What Is a Shaft Coupling?

A shaft coupling, also known as a coupling or joint, is a general term for components that connect two shafts.

Shaft couplings primarily connect the machine side (driven side) to the motor, smoothly transmitting the driving force.

Among various types, flexible shaft couplings are commonly used to absorb vibrations by allowing for shaft misalignment. This flexibility reduces the load on bearings and absorbs shocks and vibrations from the machinery.

Applications of Shaft Couplings

Shaft couplings are widely used in machinery that involves drive and driven transmission mechanisms. For instance, in rotating machines like pumps, blowers, and agitators, shaft couplings connect the motor (drive side) to the impeller shaft (driven side) for power transmission.

1. Flexible Shaft Couplings

These are suitable for machinery prone to misalignment or that generates significant vibrations, with a bush between the flange and bolt to absorb vibrations.

2. Fixed Shaft Couplings

Often utilized in machinery requiring a high transmission capacity.

Principle of Shaft Couplings

Rotational power is transmitted by securing the drive and driven shafts with mounting joints using bolts. Methods of securing the shaft and coupling include key material and set bolts or shrink fitting.

1. Flexible Shaft Couplings

A bush made of rubber or similar material is inserted at each fixing point with a bolt, absorbing shaft runout, vibration, and misalignment while smoothly transmitting power. Regular inspection and replacement are crucial as cracks from aging can reduce flexibility and vibration absorption.

2. Fixed Shaft Couplings

These are bolted into place and require precise centering to prevent misalignment. Without a bushing, they provide lossless power transmission, ideal for situations requiring the transmission of large amounts of power.

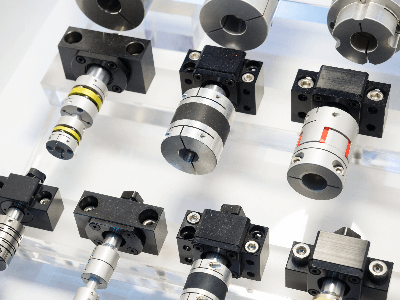

Types of Shaft Couplings

Beyond flexible and fixed shaft couplings, there are additional types, such as universal and Oldham shaft couplings. Selection should match the equipment’s specifications.

1. Flexible Shaft Couplings

Commonly used structures include muff and flange types. Muff couplings cover the shafts’ outer periphery with a cylindrical boss, while flange types are connected by inserting flanges into both shaft ends and securing them with reamer bolts.

2. Fixed Shaft Couplings

Varieties include flange type, laminated leaf spring, chain, gear type, and rubber shaft couplings, each serving different requirements.

3. Universal Couplings

Appropriate when connecting axes have significant misalignment or intersect, available in constant and non-constant velocity types.

4. Oldham Shaft Couplings

Suitable for parallel axes with minor misalignment between them.

Structure of Shaft Couplings

With a multitude of types, including rigid, metal slit, metal coil spring, magnet, pin/bush, disc, high damping performance laminated rubber, jaw, and resin bellows types, selection depends on the application and characteristics.

How to Choose a Shaft Coupling

1. Flange Type Flexible Shaft Couplings

A commonly used structure where a rubber bush on one bolt end connects the flanges on both shaft ends, transmitting torque through compressive strength. Its flexibility accommodates shaft center deviations.

2. Laminated Leaf Spring Shaft Couplings

Connects joint flanges with a laminated leaf spring to transmit torque, accommodating misalignment and angular misalignment thanks to its flexibility.

3. Chain Shaft Couplings

Two hubs on the axes to be connected are fitted with sprockets of the same tooth count and connected by a chain, offering limited flexibility.

4. Gear Type Shaft Couplings

Internal teeth on the inner cylinder mesh with external teeth on the boss part’s external cylinder, transmitting large torque.

5. Rubber Shaft Couplings

Entirely made of rubber, compared to flange-type flexible shaft couplings, these accommodate misalignments in all directions thanks to the rubber elastic body.