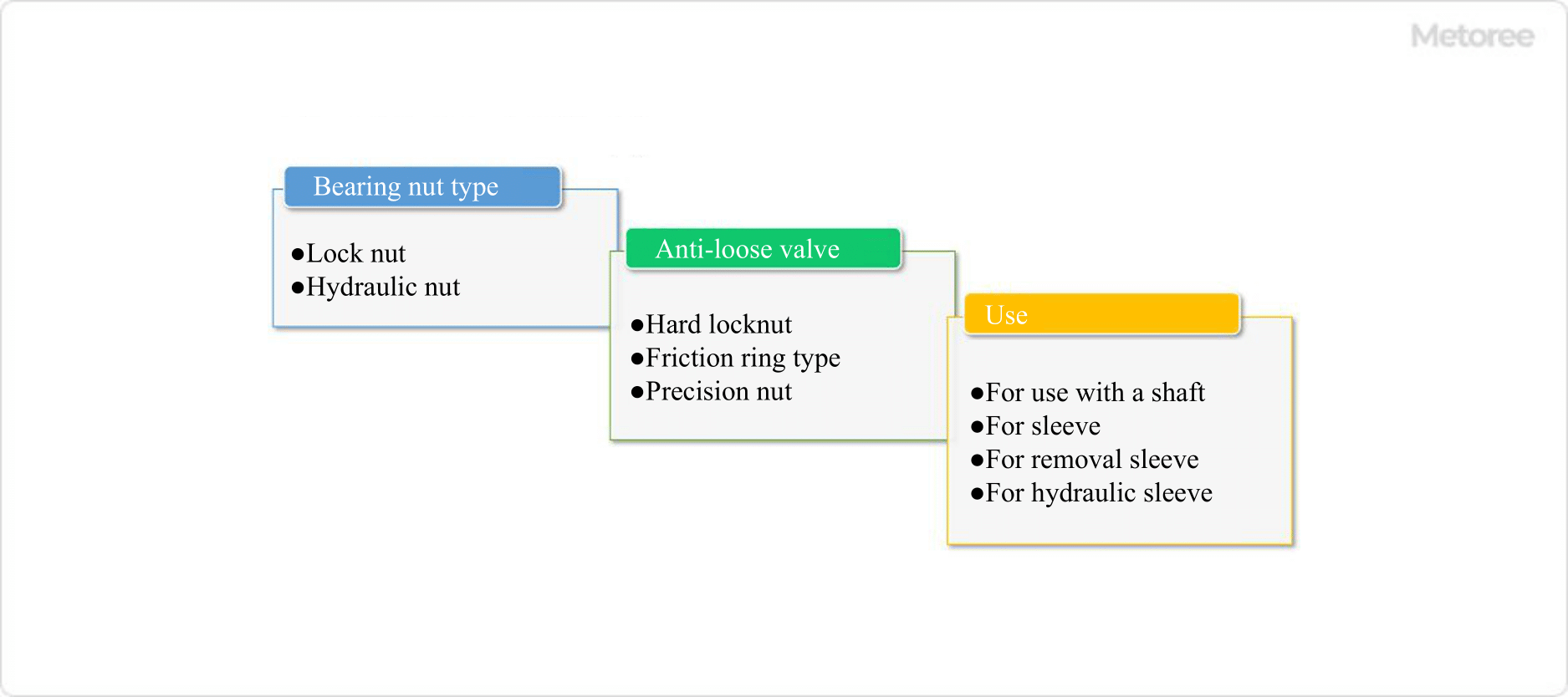

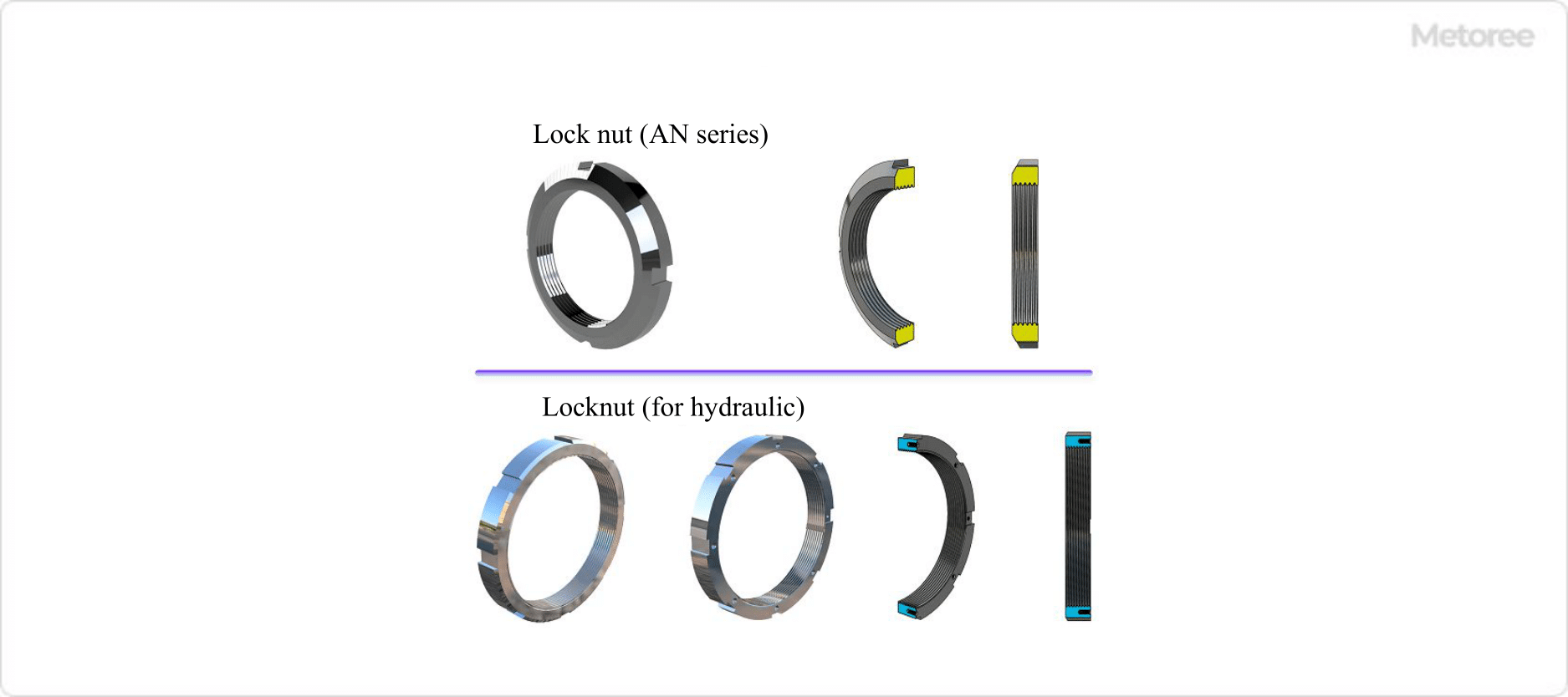

Figure 4. Types of bearing nuts (1)

The types of bearing nuts can be classified as shown in the above figure according to type, type of loosening prevention, and application.

1. Type

Figure 5. Types of bearing nuts (2)

- Lock nut

This is a bearing nut that is secured only by screw tightening. - Hydraulic nuts

Hydraulic nuts can be assisted during mounting and dismounting by hydraulic pressure and have an oil feed port on the bearing nut.

