What Is a Bearing?

A bearing is a mechanical component that supports a rotating body, such as a shaft, accurately and smoothly. When a shaft is rotated, resistance force and frictional heat are always generated. This is due to friction between the shaft and the supporting structure or support, resulting in a loss of rotational energy. Bearing is used to prevent the loss of energy and heat generated by friction.

There are two types of bearing, rolling bearing, and plain bearing, depending on their structure. The difference is that rolling bearing uses rolling elements and plain bearing uses an oil film.

There are also two types of bearing, radial bearing, and thrust bearing, depending on the direction of load applied to the bearing.

Radial bearings are used when the load is applied to the bearing in the direction of the shaft centerline.

Thrust bearings are used when the load is applied to the bearing in the direction perpendicular to the centerline of the shaft.

Uses of Bearings

Bearings are widely used in a variety of products, including machinery that rotates industrial shafts, automobiles, aircraft, railcars, and home appliances in our daily lives.

Familiar examples include cars and motorcycles, which use more than 100 bearings of various sizes. In particular, bearings are indispensable for engines, which have many rotating parts to reduce energy loss.

Bearings are used for two main purposes:

1. To support rotation and maintain the exact position of the shaft.

2. To reduce friction caused by rotation and maintain smooth rotation.

Bearings are used in so many other situations that it is difficult to list them all. Today, it is difficult to imagine a world without bearings, and they contribute greatly to reducing the consumption of oil and other resources due to the energy loss caused by friction.

Types and Characteristics of Bearings

The structure and features of each type of bearing are described below. There are two types of bearings: radial bearings and thrust bearings, depending on the direction in which the load is applied. Each type of bearing has self-aligning bearings, which are used when there is some deflection of the shaft.

1. Rolling Bearings

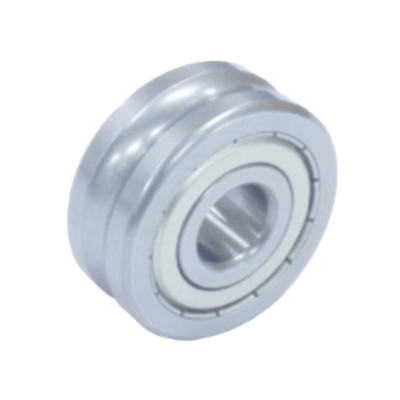

Typical rolling bearings consist of an inner ring in contact with the shaft, rolling elements such as balls and rollers, a cage to hold the rolling elements, and an outer ring in contact with the outer housing. There are two types of rolling bearings: ball bearings and roller bearings.

1) Ball Bearings

This type of bearings uses spherical balls as rolling elements. They are used as bearings for relatively high speeds and low loads. There are several types of ball bearings with different structures and usage methods, such as deep groove ball bearings, angular contact ball bearings, spherical ball bearings, and thrust ball bearings.

2) Roller Bearings

This type of bearings uses cylindrical, tapered, or needle rollers as rolling elements. They are used as bearings for relatively large loads. There are several types of roller bearings with different structures and methods of use: cylindrical roller bearings, tapered roller bearings, spherical roller bearings, and thrust spherical roller bearings.

3) Needle Bearings

This is a type of roller bearing characterized by needle-like thin rollers. There are two types of needle bearings: radial bearings and thrust bearings.

2. Sliding Bearings

Sliding bearings do not have rolling elements such as balls or rollers in the bearings. They are manufactured by cylindrically processing oil-impregnated metal or resin with low frictional resistance. They are generally called “metal” or “bushing“. There are two types of bushings depending on the shape: “metal, bushing (flat bearings)” and “flange metal, flange bushing (flat-flange bearings)”.

Rolling bearings are used for small to medium loads and are periodically replaced as consumable parts. Except for types that are pre-filled with grease (lubricant), the oil (lubricant) used in the bearings must be checked and replaced periodically for proper management.

When bearings are mounted on a shaft, depending on the fit with the shaft (difference in the fixing directness due to the size of the clearance between the bearings and the shaft or housing), the bearings must be heated and hardened before mounting on the shaft.

Sliding bearings are used for heavy loads and can be used permanently if the operating environment and maintenance are good since there is no metal contact between the bearings and the shaft due to the oil film. However, they should be replaced when worn or damaged.