What Is Radial Drilling Machinery?

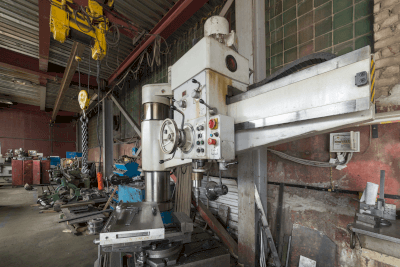

Radial drilling machinery is a type of drilling machine used for machining workpieces.

The table is positioned away from the center of the machine, and the tool can move radially. This machinery is suitable for machining large workpieces and offers high precision.

Specialized attachments and tools can machine complex shapes, but they generally offer less precision than other equipment. Therefore, it’s important to select suitable equipment based on the workpiece’s shape and material.

Uses of Radial Drilling Machinery

Radial drilling machinery is commonly used for:

- Drilling: Automotive frames, engine parts, etc.

- Reaming and Tapping: Engine cylinder heads and bolt holes.

- Grinding and Polishing: Metal parts such as gears and bearings.

- Finishing: Surface finishing of furniture and wooden crafts.

- Shape Cutting: Plastic parts.

- Engraving: Fine engraving on jewelry like rings and necklaces.

- Repair Work: Drilling holes in automobile body panels.

Principle of Radial Drilling Machinery

Radial Drilling Machinery operates as follows:

1. Fixing the Workpiece

First, fix the workpiece to the table using a clamp or vise.

2. Selection and Installation of Cutting Tools

Select and mount the appropriate cutting tool (e.g., end mill, drill) on the spindle.

3. Setting Cutting Conditions

Set cutting conditions based on the material and tool characteristics. These include rotation speed, feed rate, and cutting depth for efficient and precise cutting.

4. Start Cutting

Begin cutting by rotating the main axis and advancing the cutting tool towards the workpiece.

5. Continuation and Progress of Cutting

Adjust the cutting tool speed and depth based on the changing shape and dimensions of the workpiece.

6. End of Cutting and Finishing

Stop the cutting tool once the desired shape or dimension is achieved. For surface finishing, replace the cutting tool with a finishing tool like an abrasive head or buffing tool.

Radial Drilling Machinery Structure

While structures vary, the basic components are as follows:

1. Base

The base stabilizes the machine and has bolt holes for securing it to the floor.

2. Column (Strut)

A column rises from the base, providing rigidity and accuracy for vertical tool movement.

3. Arm (Radial Arm)

The arm moves along the column, changing the tool’s position. It’s equipped with a tool holder.

4. Table

A flat plate for fixing the workpiece, equipped with clamps and bolt holes.

5. Drill Head

Holds the tool in place and is adjustable.

6. Motor

An electric motor rotates the drill head, with adjustable speed.

7. Spindle (Rotary Axis/Spindle)

The spindle mounts and rotates the tool. It may include a chuck or clamp.

Some models feature a rotating table or replace the table with the base.

Other Information on Radial Drilling Machinery

1. Advantages

Radial drilling machinery is suitable for large, heavy workpieces and offers ease of operation and versatility in material handling.

2. Disadvantages

Limited to specific cutting operations, these machines may have accuracy limitations and can generate noise and vibration, especially with large workpieces. Their size may also require more space.

3. Range of Applications

Applicable for drilling, chamfering, grooving, threading, engraving, pattern cutting, and other detailed work.

4. Types of Cutting Tools

Uses tools like drill bits and end mills.

5. Cutting Speed and Feed Rate

Adjust the cutting speed and feed rate according to the material type and cutting tool for optimal machining quality.