What Is a Crank Handle?

A crank handle is a mechanical input device that generates rotational output by manually rotating a handle. It typically consists of a lever (rod-shaped part) with a hole or shaft at one end, serving as the rotary output side, and a handle mounted in an L-shape for input.

A crank is a part of an axle or curved shaft, or an arm, keyed at right angles to the end of a shaft, converting reciprocating motion to circular motion or vice versa.

Uses of Crank Handles

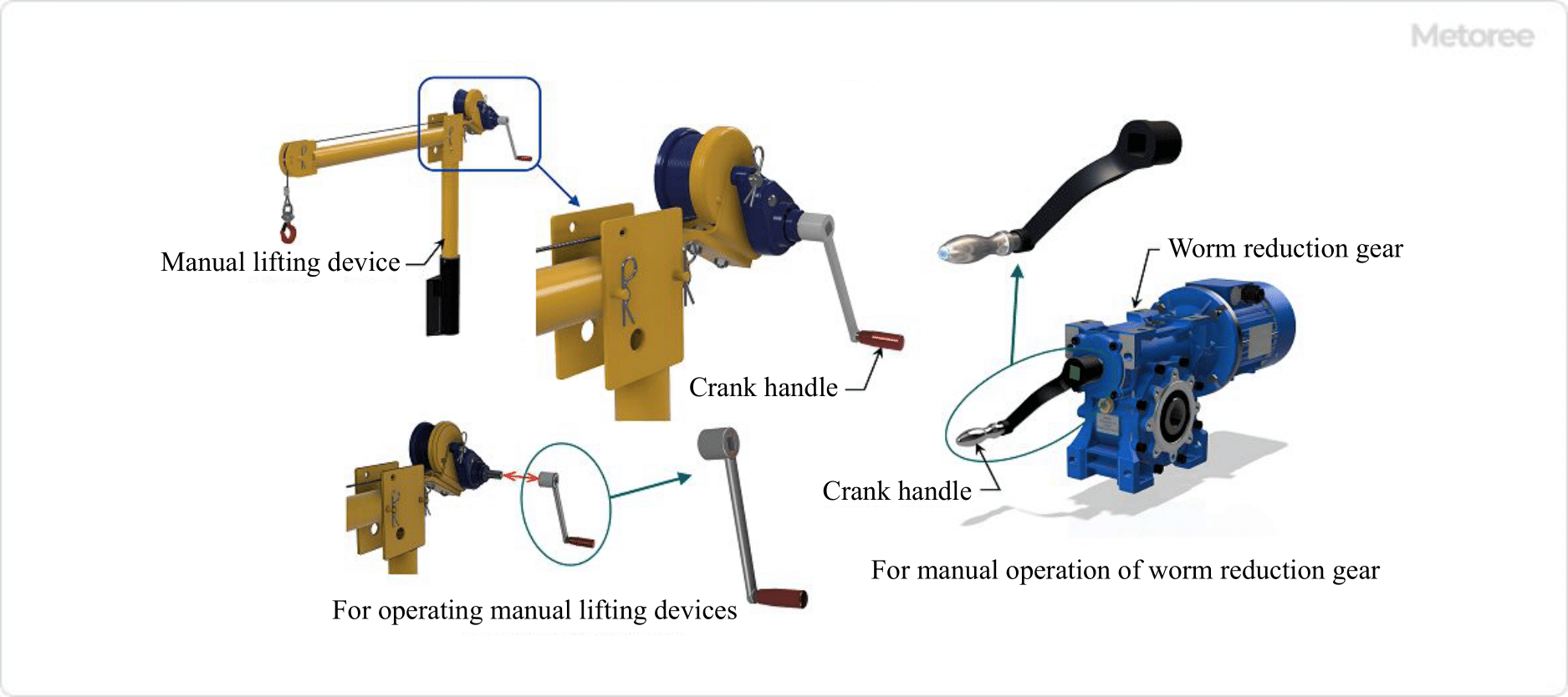

Figure 1. Example of crank handle use

Crank handles are used in various applications requiring rotary motion. Common examples include handles for car jacks, window and louver openers, and fishing rod reels. In industrial settings, they are used for manual operations of valves, electric motors, gears, and machine tool positioning like lathes.

