What Is a Tube Bender?

A tube bender is a tool or machine designed for bending pipes and tubes, offering precision and efficiency in various industrial and construction applications. These devices enable accurate bending, catering to the specific needs of industries such as aerospace, automotive, and construction, where precise dimensions and angles are critical. Tube benders can handle materials like steel, stainless steel, and aluminum, particularly suitable for thin-walled tubes, with options available for thicker walls, such as hydraulic benders.

Uses of Tube Benders

Tube benders are versatile tools used across numerous settings, from infrastructure projects for laying water and gas pipelines to the manufacturing sector for creating automotive parts like exhaust pipes and fuel lines. Their ability to produce precise bends makes them invaluable in ensuring the functionality and safety of various systems and components.

Principle of Tube Benders

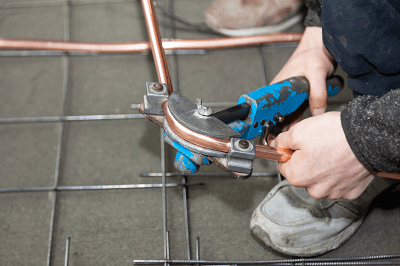

The operation of tube benders involves dies, pie bar handles, and frames. Dies, tailored to the pipe’s diameter, shape the tube as the operator manipulates the pie bar handle, engaging the bending process. The sturdy frame supports the mechanism, ensuring stability during bending. Advanced models might incorporate electric or hydraulic systems for enhanced precision and ease of use.

How to Select Tube Benders

Choosing the right tube bender involves considering the driving source — manual, electric, hydraulic — the applicable tube diameter, and the material compatibility. It’s crucial to select a bender that matches the project’s specific requirements, including the type of material being bent and the desired bending capacity, to ensure efficient and accurate bending.