What Is a Flange Screw?

A threaded flange is a type of threaded joint used in piping, in which the connection method between the flange and the pipe (pipe) is a threaded type.

A Flange Screwed Flange has a female tapered pipe thread on the inside diameter of the flange, and is connected to a pipe end with a male tapered pipe thread by threading it.

The taper pipe thread is defined in JIS B0203 as “a thread whose main purpose is to ensure tightness of the threaded portion when joining piping, piping components, fluid equipment, etc.”.

Applications of Threaded Flange Screws

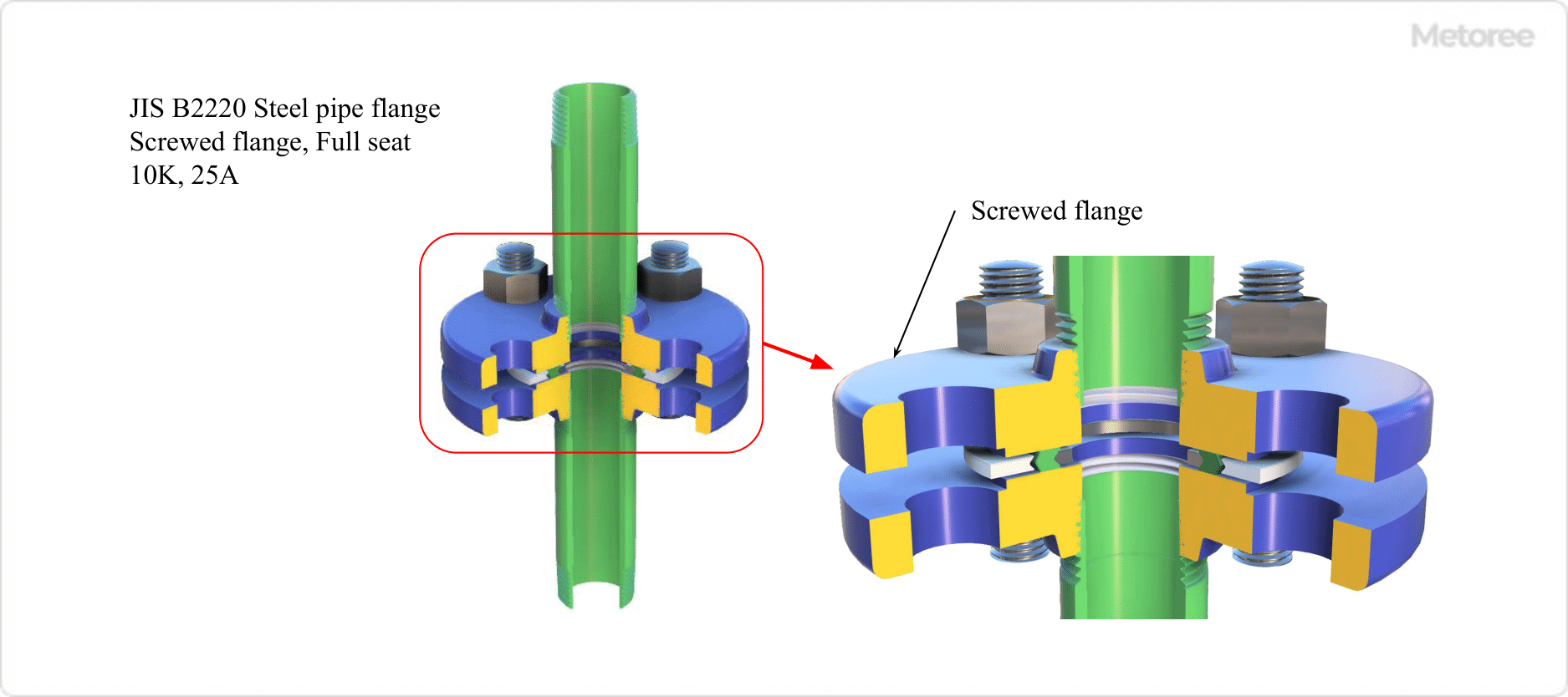

Figure 1. Example of screwed flange use

Flange Screws are used for air piping where the fluid pressure and temperature are not very high and leakage of a certain amount of fluid is not dangerous. Unlike other connection methods (welding, loose joint, etc.), the use of threaded flanges is limited.

