What Is a Rivet Nut?

A rivet nut, also known as a blind nut, is a fastener that creates a screw hole in thin materials like steel plates. It is designed for situations where it’s not feasible to cut a screw hole directly due to the thinness of the material. Rivet nuts, resembling screws with internal threads, are inserted into pre-drilled holes in the thin steel plates, creating a secure point for fastening screws.

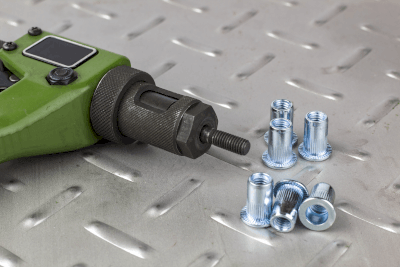

To use a rivet nut, a special tool called a hand nutter is required for the riveting process.

Uses of Rivet Nuts

Rivet nuts are primarily used for attaching objects to thin plates using screws. They offer a practical solution in situations where accessing the back of the plate to fasten a nut is difficult, or when simplicity and ease of installation are preferred. This makes them particularly useful in applications like appliance covers and automotive manufacturing, where thin plates are commonly used.

Principle of Rivet Nuts

Rivet nuts are typically made of stainless steel. However, due to the hardness of stainless steel, aluminum rivet nuts are often preferred for hand nutter applications. For stainless steel rivet nuts, or those larger than M6, pneumatic or hydraulic riveting equipment is usually necessary due to the increased difficulty of manual installation.

During installation, the rivet nut is first attached to the mandrel of the hand nutter. The hand nutter then inserts the rivet nut into the pre-drilled hole in the thin plate. By pulling the handle of the hand nutter, the rivet nut is tightened, causing it to flatten against the inside of the plate, thereby securing both the plate and the rivet nut’s brim. This process requires considerable force and may, in extreme cases, lead to the breaking of the mandrel.