What Is a Pump Piston?

A pump piston is a device that supplies and transfers liquids and gases through the reciprocating motion of a piston.

The pump piston moves liquid or gas by utilizing the volume change that occurs when the cylindrical piston moves in a linear reciprocating motion inside the cylinder of the pump housing. The simplest pump piston, a combination of a piston and two valves, has long been used for wells and other applications. Due to their high discharge pressure characteristics, they are also widely used in industrial fields.

Pump pistons are considered positive displacement pumps. This category includes gear, vane, screw, scroll, plunger, and diaphragm pumps.

Uses of Pump Pistons

Pump pistons are relatively simple in construction and easy to handle. They have long been used for tasks such as manual well pumps and kerosene pumps. Some specific uses of pump pistons include:

- Drainage systems in industrial production lines, transfer systems for highly viscous liquids, water, sewage lines, high-pressure gas lines, etc.

- Transfer and precise filling of food oils and materials, cosmetics, medicines, reagents, electrolytes, shampoos, conditioners, additives, fragrances, etc.

- Hydraulic pumps for construction vehicles, steel, shipbuilding, machine tools, industrial machinery, etc.

- Conveying sewage dehydration cake, sewage dehydration sludge containing foreign matter, coal slurry, etc.

Principles of Pump Pistons

The basic operating principle remains consistent for all pumps: liquids or gases are transferred through repeated suction and discharge actions. Pump pistons incorporate valves at the inlet and discharge ports to prevent backflow and apply pressure.

The capacity of a pump piston is determined by three factors: piston diameter, stroke, and the number of pistons. The flow rate is determined by the number of revolutions. Pump characteristics are represented in a chart with flow rate on the horizontal axis and pressure on the vertical axis. Pump pistons designed for liquid applications exhibit minimal pressure variation concerning flow rate.

Among pump pistons, axial and radial types offer continuous capacity adjustment. Even when the required capacity changes, it can be adjusted without altering the rotation speed, simplifying control and conserving energy.

Features of Pump Pistons

- Capable of Handling High Pressure

Pump pistons exhibit superior pressure resistance compared to other pumps and can withstand pressures of up to 50 MPa. They also demonstrate high efficiency.

- Adaptability to Variable Displacement

Axial and radial pump pistons can be easily adapted for use in variable displacement pumps.

- Use as a Motor

Axial and radial pistons can function as motors because their design is fundamentally similar to that of pumps. These pistons and motors can be connected to transmit power.

Types of Pump Pistons

Pump pistons are broadly categorized into axial, radial, and reciprocating types.

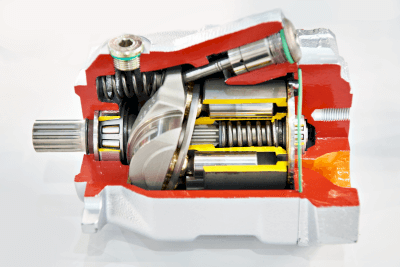

- Axial Type

Pistons in axial pumps are arranged close to the drive shaft. They are divided into two types: axial and swash plate, based on the method of piston reciprocation. This structure can also be employed in motors, making it the most commonly used positive displacement pump.

Axial pump pistons can be converted into variable displacement pumps by adjusting the swash shaft or swash plate angle, thereby varying the piston’s displacement from zero to maximum continuously.

- Radial Type

In radial pumps, multiple pistons are arranged radially around the drive shaft. Eccentric cam rings or cams drive the pistons. In eccentric radial pumps that use an eccentric cam ring, the pistons reciprocate, and the entire cylinder block rotates. This type can also be used as a motor.

Eccentric radial pumps can be adjusted for variable displacement by altering the eccentricity of the cam ring, providing excellent responsiveness.

- Reciprocating Type

Reciprocating pistons are driven by a crankshaft or cam. There are various configurations, including single, double, and multiple pistons. Valves at the inlet and discharge ports make them unsuitable for motor applications. Despite their larger size and weight, they can handle relatively high pressures compared to other methods.