When a Flange Screw is used and a leak occurs, it is necessary to remove the pipe, rewrap the sealing tape, and retighten it. In many cases, this type of flange is used when the piping and flange must be easy to install and remove.

In addition, the connection method between the piping and the flange is threaded, which can be used when welding or other fireproofing cannot be used on site. In selecting Flange Screws, the material, pressure resistance, size, etc. are selected based on the type of fluid, pressure, temperature, flow rate, etc.

Principle of Flange Screw

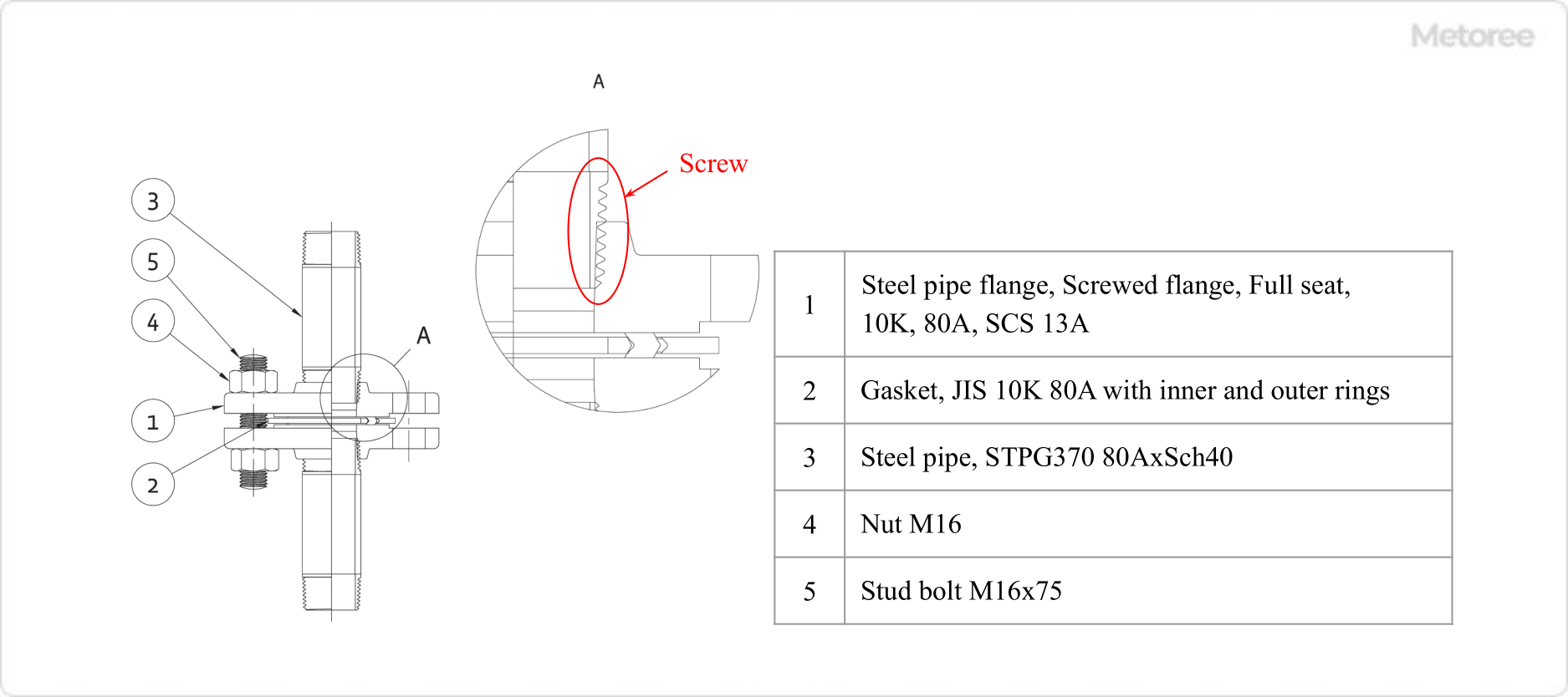

Figure 2. Principle of screwed flange

The principle of a Flange Screw is exactly the same as that of an ordinary piping flange, and the flange surfaces to be connected are sealed by making them adhere to each other.

The screw standards used are as follows

- JIS B0203 Tapered pipe threads

- ASME B1.20.1 Pipe Threads, General Purpose, Inch

Flange Screws are used when the pressure and temperature of the fluid to be used are limited so that leaks are not hazardous in the unlikely event that they occur. When screwing in piping, sealing tape or similar material can be wrapped around the male threads of the piping to improve the sealing performance of the installation.

Flange Screws, like normal pipe flanges, require bolts and nuts for flange fastening to be evenly tightened. Uneven tightening may result in leakage. For this reason, it is common practice to tighten bolts and nuts diagonally, rather than in the order of their sequence.

It is also important to tighten the bolts and nuts at the specified torque value for the gasket material and bolt/nut. Tighten the bolts and nuts in diagonal order, gradually increasing the tightening torque until the required tightening torque value is reached. When used with high-temperature fluid, the tightening of the threads may loosen due to thermal expansion after the actual flow of high-temperature fluid, in which case the bolts and nuts need to be retightened.