Figure 1 illustrates crank handles used for the manual operation of lifting devices and worm reduction gears.

Principle of Crank Handles

Crank handles function as mechanical input devices for manual rotary movements, consisting of a lever connecting a rotating shaft to an off-center shaft. They generate rotational output through manual rotation, offering leverage to reduce the required force.

The force needed to rotate a shaft, or torque, is calculated as follows:

Torque T(N-m) = Tangential force F(N) × Turning radius R(m)

The longer the lever, the more rotational force can be generated with less effort. However, longer levers make increasing rotational speed more difficult. Thus, lever length should be selected based on the required torque and rotational speed.

Types of Crank Handles

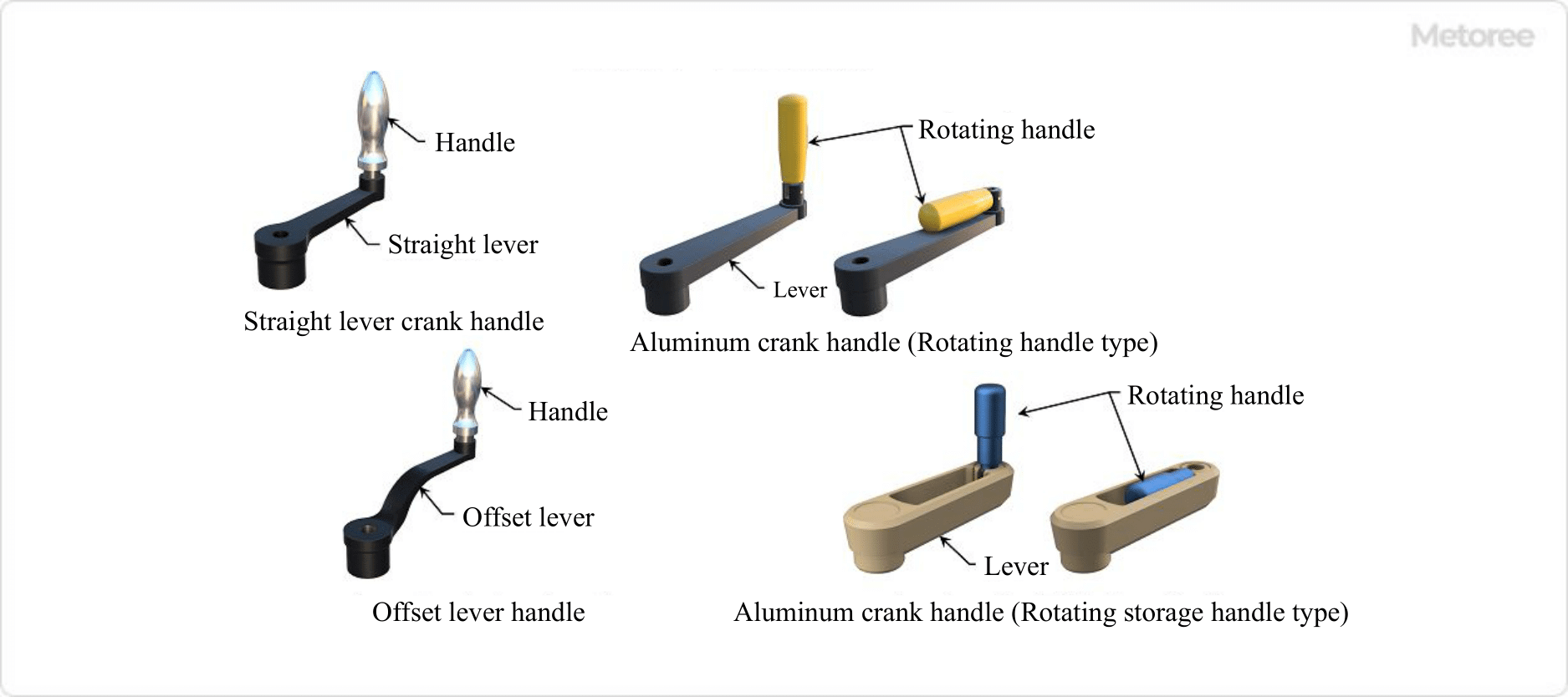

Figure 2. Types of crank handles (1)