2. Looseness Prevention

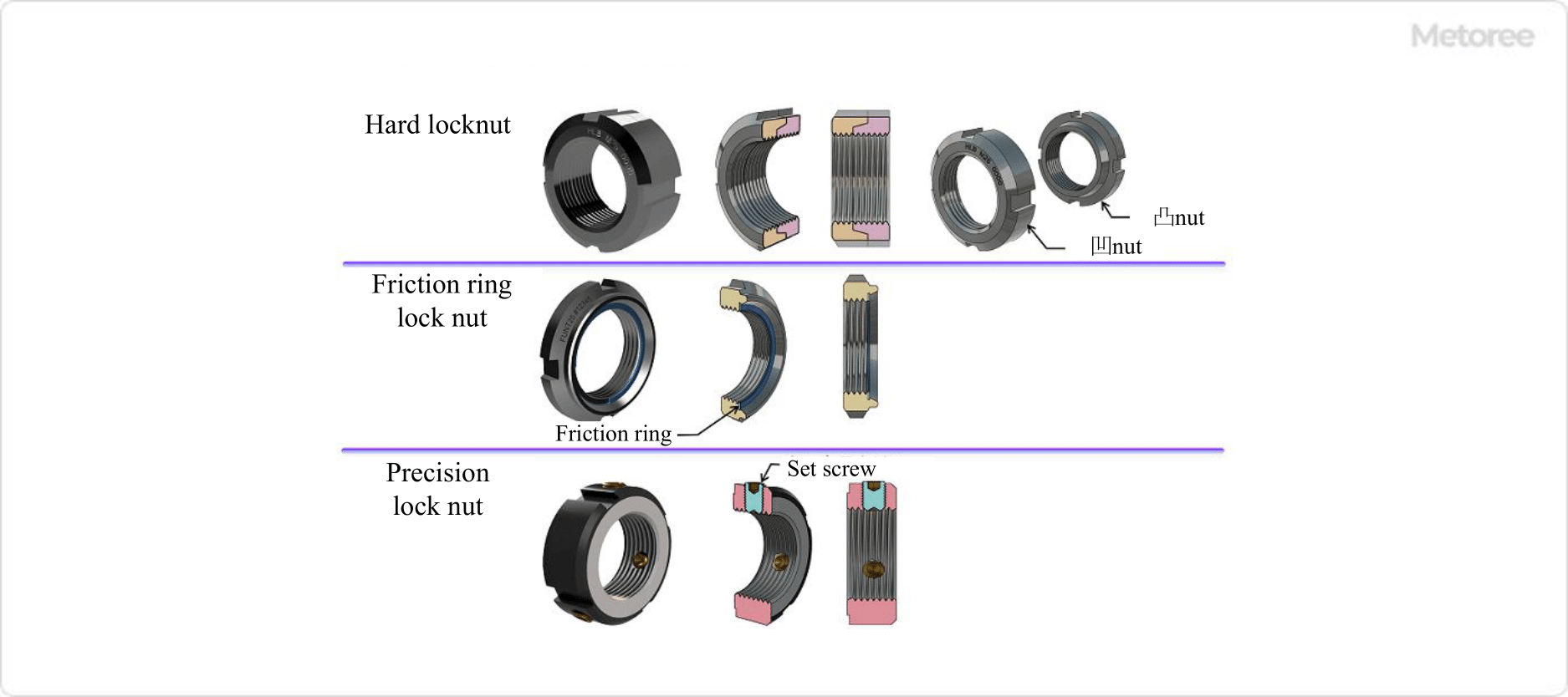

Figure 6. Types of bearing nuts (3)

- Hard Lock Nut

Similar to the hard lock nut for general lock nuts, this is a wedge-shaped nut with two types of eccentricity, concave and convex. The entire thread of the convex nut is pressed against the bolt side, and the entire thread of the concave nut is pressed against the bolt thread on the opposite side, working as a “wedge” effect to prevent loosening. - Friction Ring Type

When the bearing nut is screwed on, the friction ring at the end of the nut contacts the shaft thread, and the friction ring deflects to press against the shaft thread contact surface to prevent loosening due to frictional resistance. - Precision Nuts

This is a bearing nut machined with high runout accuracy against the rotating shaft, featuring good balance during rotation and resistance to loosening. A type in which the set screw is tightened to the shaft is also available.

Other Information on Bearing Nuts

1. Mounting Direction of Bearing Nuts

The chamfered side of the bearing nuts is the bearing side. The lock washer is installed along this chamfered side. The model number of the bearing nuts, such as AN10, is stamped on the non-chamfered side of the bearing nuts, making it easy to see when removing the nut.

