What Is a Sight Glass?

A sight glass is a device used to monitor the flow of a fluid or the position of a liquid surface.

In flow monitoring applications, it is sometimes called a “sight flow,” “flow sight,” or “sight flow indicator,” and its purpose is to monitor the presence or absence of fluid flow in a pipe and the degree of flow rate. In liquid level confirmation applications, also sometimes called “site flow gauges,” the purpose is to monitor the position (level) of the liquid level.

The shape, construction, and installation methods of the instruments for the above two applications differ greatly.

Uses of Sight Glasses

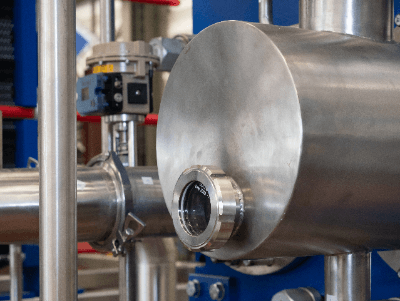

Figure 1. Example of sight glass use

Sight Glasses, as mentioned above, have the following two applications:

1. Fluid Flow Monitoring

In the case of fluid flow monitoring, sight glasses are connected to the piping laid in power plants and factories by flanges or threaded connections. The flow of various liquids such as steam, water, and chemicals through the piping is monitored visually by operators and maintenance workers.

2. Liquid Level Position Monitoring

Sight glasses for liquid level position monitoring are screwed or hammered (fitted) into holes on the side of the housing of machines that use reduction gears or bearings. The operator or maintenance worker visually checks the correct fluid level and the correct amount of lubrication.

