What Is a Geared Motor?

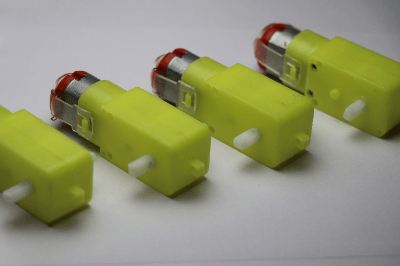

A geared motor is a device that combines gears and a motor. By combining gears and motors, the number of revolutions and torque can be designed as desired.

A geared motor is a device that combines gears and a motor. By combining gears and motors, the number of revolutions and torque can be designed as desired.

Compared to belt pulleys, geared motor produce less noise due to friction and are easier to maintain. The appropriate gear is selected by selecting the gear ratio based on the motor’s rotation speed and torque. The size of the gearhead must also be checked, as it requires space for the gearhead.

Mounting methods include flange-mounting and tap-mounting types.

Uses of Geared Motors

Geared motors provide high torque at low RPMs due to their gears. They are often used especially in large machinery such as food processing machines, multilevel parking garages, semiconductor manufacturing equipment, and woodworking machinery.

Familiar examples are also used in electric shutters and car washes. Taking advantage of their low RPM and high torque characteristics, they are also used in industrial robots.

Geared motors come in many sizes, from ultra-small to large. In addition, geared motors are available in a wide range of products, including those with electromagnetic brakes and those using stepping motors.

Principle of Geared Motors

Geared motors consist of a motor and a reduction gear.

While the motor rotates at high speed, the reduction gear adjusts the speed of rotation by combining gears. Geared motors have a high torque at a low rpm due to the reduction gear.

Three-phase induction motors are often used in industrial applications. Since the rated speed of induction motors is determined by the frequency and number of poles, the speed and torque are selected by adjusting the gear ratio.

The gear ratio is the rotation ratio of the motor rotation shaft to the reduction gear output rotation shaft. The higher the gear ratio, equates to the higher the torque.

The parallel or perpendicular shaft is selected according to the position of the gear and motor. A clutch brake type may also be used when the motor is frequently run and stopped.

How to Use Geared Motors

There are many ways to use geared motors, of which the most typical are deceleration, high load, and high precision.

1. Reduction of Speed

The rotational speed of a three-phase induction motor, for example, is determined by the number of poles and frequency. Therefore, to use induction motors at the required rotational speed, they are decelerated by a decelerator.

Since geared motors with various reduction ratios are sold by various companies, select a model that matches the required rotational speed.

2. High Load

The output torque increases in proportion to the reduction ratio due to deceleration, and the allowable moment of inertia increases in proportion to the square of the reduction ratio. This makes it possible to rotate large objects at the cost of reduced speed.

3. High Accuracy

When used for positioning operation, the stopping angle accuracy of the motor is improved.

For example, with a reduction ratio of 2, if the error of the motor output shaft is 1.0°, the error of the reducer output shaft is 0.5°, resulting in better accuracy. However, many reduction gears have play, called backlash, and care must be taken when using them for high-precision positioning.

Other Information on Geared Motors

Reduction Gears for Geared Motors

There are various types of reduction gears used in geared motors, which are selected according to the application. Typical examples include spur gear reducers, bevel gear reducers, hypoid reducers, worm reducers, planetary gear reducers, and wave gear reducers.

1. Spur Gear Reducer

Spur gear reducers are the most common type of gear reducer and use a combination of spur gears to reduce speed. They are also available in multi-stage types and can be manufactured with large reduction ratios, but they have a large backlash.

2. Bevel Gear Reduction Gears and Worm Reduction Gears

In bevel gear reducers and worm reducers, the input and output shafts are orthogonal. Worm reduction gears have a self-locking function and are often used in elevators.

3. Hypoid Reduction Gears

Hypoid reduction gears use spiral bevel gears and feature a large reduction ratio and smooth power transmission.

4. Planetary Gear Reducer

Planetary gear reducers are reducers that use planetary gears, and the input and output shafts are concentric. Planetary gear reducers are often used in stepping motors.

5. Wave Gear Reducer

Wave reduction gears are also called “harmonic reduction gears” after the company named Harmonic Drive Systems, which developed them. They are often used in robot joints as reduction gears with no backlash.

There are also ball reduction gears, cyclo reduction gears, etc. Since the output characteristics vary depending on the reduction gear, it is important to know the characteristics of the reduction gear when selecting geared motors.