What Is Bending Machinery?

Bending machinery is a processing machine used to bend thin sheet metal materials.

Bending machinery goes by a variety of names, including brake presses, benders, and bending machines. The mechanism of this machine itself is simple. Similar to a press machine, the punch die (upper die) and die block (lower die) are moved up and down to apply pressure and bend the metal sheet.

By applying vertical pressure and preparing dies that match the hardness, thickness, and bending angle of the material, it is possible to bend the material to the desired angle.

Uses of Bending Machinery

Bending machinery is used to produce shapes that are difficult to cut or to cut costs. A wide variety of products are produced using bending machinery, ranging from home appliances to automobile parts, industrial products, and parts for building materials such as aluminum sashes.

Products using these machines are made from thin metal materials, which are lightweight and can be produced in large quantities. In most cases, bending machinery is used to bend thin metal materials.

Principle of Bending Machinery

As mentioned above, the bending machinery itself is simple. Similar to a press, the punch die (upper die) and die block (lower die) are moved up and down to apply pressure and bend the metal sheet. Currently, the hydraulic press brake is the most major processing machine.

In this machine, the hydraulic cylinder will serve as the power structure for the vertical movement. The load and processing speed can be controlled because the crank part does not protrude too much.

The disadvantage of bending is that bending accuracy may vary due to springback caused by plastic deformation, which is a characteristic of bending metal under pressure. Spring back refers to the phenomenon of metal returning to its original shape.

Other Information on Bending Machinery

Types of Bending Machines

When using bending machinery, it is necessary to understand the types of bending that are possible. There are various types of upper and lower dies, and complex bending processes can be realized by combining parts.

The bending methods mainly used are as follows:

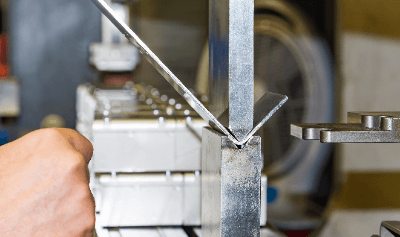

1. V-Bending

V-bending is a processing method that literally uses a V-shaped punch to push and bend a metal sheet. The die is simple and used for various bending processes. V-bending is classified into the following three types according to the degree of punching pressure.

- Bottoming Bend (Bottoming Bend)

A 90-degree bend in which the bend is pushed all the way to the bottom of the punch. - Partial Bending (Free Bending)

A method of adjusting the bending angle by stopping the V-bend in the middle of the punch. - Coining Bend (Pressure Bend)

A method of applying more pressure after the punch is pressed to the bottom like a bottoming bend.

Generally, in V-bending, the more pressure is applied, the smaller the bending R and springback becomes. Therefore, the coining bend can perform the most precise processing, but it requires 5 times more pressure than the bottoming bend to apply pressure, and the die is subject to severe wear.

2. L-Shape Bending

L-shape bending is a processing method to bend a metal sheet at right angles by clamping the top and bottom of the sheet and pressing the protruding part with a punch. It is also called “hold down bending.” Since the sheet is bent while being held down, the forming process is more stable than V bending. It is also possible to bend long metal sheets that cannot be bent with V-bending.

3. U-Bending

U-bending is a processing method in which pressure is applied to a metal sheet while holding it with a punch from above and a movable pad from below, and the sheet is bent into a U-shape in line with the fixed platforms on either side during processing. Since there is little variation in bending accuracy and forming is possible with a single bending, man-hours required for bending can be reduced.

However, a dedicated die is required for each shape when forming, and the startup cost is high.

4. Z-Bending

Z-bending is a processing method to bend a metal sheet into a Z-shape. z-bending is a method to bend a metal sheet into a Z-shape by either performing L-bending twice as described above (once bent, the reverse side of the sheet is reversed and bent again) or by bottom-bending with a special punch during L-bending and pushing the sheet once.

Forming once is more accurate than L-bending twice, but the cost is naturally higher.