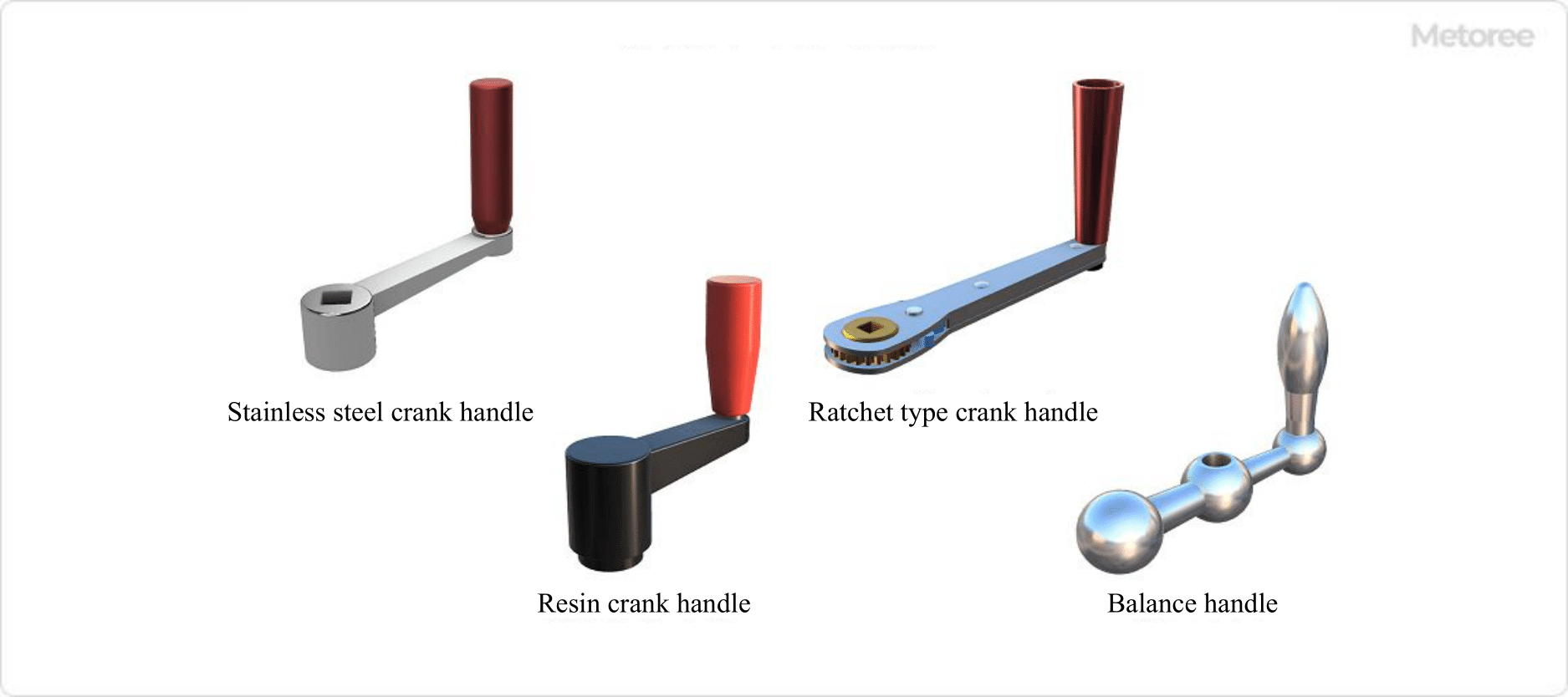

Figure 3. Types of crank handles (2)

- Lever/Handle Material: Cast iron, carbon steel, stainless steel, aluminum alloy, resin