Principle of Sight Glass

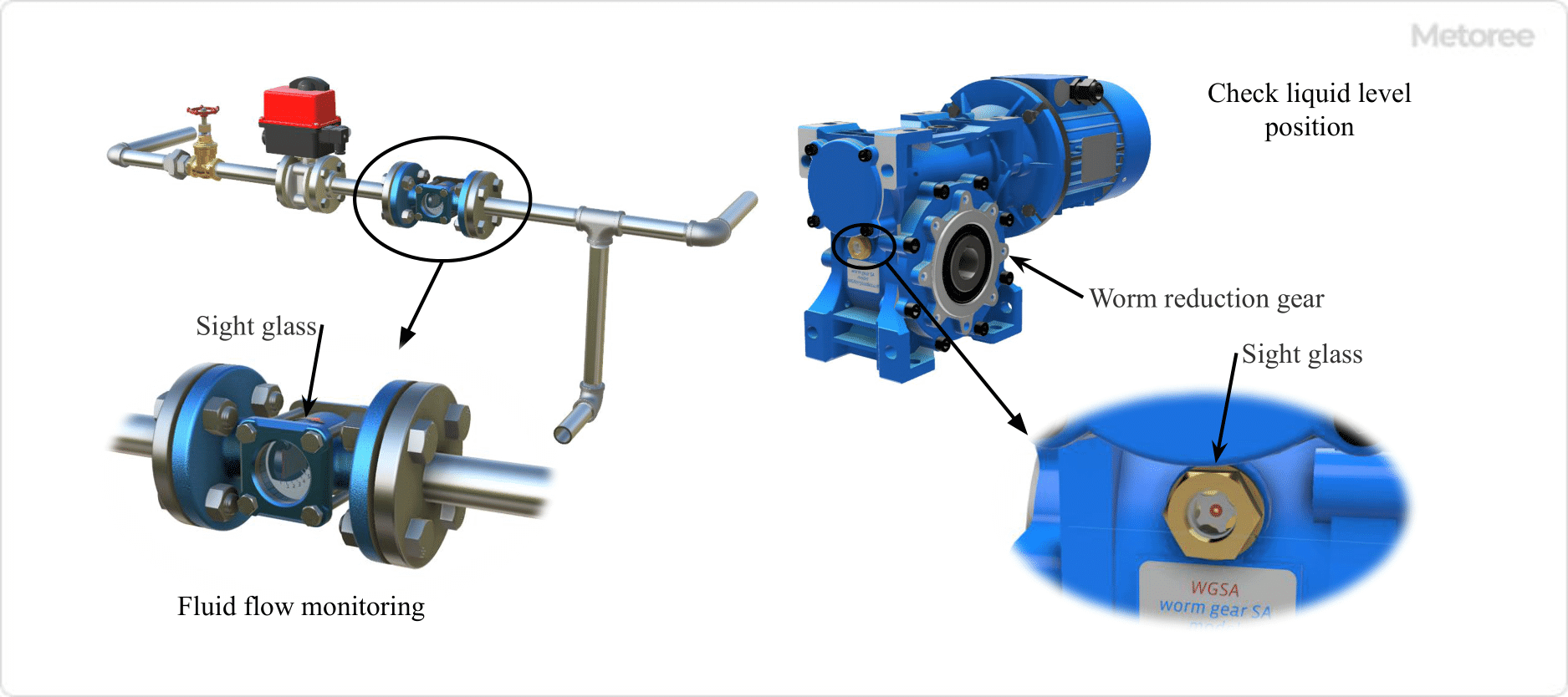

Figure 2. Principle of sight glass

The principle of sight glasses depends on the above two applications.

1. Fluid Flow Monitoring

Sight glasses for fluid flow monitoring are designed to provide visibility in the following two major ways:

- Visually confirming the state of fluid flow with vortices and bubbles.

- Visually checking the fluid flow by rotating flaps or impellers

2. Monitoring the Liquid Level Position

A sight glass for monitoring the liquid level position is installed at the correct position (level) of the liquid, such as oil, and when the liquid level reaches the position where the sight glass is installed, the liquid enters the sight glass to check the liquid level.

Typically, sight glasses are filled with oil or other fluids to maintain the fluid level near the center position. However, if the entire interior of the sight glass is filled with liquid, it indicates that an excessive amount of oil has been supplied.

Structure of Sight Glasses

The types of sight glasses by construction are as follows:

