What Is a Coater?

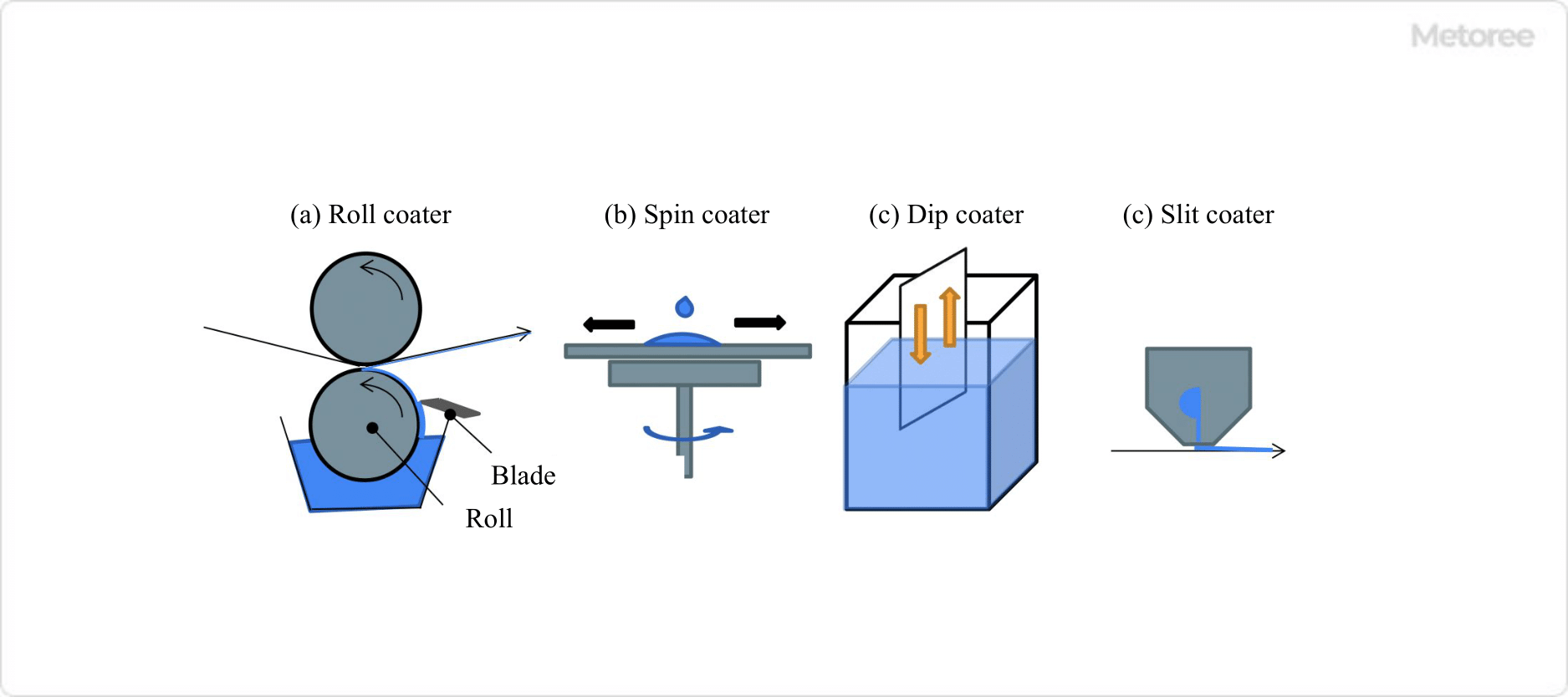

Figure 1. Types of Coaters

A coater is a device used to apply chemicals or other materials to a product or material.

General coater methods vary depending on the shape of the object to be coated, the chemical to be applied, and the purpose of the application. Therefore, roll coaters, spin coaters, dip coaters, and slit coaters are used for various applications.