Types of Threaded Flange Screws

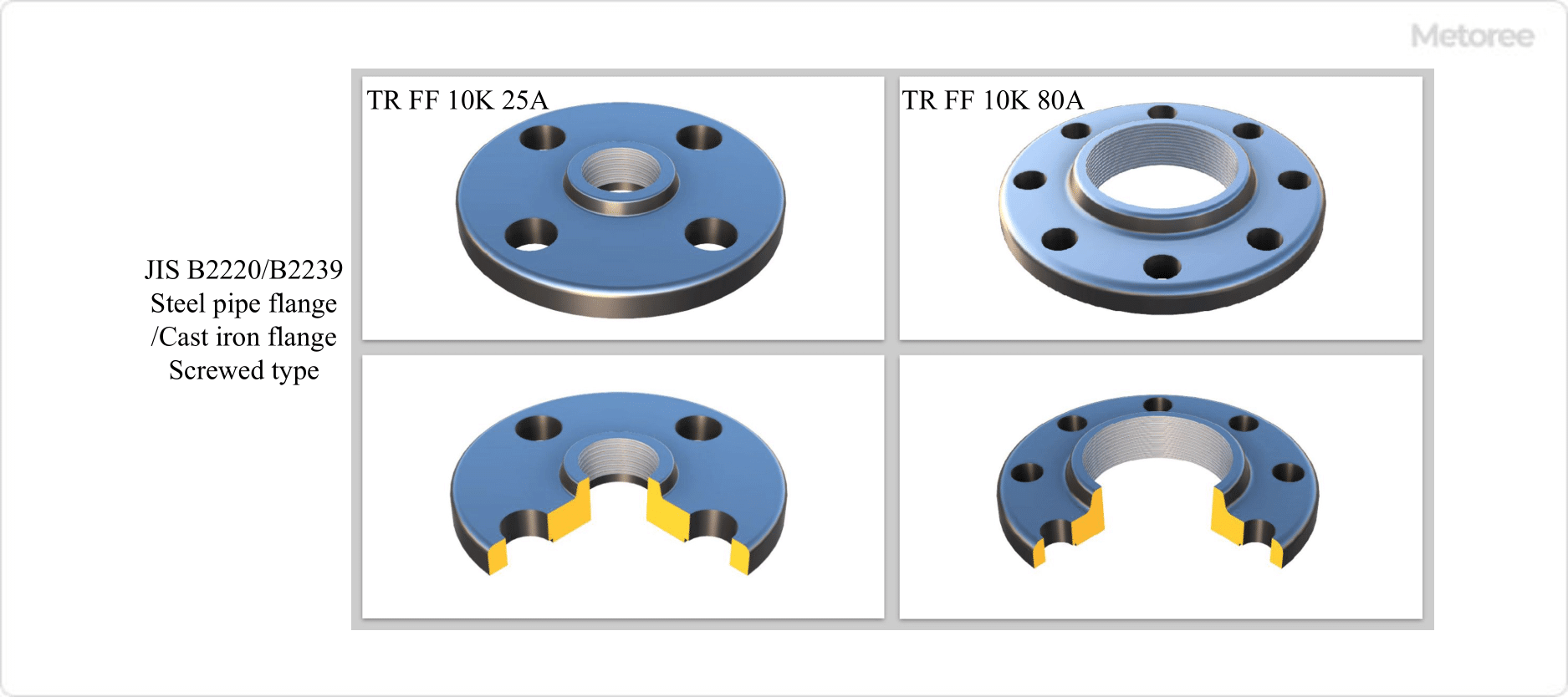

Figure 3. Example of JIS B2220/B2239 screwed flange

1. Classification by Standard

There are various standards for flanges, such as JIS, JPI, ASME/ANSI, etc. Typical examples are as follows.

- JIS B2220 Steel pipe flanges

- JIS B2239 cast iron flange

- JPI-7S-15-2011 Flanges for petroleum industry

- ASME/ANSI B16.5 Pipe Flange and Flanged Fittings

In “JIS B2220 Steel Pipe Flanges,” nominal pressure ranges from 5K to 63K, but Flange Screws are applied to nominal pressures of 5K, 10K, 16K, and 20K. In “JPI-7S-15-2011 Flanges for the Petroleum Industry” and “ASME/ANSI B16.5 Pipe Flange and Flanged Fittings”, the flanges are applied to nominal pressure classes 150, 300, 600, 900, 1500 and 2500.

The following is an example of JIS standard flange specifications.

- JIS B 2220 TR FF 10K 80A SCS 13A

- Steel Pipe Flange, Threaded Flange, Full face, 10K, 80A, SCS 13A

2. Classification by Material

Typical flange materials in JIS standards are as follows

- Rolled material: JIS G3101 SS400, G4051 S20C/S25C

ASTM A515 70, A516 70 - Forging: JIS G3201 SF390A/SF40A, G3202 SFVC1

