What Is a Turbofan?

Turbofans are centrifugal fans that sucks in air and redirect it 90° to the intake direction, increasing static pressure. This characteristic makes turbofans suitable for applications requiring gaseous blasts through ducts, and is utilized across industrial equipment and home appliances.

Uses of Turbofans

Turbofans find applications in numerous sectors, enhancing efficiency and versatility:

- Jet Engines: Central to aviation, turbofans power airliners and fighter jets with high efficiency and thrust.

- Industrial Use: Essential for cooling personal computers and managing heat in precision equipment, maximizing performance.

- Ventilation Systems: Vital in building and home ventilation, turbofans facilitate effective ventilation through duct connections, improving indoor environments.

Principle of Turbofans

Operating on centrifugal force, turbofans push air outward as they rotate, sucking in air and blowing it out at a 90° angle. Despite their potential for higher noise levels, their significant static pressure and volumetric flow rate make them suitable for a wide range of uses. The air volume output is influenced by blade number, width, and rotation speed.

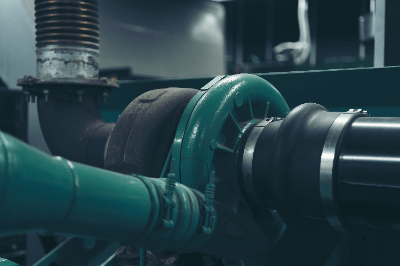

Structure of Turbofans

Characterized by their high blowing capacity, turbofans have backward-mounted blades at their core, differing from sirocco fans, which have forward-facing blades. This design efficiently draws in and expels air.

Types of Turbofans

Turbofans vary by design, functionality, and intended use:

- Axial Flow Turbofan: Common in large engines and industrial settings, air flows linearly along the axis.

- Centrifugal Turbofan: Air flows radially outward, fitting for compact appliances and small equipment.

- Mixed-Flow Turbofan: Blending axial and centrifugal features, used in medium installations and some industrial applications.