1. For Fluid Flow Monitoring

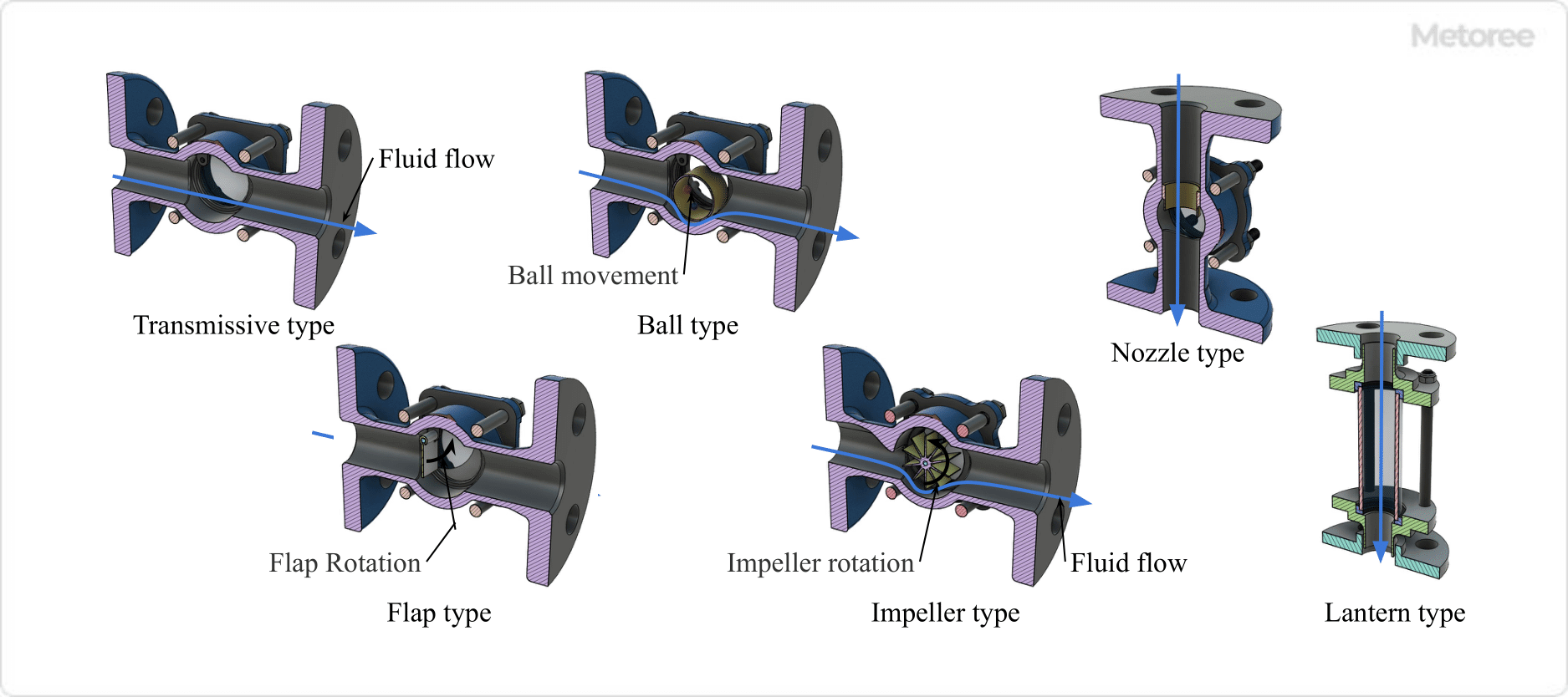

Figure 3. Types of site glasses for flow monitoring

Transmissive

There is no special mechanism inside the transparent sight glass, and the fluid is checked by the vortex and bubbles as it passes through the sight glass. When used with two fluids, the mixing state can be checked by the color of the fluid.

Flap Type

Inside a flap-type sight glass, a plate called a flap is attached to a pin or another shaft. The angle of the flap changes in response to the fluid flow, allowing for the inspection of the flow condition. The higher the flow rate, the closer the angle of the flap becomes to horizontal.

Ball Type

The ball-type sight glass has several balls inside, which float and rotate in response to the fluid flow to check the flow condition. The higher the flow rate, the faster the balls move.

Impeller Type

An impeller is mounted inside the impeller-type sight glass. The impeller rotates in response to the fluid flow, allowing for the inspection of the flow condition. The higher the flow rate, the faster the impeller rotates.

Nozzle Type

Inside the nozzle-type sight glass is a pipe-like object called a nozzle, which checks the fluid dripping from the nozzle. The nozzle-type is characterized by less contamination of the glass because the fluid does not come in contact with the glass. This type is for small flow rates and is installed in vertical piping. The flow direction is limited to top-to-bottom.

Lantern Type

The main body of the lantern-type sight glass is made of glass in the shape of a pipe, allowing the flow to be checked from any direction in 360°. When used for liquids, it is characterized by minimal liquid residue and is suitable for monitoring the flow of not only liquids but also powders and other materials. This type is also limited to installation in vertical piping and use in the flow direction from top to bottom.

