What Is Thermal Grease?

Thermal grease is a highly thermally conductive grease used to help dissipate heat from components and electronic devices that generate high heat.

Thermal grease is a highly thermally conductive grease used to help dissipate heat from components and electronic devices that generate high heat.

It is used at the connection between a heat source that generates heat and a device that diffuses heat, such as a heat sink.

Uses of Thermal Grease

Thermal grease is used in semiconductor devices, such as power transistors, CPUs, and GPUs, to dissipate heat generated by electrical resistance quickly. Cooling these devices is essential because excessive heat can degrade device performance and cause device failure.

In personal computers, it is used to improve heat conduction between the CPU and the heat sink. They are also used in ECUs in hybrid and electric vehicles to improve the speed of heat dissipation of electronic devices. It is also used in LED lighting and other devices with high luminance or large size for the purpose of heat dissipation of electronic devices.

Principle of Thermal Grease

At the joint between a heat source and a heat sink or other heat-dissipating component, there are slight distortions of the joint surface and minute irregularities on the joint surface. This generally results in an air gap or space between the two.

Since air is extremely adiabatic, the thermal resistance of the junction is extremely high, which reduces the efficiency of heat transfer during heat dissipation. Thermal grease will fill these gaps and spaces, thereby maximizing heat transfer at the junction.

Structure of Thermal Grease

Thermal grease is made by dispersing inorganic particles with high thermal conductivity in a viscous, low-volatility oil-like component (grease) to achieve high thermal conductivity. Because of its high viscosity and easy handling, it is used in a wide range of fields related to heat dissipation and heat conduction.

The characteristics of thermal grease and its thermal conductive filler are as follows:

1. Grease

Silicone grease is often used because of its low-viscosity change with temperature. Silicone grease is characterized by its high heat resistance, chemical stability, and excellent water resistance. For this reason, it is widely used as a sealing material and adhesive, in addition to high-temperature environments and lubrication applications.

Since thermal grease is often exposed to high temperature environments, silicone grease is one of the most suitable materials because of its low viscosity change, high heat resistance, and chemical stability.

2. Thermally Conductive Filler

In thermal grease, metal or metal oxide particles with high thermal conductivity are mixed into the base grease. Metal particles such as aluminum, copper, silver, or metal oxide particles such as alumina, magnesium oxide, or aluminum nitride are used. These are dispersed in a manner appropriate to their respective particle diameters.

When metallic particles are used, not only thermal conductivity but also electronic conductivity is exhibited. Therefore, for applications where electronic conductivity is not desired, thermal grease using metal oxide particles is the only choice. In addition, metal oxide particles are often used due to their chemical stability, as metal is easily oxidized and its physical properties tend to change.

The ratio of these two materials mixed together determines the electrical properties and thermal conductivity. Based on the ratio, the properties of each thermal grease will vary. For example, thermal grease with a high concentration of filler has a higher thermal conductivity than one with a lower concentration.

Also, thermal grease has the property of degrading and hardening over time, even though it has moderate viscosity immediately after application. Depending on the difference in expansion coefficients of the materials to be joined, cracks may appear, resulting in reduced thermal conductivity characteristics.

Other Information on Thermal Grease

How to Use Thermal Grease

The basic instructions for using thermal grease are as follows:

1. Cleaning

Before applying thermal grease, the area to be coated must be cleaned. If there is a dirt or oil film, use detergent or solvent to remove it.

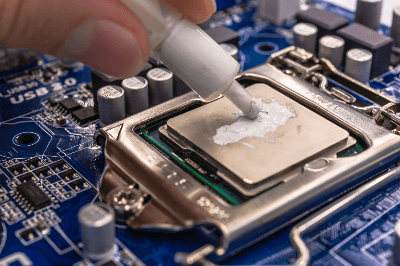

2. Applying Thermal Grease

Take out an appropriate amount of thermal grease and apply it to the desired area. The role of thermal grease is to fill the gap in the air layer and conduct heat efficiently. Excessive amount of thermal grease may cause poor heat transfer due to the increased thickness and longer heat conduction distance, and may cause size defects in the assembly of the component.

3. Confirmation After Application

After applying thermal grease, check that the applied area is sufficiently covered with thermal grease. It is also important to wipe off any excess thermal grease.

4. Assembly

Assemble the necessary parts at the locations where thermal grease has been applied. When assembling, it is important to do so in the correct order, referring to the instructions.