What Is an Air Clamp?

Air Clamps are clamps that operate using compressed air.

A clamp is a device that holds an object in place by pressing down on it. It is possible to press down with more force than manual operation. Widely used in factories, it is one of the indispensable tools for processing materials such as metal products and wood.

Since they do not use electricity, they reduce the risk of fire or electric shock at the work site. However, proper maintenance is required, and regular lubrication keeps the clamps running smoothly and extends their service life. It is also important to set the air pressure appropriately, as excessive air pressure can cause damage to clamps and work pieces.

Uses of Air Clamps

Air Clamps are widely used in factories. The following are the main applications of Air Clamps:

1. Metal Processing

Air clamps are used for cutting metal plates and pipes in metal processing. They are also indispensable tools in processes such as welding and bolting. Air Clamps are capable of high torque and force, allowing work to be performed with a high degree of precision.

2. Woodworking

Air clamps are used for cutting and drilling in woodworking. They are also used for gluing wood. They can hold wood firmly, which improves the accuracy of work.

3. Automobile Maintenance

In automotive maintenance, air clamps are used to replace or adjust engine parts and change tires. The high torque of Air Clamps firmly holds heavy automotive parts.

4. Painting

Air clamps are sometimes used to secure spray guns in painting applications. Spray guns secured by Air Clamps are less likely to shake, thus ensuring a uniform coating.

Principle of Air Clamp

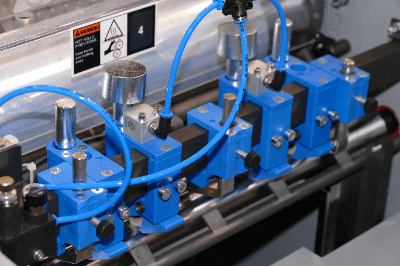

Air Clamp is a type of toggle clamp that uses compressed air as its power source to hold an object in place. The source of compressed air is generally a device such as an air compressor. The compressed air is sent to the Air Clamp through an air line.

Inside the Air Clamp is a cylinder that opens and closes the clamp. The cylinder can close the clamp by pushing up the piston as compressed air flows in, and open the clamp when air is removed from the cylinder. The operation is generally controlled by a solenoid valve, which is operated by sending commands to the solenoid valve through button operation or a foot pedal.

A toggle mechanism is often used for the clamping part. The toggle mechanism is a type of link mechanism consisting of two links and a slider.

Types of Air Clamps

Air Clamps are widely used in various industries. The following are examples of Air Clamp types:

1. Integrated Air Clamp

Integrated Air Clamps are air clamps with the clamp and cylinder integrated into one unit. They feature a compact design and can be used in any installation location. Another advantage is that they are easy to install.

2. Parallel Gripper

This clamp is made of multiple arms. The arms move in parallel with each other to firmly grip an object. This type of clamp is particularly effective when handling large items.

3. Rotary Clamp

This clamp can process an object while rotating it. Since the clamp can be rotated while holding the workpiece in place, work efficiency is greatly improved.

How to Select an Air Clamp

Air Clamps are useful tools that greatly improve work efficiency, but there are a few important points to keep in mind when selecting the right Air Clamp.

1. Intended Use

Select the appropriate size and force for your application. Larger Air Clamps with greater force are suitable for handling large parts, whereas smaller Air Clamps are better suited for handling smaller parts.

2. Shape

Various shapes are available, including straight and angled types, and mounting methods such as base mounting and flange mounting can be selected. It is important to select the appropriate shape and mounting method according to the work to be performed and the installation location.

3. Clamping Speed and Repeatability

Clamping speed and repeatability are also important factors that greatly affect work efficiency. A high clamping speed is required when performing a large number of operations in a short time. High repeatability is also important for precision work.