ASTM A105, A350 LF2 - Casting material: JIS G5101 SC410/SC480, G5151 SCPH1

ASTM A216 WCB

Low Alloy Steel

- Rolled: ASTM A201 A/B, A387 11 CL2

- Forging: JIS G3202 SFVC2A, G3203 SFVAF1/SFVAF11A

ASTM A182 F1/F11 CL2/F12 CL2 - Casting material:JIS G5151 SCPH2/SCPH11/SCPH21

ASTM A217 WC1/WC6, A352 LC1

- Rolled materials:JIS G4304/4305 SUS304/SUS304L/SUS316/SUS316L

ASTM A240 304/304H/304L/316/316H/316L/317 - Forging: JIS G3214 SUSF304/SUSF304L/SUSF316/SUSF316L

ASTM A182 304/304H/304L/316/316H/316L - Casting materials:JIS G5121 SCS13A/SCS14A/SCS16A/SCS19A

ASTM A351 CF3/CF3M/CF8/CF8M/CG8M

Flanges are used in pairs, and both flanges must be made of the same material. The selection of flange material is indicated in each standard; in the JIS standard, “nominal pressure” and “material group number” are selected according to the “maximum working pressure” and “fluid temperature” of the working fluid flowing in the pipe.

It is important to select materials from several standard materials classified by material group number according to the flange manufacturing method, operating environment, cost, and other factors.