What Is Jig Grinding?

A jig grinding tool is a tool used for cutting, drilling, and other machining operations. It is essential for holding the workpiece firmly during machining or guiding the cutting position.

The purpose of jig grinding is to improve processing quality, achieve uniform processing among different operators, and enhance productivity by increasing efficiency in operations.

Uses of Jig Grinding

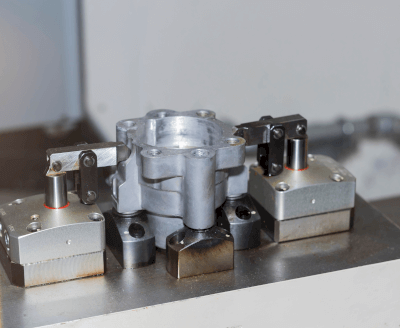

Devices like vices, commonly employed in jig grinding, secure workpieces during cutting and drilling. For shaping materials such as sponge or plastic, jig grinding guides the cutter along a tool matching the workpiece shape, ensuring uniform processing and allowing anyone to easily and quickly work on the piece. The increasing automation in machining has led to more widespread use of jig grinding machines, including industrial robots for efficient loading and unloading of workpieces.

Principles of Jig Grinding

Jig grinding encompasses a variety of tools, from high-end and expensive models to simple and affordable jigs like those used for cutting tape. These tools are not only for holding objects but also for precise positioning and quick fixing. Modern robot-based jig grinding systems incorporate various functions to boost productivity. They may use vision cameras for workpiece inspection, input necessary machining operations, and visually inspect parts post-machining. Robots equipped with force sensors, 3D vision cameras, and artificial intelligence can perform repetitive tasks with high accuracy, handling heavy workpieces and tasks that are challenging for humans.