What Is an Angular Double-Row Ball Bearing?

Angular double-row ball bearings are a specialized type of angular contact ball bearing with two rows of balls. They are designed to support both radial and thrust loads, excelling in high-speed rotation and heavy load conditions. Unlike single-row bearings which support only radial loads, double-row bearings offer enhanced support and stability.

Applications of Angular Double-Row Ball Bearings

Angular double-row ball bearings support loads in both radial and axial directions and can be used in a wide variety of applications. Examples include aircraft landing gears and railroad bogies.

Other examples include power systems for industrial printers and industrial machinery. The illustration below shows a case in which angular double-row ball bearings are used to support radial and thrust loads from the roller side in part of a film product feed mechanism in a production facility.

Principle of Angular Double-Row Ball Bearing

These bearings have a contact angle that enables them to support thrust loads in both directions, in addition to the capabilities of single-row bearings. The assembly involves setting one ring (inner or outer) fixed while moving the unfixed side towards the shaft’s center, creating axial internal clearance. They offer improved stability and durability due to load distribution and have a more compact design compared to single-row combinations.

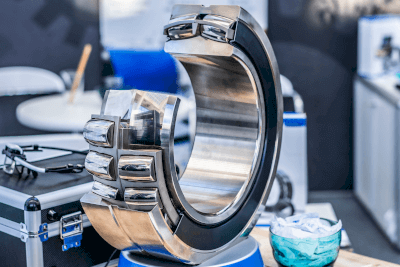

Structure of Angular Double-Row Ball Bearing

Angular double-row ball bearings consist of an inner ring, outer ring, balls, and retainers. There are open types without a sealed structure, shielded types with a sealed structure, and sealed types (non-contact and contact), which are selected according to the application and environment.

The purpose of the sealed structure is to prevent leakage of grease filled in the ball section and ingress of dust and moisture from the outside.

|

Types of Seals |

Sealing device |

Dust resistance |

Lubrication method | Friction resistance |

|

Open type |

None |

Low |

Externally supplied grease, splash or oil bath lubrication |

Low |

|

Shielded type |

Metal shield plate |

Somewhat high |

Grease sealed in bearing |

Low |

|

Non-contact seal type |

Adhesive seal plate of steel plate and synthetic rubber |

Higher than sealed type |

Low |

|

|

Contact seal type |

Highest |

Slightly higher |

Other Information on Angular Double-Row Ball Bearings

1. Preload

Preload in bearings improves shaft rigidity, and accuracy, reduces ball slip, vibration, and noise, and prevents fretting from external vibrations. There are two preload methods: fixed-position with a spacer and constant-pressure with a spring.

2. Standards

Relevant standards include JIS B1522, DIN 628-3, and ISO 15, covering angular contact ball bearings specifications and dimensions.