What Is a Micrometer Head?

A micrometer head is the part of the micrometer that moves and touches the object to be measured when the micrometer pinches the object. Typically, the head is moved by rotating a knob on the head part to pinch the object to be measured. In addition to being able to measure visually, many digital micrometer heads are now on the market. The tip is usually cylindrical, but there are also conical, spherical, flange-shaped, and other products.

Uses of Micrometer Heads

Micrometer heads are used for inspecting and maintaining industrial equipment and products and for dimensional measurement of test objects in laboratories and research laboratories. They are used for products that require higher precision measurements than those made with calipers, etc. When selecting a micrometer head, it is necessary to consider measurement accuracy, ease of error, whether it is a digital or analog type, and ease of maintenance. Note that micrometer heads measure by contact and are not suitable for measuring rubber and other materials whose shape is deformed by contact.

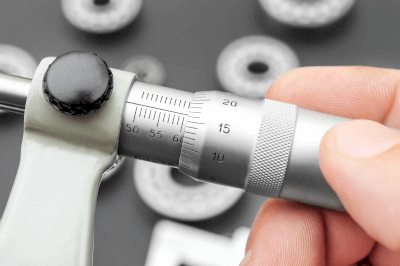

Principles of Micrometer Heads

The features of the micrometer heads are described below. The micrometer heads consist of a measuring section, spindle, mounting section, graduated sleeve, coarse knob, and fine knob. The rough and fine knobs are connected to the spindle by a gear, which causes the spindle to move following the rotation of the knob. Generally, the fine control knob is also equipped with a scale, enabling measurement of even finer amounts. In the mounting area, products are available with mounting methods such as tightening using screws, nuts, or mortises.

When taking a reading, the spindle moves the coarse knob to contact the object to be measured lightly. Then, by adjusting the fine control knob, the spindle is brought into complete contact with the object to be measured. The fine adjustment knob is a mechanism that prevents the spindle from advancing after making contact, allowing it to rotate until it makes complete contact. The measurement can then be made by examining the scale on the sleeve and the scale on the fine control knob.

Examples of Micrometer Heads Use

The micrometer heads are used for adjusting the movable range of multi-axis stages, etc., and for inspecting jigs for large quantities of parts that need to be inspected.

Micrometer Heads Clamp

The micrometer heads can be used as a clamp by using a stopper that matches the range of motion. Selecting a product with a clamp is also recommended depending on the product. Choosing a product with a clamp will prevent the loosening of the operation.

How to Fix the Micrometer Heads

The method of fixing the micrometer heads depends on whether the micrometer head mounting stem is a straight type or a nut type.

- How to fix a straight type: Use a split part on the bearing side and clamp it to the mounting shaft with a screw or the like. Pass the mounting shaft through the hole in the bearing side and fix it with a set screw.

- Fixing method for types with nuts: Pass the mounting shaft through the hole on the bearing side and secure with the nut attached.

Load Capacity of Micrometer Heads

The load capacity of micrometer heads varies depending on the conditions of use, such as mounting method, static load, or dynamic load, and whether the micrometer heads are used in operation or as a stopper. Therefore, there is no quantitative definition.

As an example, recommended load capacity limits are listed below.

Load capacity of micrometer heads

- Standard type (spindle pitch 0.5 mm): up to about 4 kg

- High-performance type spindle pitch 0.1 mm/0.25 mm: up to approx. 2 kg

- High-performance type spindle pitch 0.5 mm: up to approx. 4 kg

- High-performance type, spindle pitch 1.0 mm: up to approx. 6 kg

- High-function type Spindle pitch linear type: up to approx. 2 kg

- High-function type MHF for ultra-fine adjustment (with differential mechanism): up to approx. 2 kg

Static load by mounting method

- Tightening nut method: 8.63 to 9.8 kN (880 to 1000 kgf) or main unit breakage

- Slit-split fastening method: 0.69 to 0.98 kN (70 to 100 kgf) for falling off from the mounting bracket

- Screw fixing method: Damage to set screw at 0.69 to 1.08 kN (70 to 110 kgf)