2. Tightening the Bearing Nut

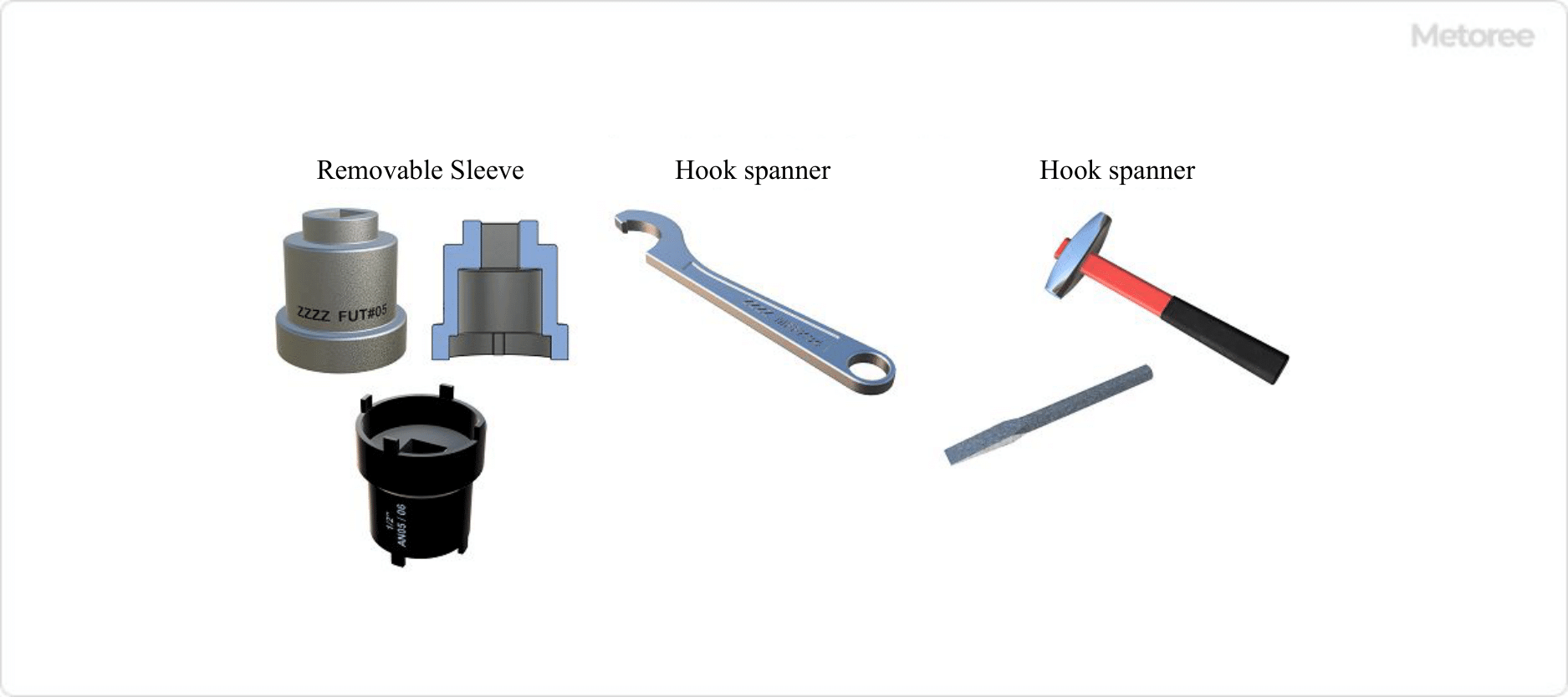

Figure 7. Tool for bearing nut

Loosening of the bearing nuts due to vibration while the equipment is in operation may cause abnormal noise or damage to parts including bearings. Therefore, it is important to tighten the bearing nuts with appropriate tools. The following types of tools are available for tightening bearing nuts:

Sockets for bearing nuts (locknut sockets)

Sockets for wrenches to tighten bearing nuts. The size is selected to fit the outer diameter of the bearing nuts and is attached to a standard socket wrench.

Hook spanner

This is a wrench-type tool for tightening bearing nuts. The convex part of the hook is hooked onto the concave part of the bearing nuts and rotated using the principle of leverage to tighten the nut. Use a hook spanner of the appropriate size for the outside diameter of the bearing nuts. This wrench can be used effectively in places where bearing nuts wrench cannot fit.

Hammer

Hammers are used for tightening and retightening the bearing nuts. Place the flat hammer in the recess of the bearing nuts and tap it in with the hammer. This is one of the methods to prevent loosening. This method is used when a wrench or similar tool is not strong enough. As a precaution, impact is applied to the recess of the bearing nuts so that it does not come off and damage other parts of the bearing nut. Also, be careful not to hit it too hard, as it will crush the recess of the bearing nuts.