In recent years, coaters have evolved dramatically along with improvements in coating technology, as precision coating accuracy is required in the fields of semiconductor manufacturing, flat panel display (FPD) manufacturing, solar cell and rechargeable battery manufacturing.

Uses of Coaters

In the semiconductor and flat panel display (FPD) manufacturing fields, where thin, high-functionality, and high-density products are required, such as PCs, LCD TVs, smartphones, and tablets, spin coaters, and slit coaters are used to apply photoresist in the photolithography process.

Roll coaters and other coaters for thin film coating are also used for functional films and sheet products used in rechargeable batteries, solar cells, automotive parts, housing construction materials, textiles, medical care, and other applications.

Principle of Coaters

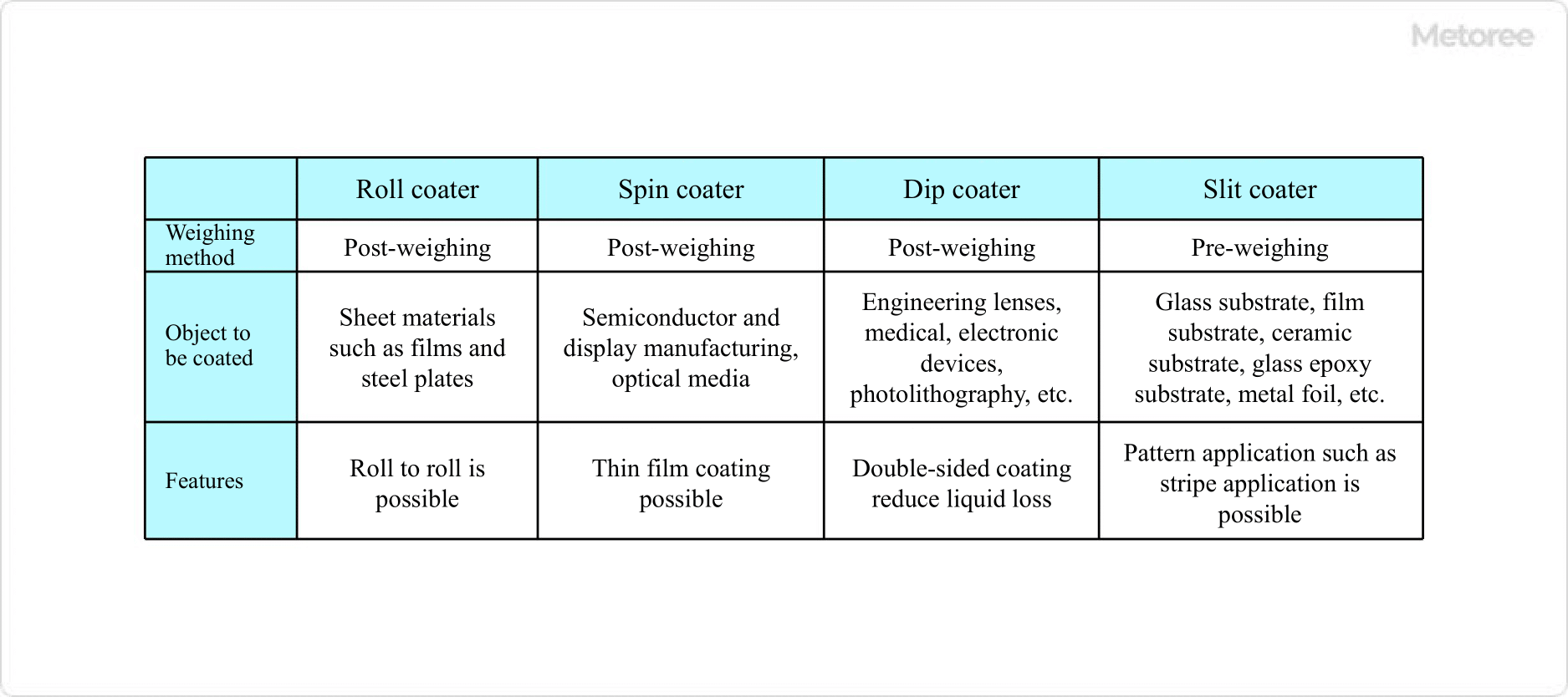

Figure 2. Characteristics by the Coater type

There are many types of coaters, but the basic principle is to apply shear force to the coating liquid to make it thinner. The way the shearing force is applied differs depending on the type of coaters.

