What Is a Bearing Roller?

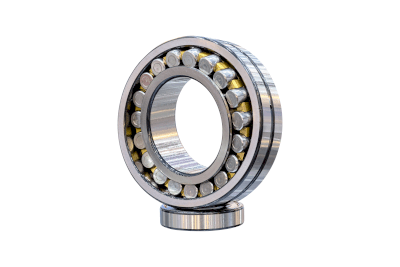

A bearing roller is a bearing that uses cylindrical rollers instead of balls as the rolling elements that support the load while rolling inside the bearing.

Bearing rollers with a larger diameter are called rollers, while those with a smaller diameter are called needles or needle rollers. Compared to ball bearings, which use a rolling element (ball), a bearing roller can support higher loads. There are various types of bearing rollers, depending on the application.

Uses of Bearing Rollers

Compared to ball bearings, bearing rollers can support larger loads and are used in automobiles and industrial machinery. The applications vary depending on the type.

1. Thrust Needle Bearing Roller

Thrust needle bearing rollers are used to support axial loads between parts rotating relative to each other in a planetary gear mechanism (planetary gears).

2. Needle Bearing Roller

Needle bearing rollers are used in the crankshafts of competitive bicycles. While ball bearings are used in the crankshafts of bicycles for daily use, needle bearings, and ball bearings are used in competition bicycles to reduce size and weight.

3. Tapered Bearing Roller

Tapered bearing rollers are used in the transmissions of automobiles. Automatic transmissions for front-wheel drive have a large gear on the final reduction shaft, and these gears are usually helical. The teeth of the helical gears are slanted to reduce noise and vibration when the gears mesh, but they also generate forces in three directions. The role of the tapered bearing roller is to support the forces in these three directions.

Planetary gears are also used in multi-stage step-type automatic transmissions, the forward/reverse switching mechanism of continuously variable transmissions (CVTs), and some sub-transmissions. The pinion in planetary gears is supported by a needle roller. Although the pinions are usually beveled, the needles can only support loads in two directions. The remaining thrust load is not supported by the needle, but by a washer on the end face of the pinion.

Principle of Bearing Rollers

In general, bearing rollers can support larger loads than ball bearings. The reason for this is bearing rollers have a cylindrical rolling element that makes linear contact with the inner and outer rings and raceways with which it comes into contact.

Since ball bearings are in point contact, the bearing roller has a larger contact area. The larger contact area reduces the stress (Hertzian stress) generated at the contact area.

The shape of the bearing can be cylindrical or conical, and changing this shape also changes the amount of load that the bearing can support. This also makes it possible to increase the load that can be supported by a single bearing without using multiple bearings, thus enabling compact specifications through weight reduction and miniaturization.

Types of Bearing Rollers

Similar to ball bearings, bearing rollers can be broadly classified into two types: radial bearings, which support radial loads (perpendicular to the axis of rotation), and thrust bearings, which support thrust loads (in the same direction as the axis of rotation). Bearings with relatively large rollers are called bearing rollers, while bearings with narrower rollers are called needle bearing rollers. Typical types are as follows:

1. Radial Bearing Roller

Radial bearing rollers are capable of bearing radial loads acting at right angles to the shaft. Compared to ball bearings, which use balls instead of rollers, radial bearing rollers can support larger radial loads. By changing the shape of the rollers, a wider variety of types is available.

2. Needle Bearing Roller

A needle roller is used as the rolling element between the inner and outer rings of a bearing roller. By making the rolling element as thin as a needle, the height of the cross section is smaller than that of a bearing roller, contributing to the reduction of machine weight and size. In addition to radial bearings, thrust bearings are also available and are used in a variety of applications, including automobiles and electrical machinery.

3. Taper Bearing Rollers

Tapered bearing rollers are radial bearing rollers with tapered rollers and sloped raceways on the inner and outer rings instead of flat. The tapered rollers and beveled raceways can support large radial loads and large thrust loads at the same time.

It is mainly suitable for supporting loads in three directions generated by helical gears. However, a single bearing can only support thrust loads in one direction. It is common to use a combination of two tapered bearing rollers in opposite directions.