What Is a Measuring Light Curtain?

A measuring light curtain is a safety sensor that detects when a person or object enters the hazardous area of a machine or equipment.

They are sometimes also referred to as light grids. Light curtains are installed at entrances and exits of machinery without doors to provide time for the light to stop when it detects that the light beam has been interrupted. This happens at a distance where no person or object is in contact with the hazardous area.

Since the size of the smallest detectable object varies from device to device, it is crucial to select the appropriate one based on the size of the object to be blocked, the safety distance, and the installation site’s height. Measuring light curtains typically use LEDs that emit infrared rays with a wavelength of about 900 nm, as the specified light source falls in the 400 nm to 1,500 nm wavelength range.

Uses of Measuring Light Curtains

Measuring light curtains are commonly employed to enhance safety in manufacturing facilities with automated production processes, including metal processing, pharmaceuticals, food production, packaging, semiconductor manufacturing, transportation, and automotive industries.

When partitions or doors cannot be installed in hazardous operational areas, such as automated assembly machines, mounting machines, packaging equipment, printing machines, and line conveyor systems, they serve to monitor for the intrusion of workers’ hands, fingers, arms, legs, other body parts, and obstructions.

Principles of Measuring Light Curtains

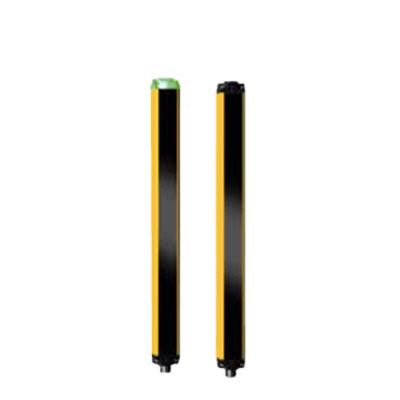

Measuring light curtains consist of a floodlight and a receiver, installed as a set. The floodlight contains aligned projection elements, and the receiver also features aligned projection elements. They are positioned in parallel, allowing multiple parallel light beams emitted from the projector side to be received on the receiver side.

When the receiver side successfully receives all of the multiple beams emitted by the projector side, it is considered normal, and the machine or equipment’s operation is allowed. If any part of the light path is blocked due to an intrusion, such as a worker’s hand or leg, the system recognizes the situation as dangerous and halts the machine or equipment’s operation.

The light curtain also includes a muting function, which differentiates between a workpiece passing through the detection area and a human body entering the detection area. It also has a blanking function, enabling the disabling of a specific portion of the detection area.

How to Select Measuring Light Curtains

A wide variety of measuring light curtains are available from different manufacturers. To make the best selection, consider the following points:

1. Measuring Light Curtain Length

The length of the main body of measuring light curtains should be suitable for the actual production site where they will be used. If it is too short, it may fail to detect if any part of a worker’s body enters the hazardous area, potentially leading to accidents. Conversely, if it is too long, installation may become impractical.

2. Water and Oil Resistance

Production sites often involve dust and other particles. If these particles adhere to the projector and receiver surfaces of measuring light curtains, the light receiver may fail to detect the projector’s light properly, resulting in false danger alerts. Therefore, opting for water-resistant curtains simplifies maintenance.

3. Synchronization Method

Measuring light curtains rely on synchronized timing between the light emitted by the projector and the light received by the receiver to ensure safe monitoring. Two synchronization methods exist: wired synchronization, where the projector and receiver are connected by a synchronization wire, and optical synchronization, where they are connected optically by a synchronization wire.

Optical synchronization involves less wiring and is easier to manage, but generally, it is limited to a smaller number of light curtains to prevent false detection (interference) caused by light projectors from different measuring light curtains.

4. Ease of Optical Axis Alignment

Measuring light curtains require the receiver to capture all the multiple lights emitted by the floodlight. This necessitates adjusting the position and angle of the projector and receiver, known as optical axis alignment. Additionally, it is important to check whether the curtain provides clear indications of which part of the receiver receives specific amounts of light and whether it is resistant to torsion, among other factors.