The coaters can be classified into two types: the pre-measuring method, which applies a pre-measured amount of coating liquid, and the post-measuring method, which reduces the amount of coating liquid to a predetermined level after coating.

1. Roll Coaters

Roll coaters are generally used for coating relatively thin and flat materials such as films and sheets. Various coating methods are used depending on the nature and viscosity of the chemical to be coated, and the film thickness to be applied, such as gravure coaters and reverse coaters, which use the rotation of rollers in contact with the liquid pool of the chemical to be coated and the winding rotation of the film or sheet material to apply the coating.

The roll-to-roll coating is possible and is the most suitable for high-speed coating. The characteristic feature of these methods is that a bead is formed between the coating liquid and the object to be coated, and the object to be coated or both the object to be coated and the roll are moved or rotated to apply a shear force to the coating liquid and apply a thin coating. Stabilizing this bead is essential for high-quality coating.

2. Spin Coaters

Spin coaters generally consist of a rotating table and a mechanism for applying chemicals. After the chemical is discharged onto the product or other material, a centrifugal force from the table’s rotation spreads the chemical throughout the product or other material, forming a chemical film. This is the thinnest coating method, but it is not suitable for mass production because it cannot apply multiple coats and continuous production is not possible.

3. Dip Coaters

This is called the dip coater-dip method and is used for coating by dipping and pulling up in the dip coating solution. Regardless of the shape of the object, it is characterized by its ability to form a uniform thin film with minimal loss of coating liquid.

4. Slit Coaters

The slit coaters are coaters that discharge the coating liquid through a nozzle with a slit. It is also called die coaters or slot die. The object to be coated is placed on a table, and a chemical film is formed by scanning the product or other material while discharging the chemical from the chemical nozzle.

Sometimes used for roll-to-roll coating, the slit coaters dispense a constant amount of coating solution onto a film or sheet being conveyed. Since the coating fluid does not come in contact with air, it is ideal for the highest quality coatings and for complex coatings such as stripes.

