What Is a Hydraulic Vise?

A hydraulic vise is a tool that uses the power of hydraulic pressure to strongly secure an object.

The distance between two vises can be adjusted externally by turning a handle, and the strength of the vise to hold the object changes according to the distance between the two vices.

Because it uses hydraulic pressure, it can achieve tightening precision which is difficult to achieve with manual clamping alone, and it can be strongly secured with little force.

When the clamping force is strong, one side of the clamp may lift up, causing the object to move.

To prevent this phenomenon, a hydraulic vise with an anti-lift mechanism is used.

Uses of Hydraulic Vises

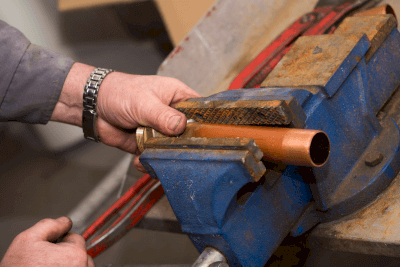

Hydraulic vises are used for metal or wood processing where the material needs to be strongly secured.

This includes cutting, welding, or grinding of the material to be secured.

Although a normal manual vise can be used, it is necessary to avoid moving the position of the vise when a heavier material needs to be secured more strongly or when machining accuracy is required.

In such situations, hydraulic vises are used to secure the material.

Principle of Hydraulic Vises

A vise is a tool that holds an object between two metal plates and fixes it strongly in place.

Hydraulic vises are vises that use the power of hydraulic pressure and can clamp materials with light force. Usually, the handle is turned from the outside, and the tightening strength can be adjusted according to the amount of rotation.

This method is based on a hydraulic pressure-generating mechanism based on Pascal’s principle.

If a liquid is enclosed in a container and pressure is applied to the liquid from one side, the pressure propagates uniformly through the container.

Since the larger the area of pressure, the greater the force, even if a piston with a small area is pushed in, a large force can be applied in a large area at output.

There are two types of hydraulic pressure propagators: the “built-in hydraulic pressure type” in which oil is held inside, and the “external supply type” in which oil is injected externally.

The built-in hydraulic type has the advantage that it does not require hydraulic adjustment and can be used immediately.

On the other hand, the externally supplied type is selected when the hydraulic mechanism is not required to work or when the strength of the hydraulic pressure needs to be adjusted.