What Is an Oil Separator?

An oil separator is a device that separates oil and water or oil and gas.

There are two main types of oil separators: one is an oil-water separator that removes solid particles and water mixed in the oil, and the other is a gas separator that removes gases dissolved in the oil. However, the latter is often referred to as an Oil Separator.

The former is often used to remove oil contained in wastewater, while the latter is used to separate gases mixed in lubricating oil such as engine oil.

Without the former type Oil Separator, oil can mix with wastewater in industrial activities such as ships and factories, adversely affecting the environment. Without the latter type of Oil Separator, air and blow-by gases can mix with the lubricating oil, degrading the performance of the lubricating oil and reducing the heat dissipation efficiency of the oil cooler.

Uses of Oil Separators

Oil Separators are widely used in internal combustion engines and compressors. Applications are divided into oil-water separators and gas separators.

1. Oil-Water Separator

Oil-water separators are used to separate engine oil and heavy oil discharged from ship engines and boilers to reduce the impact on the marine environment. They are also used in factories to separate oil from industrial oil, cooling water, cleaning fluids, etc. for wastewater treatment and recycling. In the production processes of pharmaceuticals, cosmetics, and food products, they are sometimes used to separate oil.

2. Gas Separator

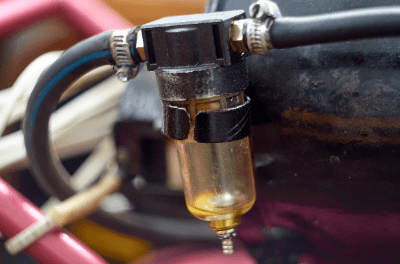

Gas separators are mainly used to separate oil in internal combustion engines and refrigeration circuits. In both cases, oil and gas are stirred up by crank parts that rotate at high speeds, creating an environment where gas can easily mix with oil. By using a gas separator, it is possible to control oil loss and maintain lubrication and heat dissipation characteristics.

They are also used to prevent rusting of machine parts by removing oxygen contained in gases.

Principle of Oil Separator

The principle of Oil Separator differs between Oil/Water Separator and Gas Separator.

1. Oil-Water Separator

Oil-water separators use the fact that oil and water have different specific gravities to separate them by making the oil float. Generally, oil-water separators are composed of internally installed plates, mesh, or coiled tubing. These components remove oil as the liquid passes through them, separating the oil from the liquid.

The liquid is filtered as it passes through the structure, and the oil is floated and separated as it is trapped by the structure. The oil is then stored in a separate tank and the liquid is discharged after being processed.

2. Gas Separator

Gas separators use methods such as decompression, heating, and diffusion to separate gases from liquids in which they are dissolved.

Generally, a gas separator uses a vacuum pump to reduce the pressure in a tank containing oil. The gas dissolved in the liquid is then separated from the oil, and the gas bubbles in the liquid are reduced.

In addition, heating and diffusion methods can be used in combination to achieve more efficient gas separation. The gases are then stored in a separate tank and the liquid is discharged after being processed.

How to Select an Oil Separator

When selecting an Oil Separator, keep the following points in mind:

1. Oil-Water Separator

It is important to confirm the type and amount of oil and water to be separated and select an oil-water separator with the appropriate capacity. Separation capacity is affected by the size of oil droplets, the way liquid flows, the density and viscosity of oil, and the difference in specific gravity between oil and water. Therefore, it is necessary to select an oil-water separator that matches the operating environment and conditions.

2. Gas Separator

The performance of a gas separator includes the type and concentration of the gas to be separated and the purity of the gas after separation. These considerations should be taken into account when selecting the appropriate performance of the separator.

The separation methods of gas separators include diffusion separation, centrifugal separation, gravity separation, and condensation separation. Depending on the characteristics of each, the appropriate gas separator must be selected for the intended purpose.

The flow rate of the gas separator should also be taken into consideration. It is necessary to select a gas separator with an appropriate flow rate according to the flow rate of the gas to be treated.