What Is Thread Rolling?

Thread rolling is a plastic-forming process where a strong force is applied to a workpiece, causing deformation. The thread-rolling dies press against the rotating workpiece.

Thread rolling is a plastic-forming process where a strong force is applied to a workpiece, causing deformation. The thread-rolling dies press against the rotating workpiece.

Metals suitable for thread rolling include iron, aluminum, brass, and stainless steel. Materials should have an elongation of 5% or more and a tensile strength of up to 1700 N/mm².

Plastic forming, including thread rolling, is widely used in industrial production. It generally requires less processing time than other methods, resulting in reduced material waste and lower energy consumption. Other forms of plastic forming include extrusion, rolling, pressing, and forging.

Uses of Thread Rolling

Thread rolling, initially developed for producing male threads, creates thread-rolling screws. These screws are stronger than those formed by cutting metal. The process’s high efficiency makes it ideal for mass production.

Various threads can be produced by altering the thread rolling dies. These include metric, trapezoidal, tapered, and specially formed screws.

Besides screw production, the thread-rolling process is also employed in machining parts like gears and worms.

Types of Thread Rolling

The primary methods of thread rolling are flat die, round die, and planetary thread rolling. Each method is outlined below:

- Flat Die Thread Rolling:

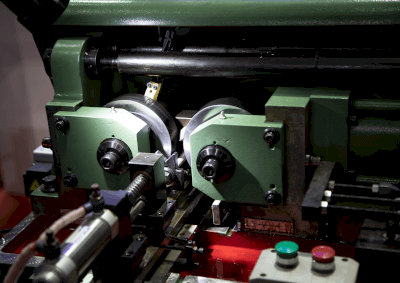

This method involves sandwiching the workpiece between two flat dies, with one fixed and the other moving. It’s highly productive and commonly used for mass-producing general-purpose screws. - Round Die Thread Rolling:

This method uses cylindrical round dies to sandwich the workpiece, rotating in the same direction and speed. It’s versatile and used for metalworking beyond screw production due to adjustable die spacing. - Planetary Thread Rolling:

This method uses an outer arched segment die and an inner round die, with only the round die rotating. It’s highly productive and suitable for high-volume production of general screws.