- Lever shape: Straight, offset

- Handle mounting: Fixed, rotating, rotating retractable

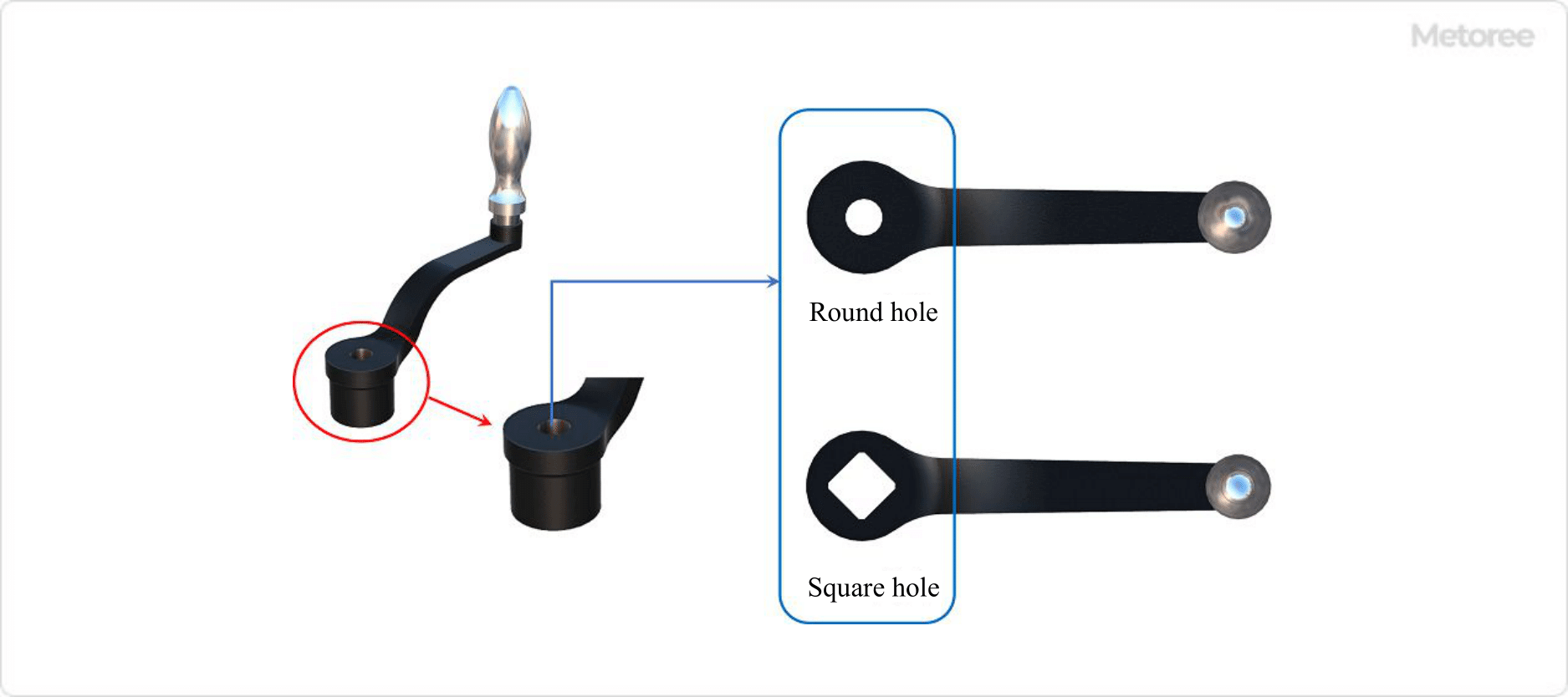

- Lever hole shape: Round hole, square hole

- Others: Ratchet shaft attachments, balance weight on opposite sides of the handle

Figure 4. Types of crank handles (3)

Crank Handles Selection

When selecting crank handles, consider the operating environment and workspace. Factors include the shaft shape, required operation force, material strength, handle accessibility, environmental conditions, and workspace limitations.

- Select a round or square hole according to the shaft shape.

- Choose the appropriate shaft and lever hole dimensions for the equipment.

- For operations requiring more force, opt for a longer lever.

- If high strength is needed, consider materials like carbon steel or stainless steel.

- Choose an offset handle to avoid interference with nearby equipment.

- Select a rotary or retractable handle if space is limited.

- For harsh environments, choose durable, weather-resistant materials.

- Consider a ratchet-type handle for a limited workspace.

- For tasks requiring many rotations, like lathe positioning, select a balanced handle.