Other Information about Coaters

Coating Defects

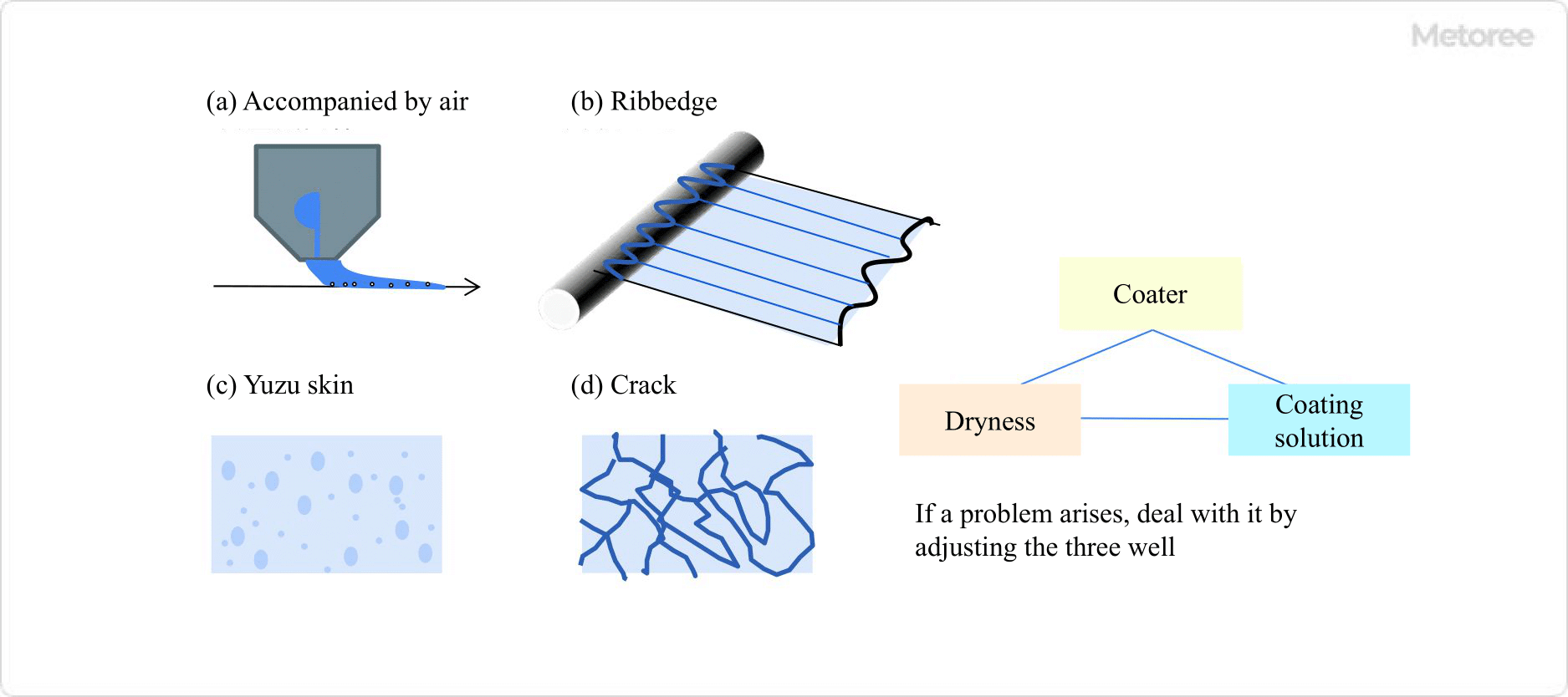

Figure 3. Typical example of Coating defects

No matter how sophisticated the coater is, depending on the coating liquid and coating conditions, it may not be possible to obtain a clean coated surface. This section briefly describes the types of coating defects and their remedies.

1. Those caused by Coating

| Type of defect | Cause | Remedy |

| Air entrainment | Air cannot escape when the coating liquid is applied to the coated object. | Reduces the coating speed. |

| Livestock | Livestock is subjected to a reverse pressure gradient in the coating section in the direction of the coating. | Reduction in viscosity of the coating liquid and coating speed. |

| Holes caused by air bubbles | Bubbles exist in the coating liquid. | Take measures to eliminate bubbles. |

| Unevenness in the shape of a horizontal dam, | mainly due to the reverse gravure method. | Suppress vibration of the coated object or change the rotational speed of the gravure. |

| Unevenness | Coating liquid flows in the coating film. | Improve the coating liquid. |

| Foreign matter | Coating liquid agglomerates or becomes gelatinous. | Introduce a filter. |

| Flickering | The surface tension of the coating liquid is too high. | Add a surfactant, etc. |

2. Defects caused by Drying

| Type of defect | Cause | Remedy |

| Orange-peel skin (The coated surface becomes uneven like orange peel.) |

This is due to an excessively fast drying rate. | Reduce the drying speed or add a surfactant. |

| Wind pattern | Hot air drying | Reduce the speed of hot air. |

| Cracking | Shrinkage of coated film | Avoid thick coating. |

Coating is a technique that is accomplished through the proper selection of coaters, dryers, and coating liquid, respectively. It is important to select the appropriate coaters, taking into consideration the conditions of the coating liquid to be used and the specifications of the drying oven.