2. For Monitoring Liquid Level Position

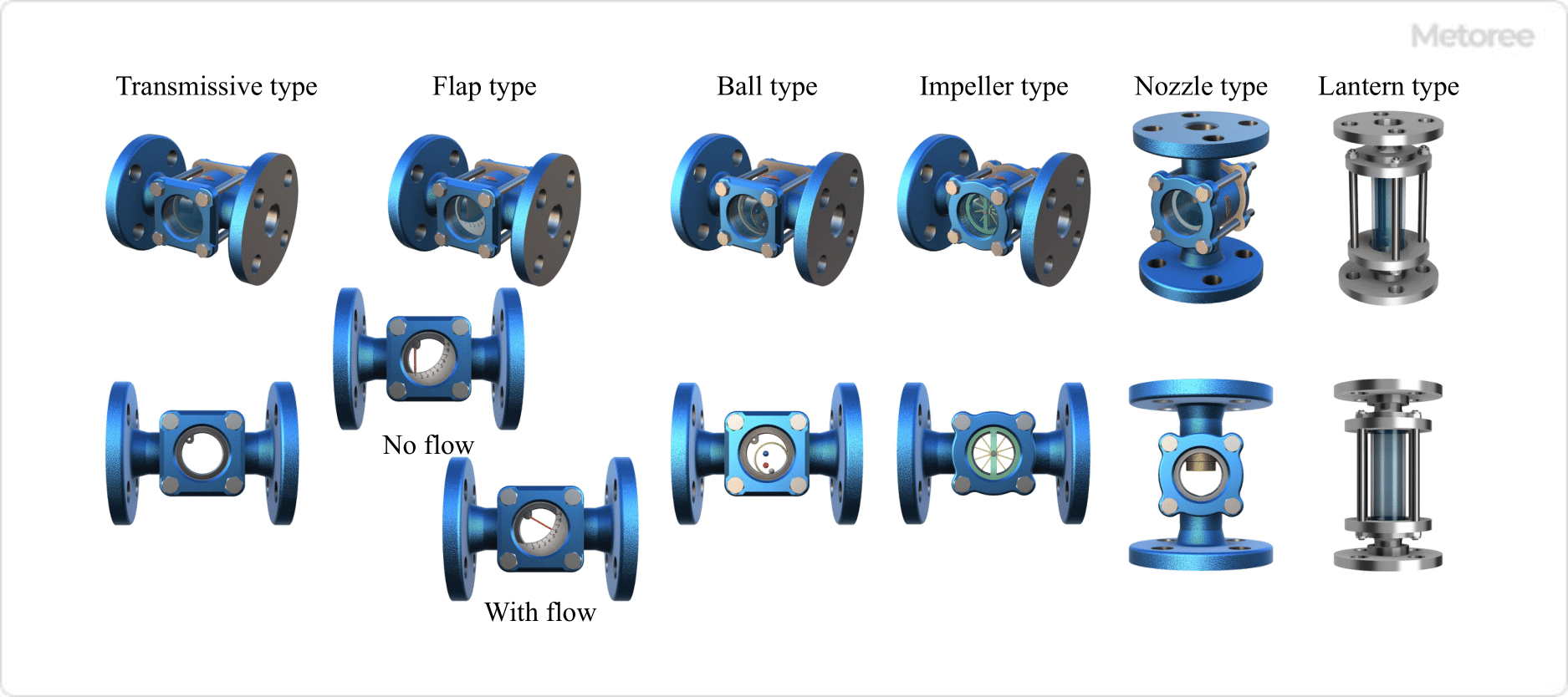

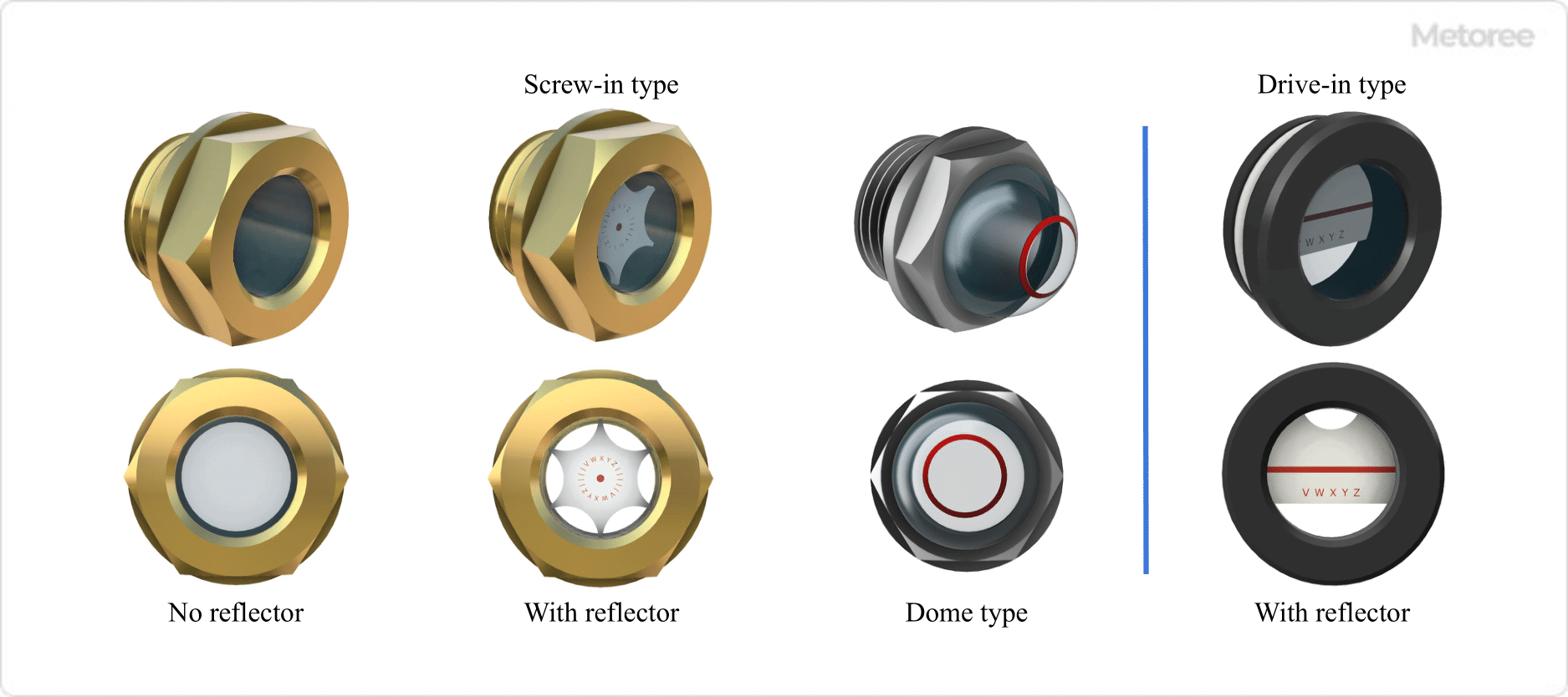

Figure 4. Types of sight glasses for monitoring liquid level position

Screw-in Type

The screw-in type sight glass is installed by screwing it into a threaded screw machined into a reducer housing or the like. There are two types of sight glasses: one with a reflective plate for easy visibility and one without a reflective plate.

Hammer-in Type

The sight glasses are installed by fitting them into a simple hole machined into the reducer housing or the like. As with the screw-in type, there are two types: one with a reflective plate inside the sight glasse and one without.

Dome Type

The dome-type sight glass has a hemispherical, domed glass surface and is mounted by screwing it in.

Other Information on Sight Glasses

1. Materials of Sight Glass

Typical materials used for sight glasses are as follows:

For Fluid Flow Monitoring (Main Part):

- Gray cast iron JIS G5501 FC200, etc.

- Spheroidal graphite cast iron (ductile cast iron) JIS G5502 FCD450, etc.

- High-temperature, high-pressure cast steel JIS G5151 SCPH2, etc.

- Stainless steel castings JIS G5121 SCS13A, 14A, etc.

- Bronze castings JIS H5120 CAC406, etc.

- Others Lining or coating on internal fluid passage parts, etc.

For Liquid Level Position Monitoring:

- Carbon steel, stainless steel, resin, etc.

Glass used for windows is made of different materials depending on the type of fluid used, pressure and temperature.

For fluid flow monitoring, tempered glass is used, while borosilicate glass is used for high temperature applications. Polycarbonate resin (PC) or tempered glass is used for fluid level position monitoring.

2. Standards

Sight glasses are subject to the following standards:

- JIS F7218 Shipbuilding-Cylindrical sight glasses

- JIS F7234 Shipbuilding-Flat sight glasses

3. Notes on Selection and Specifications

In the condensate discharge piping of steam piping, sight glasses are sometimes installed aft of pressure gauges, ball valves, globe valves, condensate recovery devices, strainers, steam traps, pressure reducing valves, check valves, solenoid valves, and the like. This causes problems such as inability to accurately measure flow rates due to water hammer, flash steam, and cavitation before reaching the sight glass.

Another problem when using the sight glass with high-temperature fluid is that the steam also makes the sight glass hot. When the temperature drops due to rapid cooling, the glass part of the sight glass can be damaged by thermal shock or other causes. Therefore, it is necessary to select the model and especially the glass material in consideration of the location and environment where the sight glass is to be installed.